Application of Silane Coupling Agent as Flame Retardant in Flame Retardant Thermoplastics

A thermoplastic and silane coupling agent technology, applied in flame-retardant thermoplastic polyurethane elastomer, ethylene-vinyl acetate, polypropylene field, to achieve the effect of not easy migration, good compatibility and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

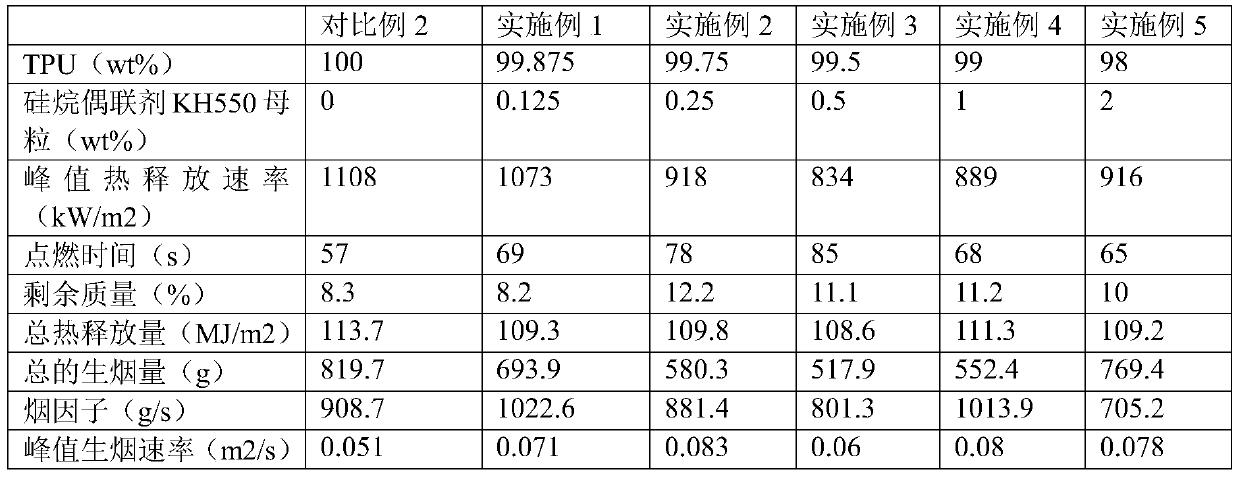

Embodiment 1

[0027] Silane coupling agent compounds were used as flame retardants to prepare flame retardant thermoplastic polyurethane elastomer composite material-1.

[0028] The silane coupling agent compound is silane coupling agent KH550.

[0029] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0030] 1) Preparation of a masterbatch, the masterbatch is composed of a thermoplastic polyurethane elastomer and a silane coupling agent KH550, in parts by weight, 90 parts of the thermoplastic polyurethane elastomer and 10 parts of a silane coupling agent KH550. Control the temperature of the internal mixer at 180°C and the rotational speed at 30 rpm, add thermoplastic polyurethane elastomer into the internal mixer, add a certain amount of silane coupling agent KH550 after it melts, and melt blend for 10 minutes. Obtain high-concentration flame-retardant TPU / silane coupling agent KH550 masterbatch, put it in a ziplock bag and seal i...

Embodiment 2

[0035] Silane coupling agent compounds were used as flame retardants to prepare flame retardant thermoplastic polyurethane elastomer composite material-2.

[0036] The silane coupling agent compound is silane coupling agent KH550.

[0037] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0038] 1) the preparation of masterbatch, with embodiment 1;

[0039]2) Control the temperature of the internal mixer at 180°C, and the rotating speed is 30 rpm, and add thermoplastic polyurethane elastic with a mass percentage of 99.75 wt% into the internal mixer, and add a high concentration of 0.25 wt% after it is melted The flame-retardant thermoplastic polyurethane elastic masterbatch was melt-blended for 10 minutes, and the composite material was taken out and pressed into shape.

[0040] 3) All the prepared samples were placed in a constant temperature and humidity test box (25° C., relative humidity 60%) for 72 hours before p...

Embodiment 3

[0043] Silane coupling agent compounds were used as flame retardants to prepare flame retardant thermoplastic polyurethane elastomer composite material-3.

[0044] The silane coupling agent compound is silane coupling agent KH550.

[0045] The preparation method of the flame-retardant thermoplastic polyurethane elastomer composite material is:

[0046] 1) the preparation of masterbatch, with embodiment 1;

[0047] 2) The temperature of the internal mixer is controlled at 180°C, the rotating speed is 30 rpm, and thermoplastic polyurethane elasticity with a mass percentage of 99.5 wt% is added to the internal mixer, and a high concentration of 0.5 wt% is added after it is melted The flame-retardant thermoplastic polyurethane elastic masterbatch was melt-blended for 10 minutes, and the composite material was taken out and pressed into shape.

[0048] 3) All the prepared samples were placed in a constant temperature and humidity test box (25° C., relative humidity 60%) for 72 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com