Flame-retardant composite material containing mesoporous titanium dioxide-hydrotalcite hybrid material, and preparation method thereof

A technology of mesoporous titanium dioxide and flame retardant composite material, applied in the field of flame retardant ethylene-vinyl acetate copolymer modification, can solve the problems of poor flame retardant effect and smoke suppression performance of flame retardant materials, and achieve the effect of reducing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

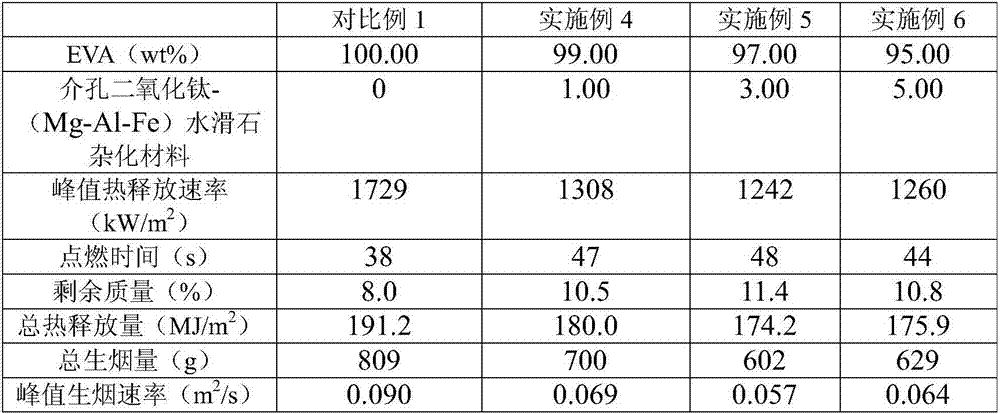

Examples

Embodiment 1

[0020] Example 1 Preparation method of flame retardant composite material of mesoporous titanium dioxide-hydrotalcite hybrid material

[0021] (1.1) The temperature of the internal mixer is controlled at 135° C., the rotating speed is 30 rpm, and ethylene-vinyl acetate copolymer with a mass percentage of 99.00 wt % is added to the internal mixer and melted for 5 minutes;

[0022] (1.2) After the ethylene-vinyl acetate copolymer is completely melted, the mesoporous titanium dioxide-magnesium iron hydrotalcite hybrid material with a mass percentage of 1.00wt% is slowly added to the internal mixer, and the two are melted and blended for 5 minutes, and the material is taken out and pressed. forming;

[0023] (1.3) The materials taken were placed in a constant temperature and humidity environment before performance testing, maintaining a temperature of 25°C and a relative humidity of 60% for 48 hours.

[0024] Press the flame retardant composite material of step (1.3) gained into ...

Embodiment 2

[0025] Example 2 Preparation method of flame retardant composite material of mesoporous titanium dioxide-hydrotalcite hybrid material

[0026] (1.1) The temperature of the internal mixer is controlled at 135° C., the rotating speed is 30 rpm, and ethylene-vinyl acetate copolymer with a mass percentage of 97.00 wt % is added to the internal mixer and melted for 10 minutes;

[0027](1.2) After the ethylene-vinyl acetate copolymer is completely melted, the mesoporous titanium dioxide-(Mg-Fe)hydrotalcite hybrid material with a mass percentage of 3.00wt% is slowly added to the internal mixer, and the two are melted and blended for 15 minutes , take out the material and press it into shape;

[0028] (1.3) The materials taken were placed in a constant temperature and humidity environment before performance testing, maintaining a temperature of 25°C and a relative humidity of 60% for 48 hours.

[0029] Press the flame retardant composite material of step (1.3) gained into 100 × 100 ×...

Embodiment 3

[0030] Example 3 Preparation method of flame retardant composite material of mesoporous titanium dioxide-hydrotalcite hybrid material

[0031] (1.1) The temperature of the internal mixer is controlled at 135° C., the rotating speed is 30 rpm, and ethylene-vinyl acetate copolymer with a mass percentage of 95.00 wt % is added to the internal mixer and melted for 8 minutes;

[0032] (1.2) After the ethylene-vinyl acetate copolymer is completely melted, the mesoporous titanium dioxide-(Mg-Fe)hydrotalcite hybrid material with a mass percentage of 5.00wt% is slowly added to the internal mixer, and the two are melted and blended for 10 minutes , take out the material and press it into shape;

[0033] (1.3) The materials taken were placed in a constant temperature and humidity environment before performance testing, maintaining a temperature of 25°C and a relative humidity of 60% for 48 hours.

[0034] Press the flame retardant composite material of step (1.3) gained into 100 × 100 ×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com