Application of Titanates as Flame Retardants in Flame Retardant Thermoplastics

A technology of thermoplastics and titanates, applied in ethylene-vinyl acetate, in the field of flame-retardant thermoplastic polyurethane elastomers and polypropylene, to achieve good dispersion and non-migratory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

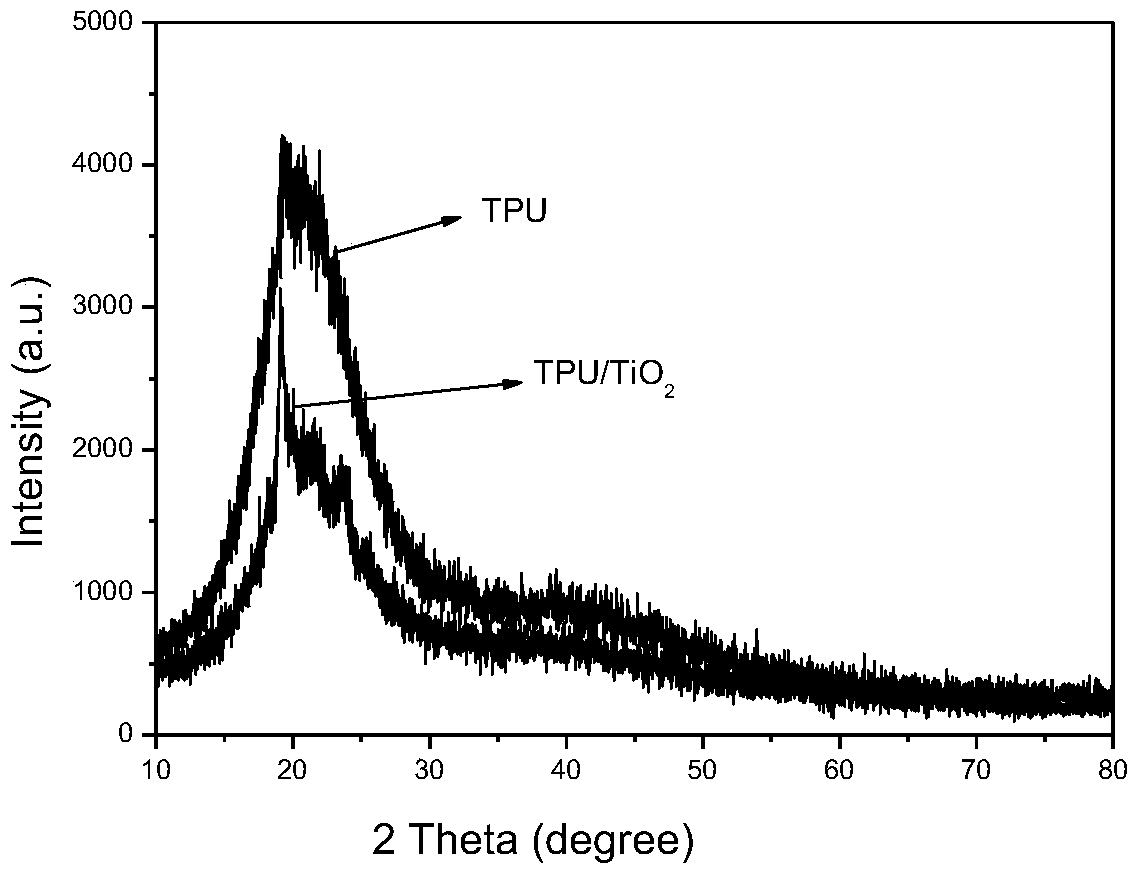

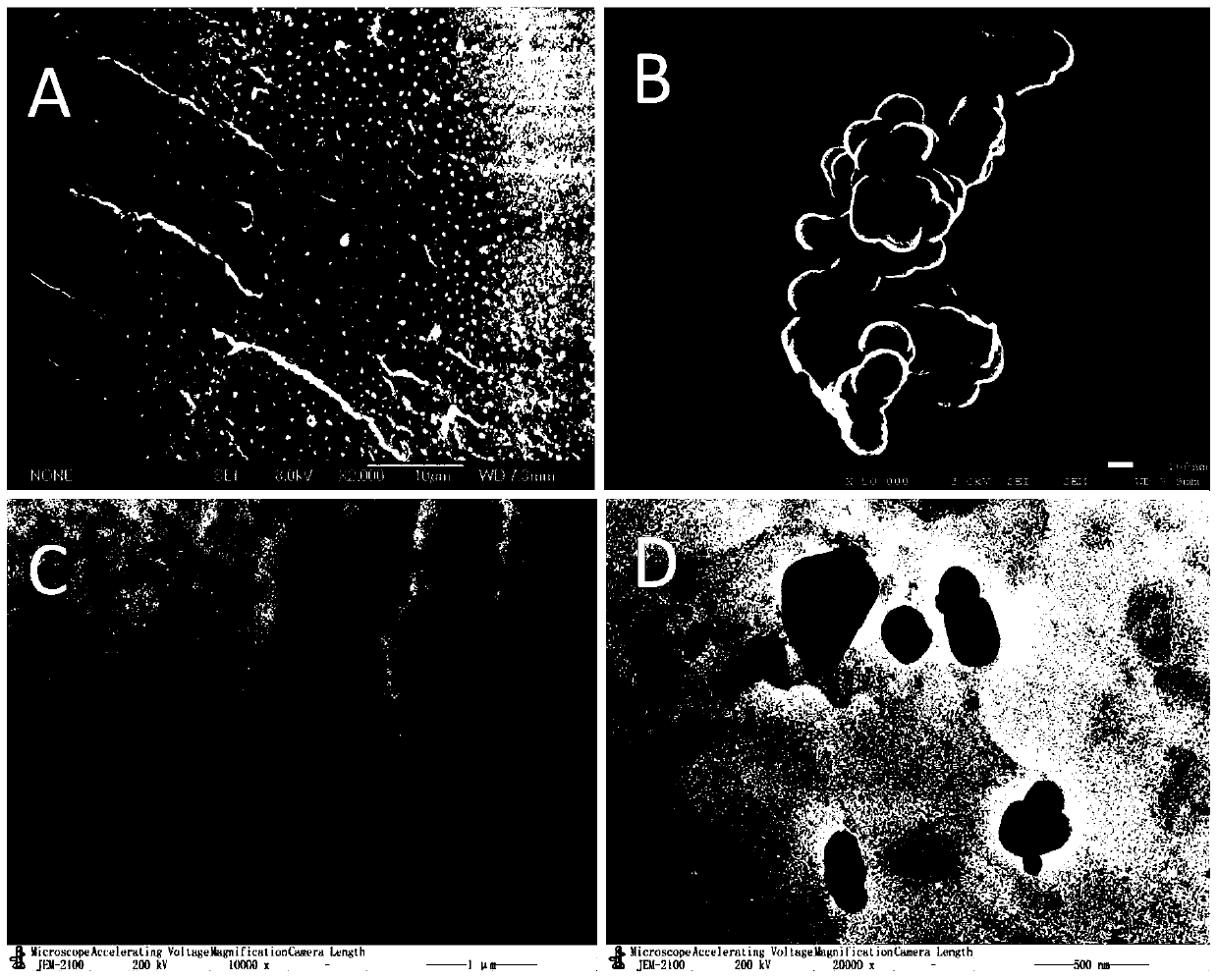

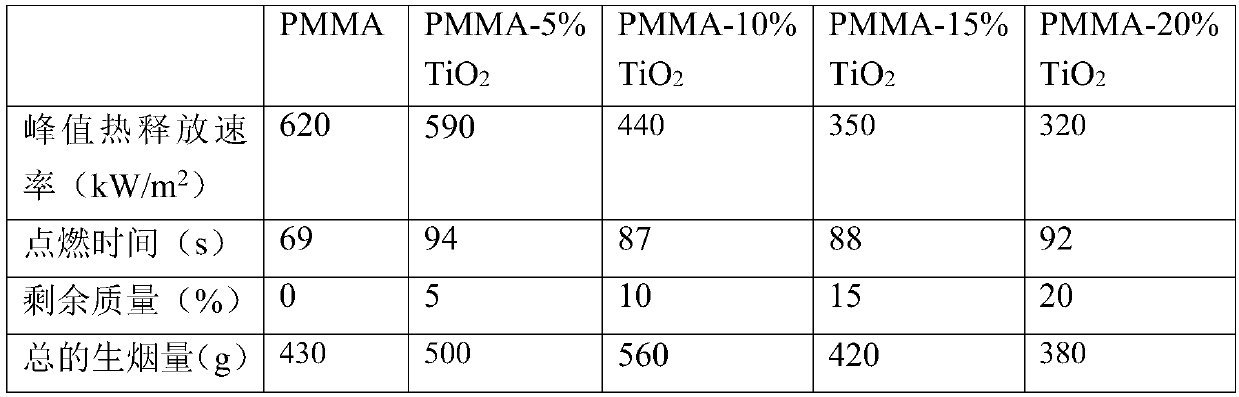

[0066] Titanate compounds were used as flame retardants to prepare flame retardant thermoplastic polyurethane elastomer composite material-1.

[0067] The titanate compound is n-butyl titanate.

[0068] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0069] 1) Preparation of masterbatch. The masterbatch is composed of thermoplastic polyurethane elastomer and n-butyl titanate. In parts by weight, the thermoplastic polyurethane elastomer is 90 parts, and n-butyl titanate is 10 parts. The temperature of the internal mixer was controlled at 180°C, and the rotational speed was 30 rpm. The thermoplastic polyurethane elastomer was added into