Passive type power vibration reduction floating slab track structure

A technology of dynamic vibration reduction and floating slabs, which is applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of reducing the rigidity of track structures, affecting the life of equipment, and failing to reduce the impact of vibration, so as to reduce low-frequency vibration components and eliminate Effects of Harmful Vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

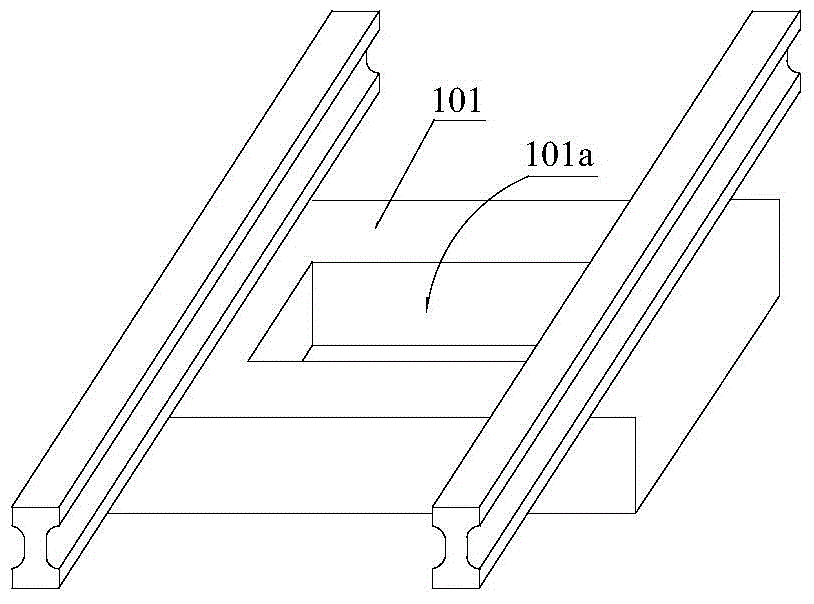

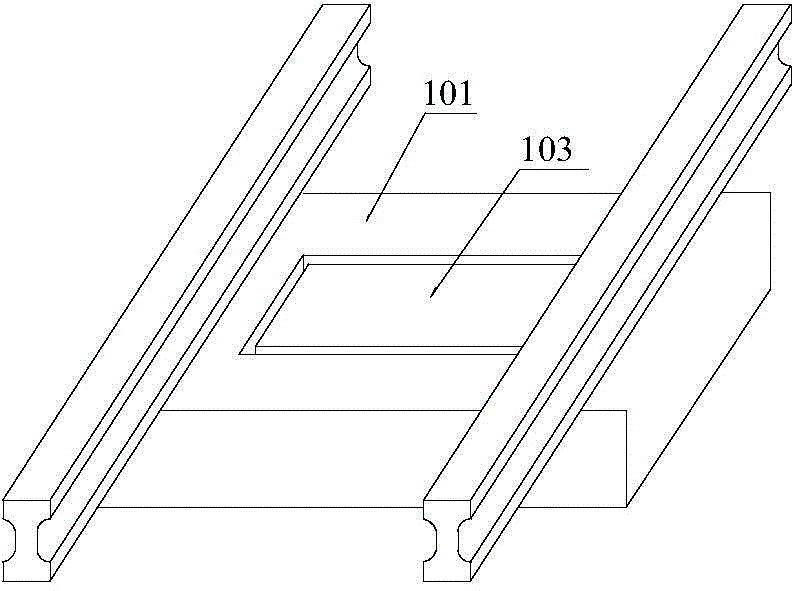

[0021] Embodiment 1: as figure 2 and image 3 As shown, an integral additional mass 103 is disposed in the frame space 101a of the floating plate main body 101, and an elastic connection is formed between the outer wall of the additional mass 103 and the side wall of the central cavity 101a through an elastic member.

Embodiment 2

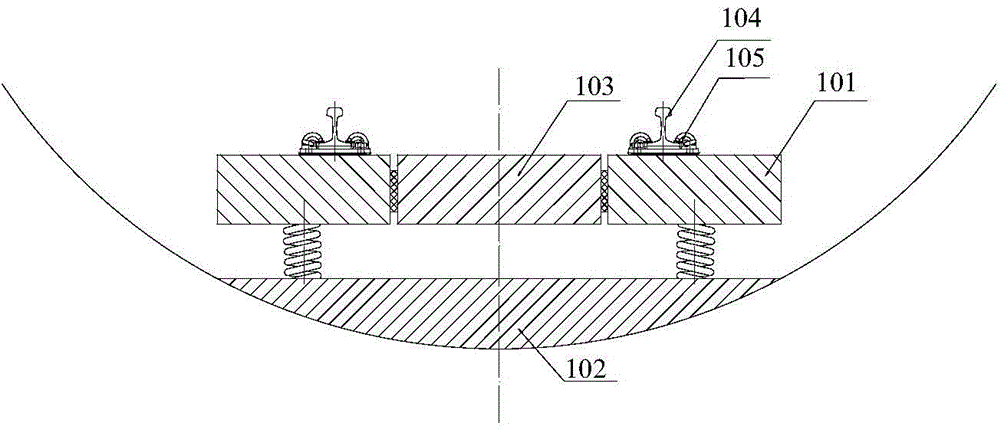

[0022] Embodiment 2: as Figure 4 As shown, an integral additional mass 103 is disposed in the frame space 101 a of the floating plate main body 101 , and an elastic connection is formed between the bottom wall of the additional mass 103 and the surface of the supporting foundation 102 through an elastic member.

Embodiment 3

[0023] Embodiment 3: as Figure 5 As shown, the additional mass block 103 composed of multiple unit blocks is arranged in the frame space 101a of the floating plate main body 101, and the bottom wall of each unit block and the surface of the supporting base 102 are elastically connected by elastic members. . The additional mass 103 can either be embedded in the support base 106 or attached to the surface of the support base 106 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com