the internal mixer, and after it was melted, a certain amount of n-butyl titanate was added, and melt blended for 10 minutes. The high-concentration flame-retardant TPU / n-butyl titanate masterbatch is obtained and stored in a sealed bag.

[0070] 2) The temperature of the internal mixe...

Embodiment 2

[0076] Titanate compounds were used as flame retardants to prepare flame retardant thermoplastic polyurethane elastomer composite material-2.

[0077] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0078] 1) the preparation of masterbatch, with embodiment 1;

[0079] 2) The temperature of the internal mixer is controlled at 180°C, the rotating speed is 30 rpm, and thermoplastic polyurethane elasticity with a mass percentage of 97.5 wt% is added to the internal mixer, and a high concentration of 2.5 wt% is added after it is melted The flame-retardant thermoplastic polyurethane elastic masterbatch was melt-blended for 10 minutes, and the composite material was taken out and pressed into shape.

[0080] 3) The obtained material is placed in a constant temperature and humidity test box (25°C, 60% relative humidity) for 72 hours before performance testing.

[0081] To step 3) the flame-retardant composite material of ga...

Embodiment 3

[0083] Titanate compounds were used as flame retardants to prepare flame-retardant thermoplastic polyurethane elastomer composite-3.

[0084] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0085] 1) the preparation of masterbatch, with embodiment 1;

[0086] 2) The temperature of the internal mixer is controlled at 180° C., the rotating speed is 30 rpm, and thermoplastic polyurethane elasticity of 95 wt % is added to the internal mixer, and a high concentration of 5 wt % is added to the internal mixer after it is melted. Burn the thermoplastic polyurethane elastic masterbatch, melt and blend for 10 minutes, take out the composite material and press it into shape.

[0087] 3) The obtained material is placed in a constant temperature and humidity test box (25°C, 60% relative humidity) for 72 hours before performance testing.

[0088] To step 3) the flame-retardant composite material of gained is pressed into 100 * 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com