vacuum cleaner floor brush

A vacuum cleaner and brush strip technology, which is applied in the field of vacuum cleaner floor brushes, can solve the problems of high mold cost for two pieces of ground brush pieces, long assembly man-hours, and misalignment of brush strips, etc., and achieves simple and convenient installation, low mold cost, and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

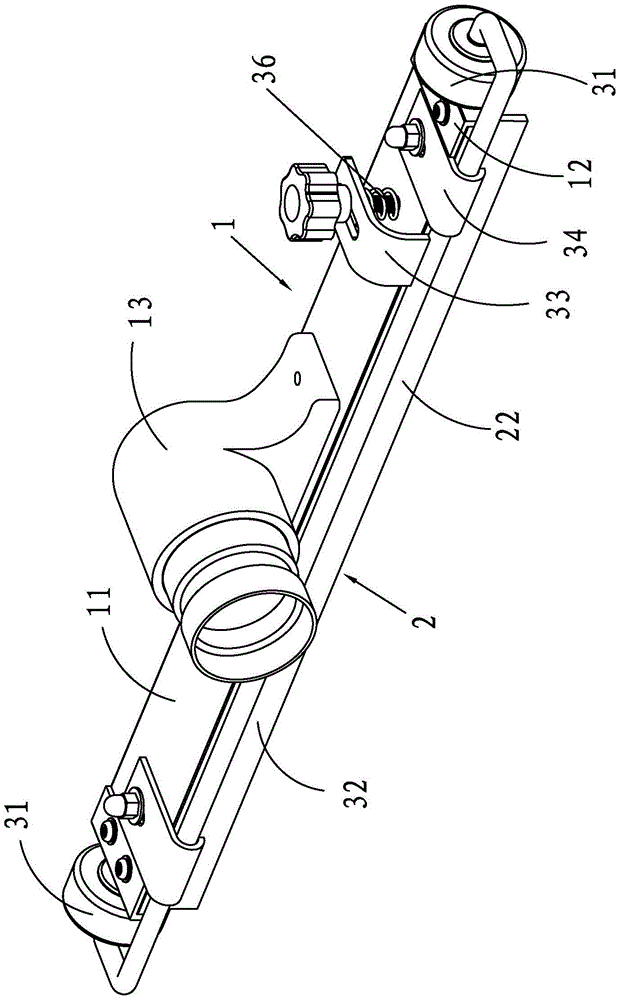

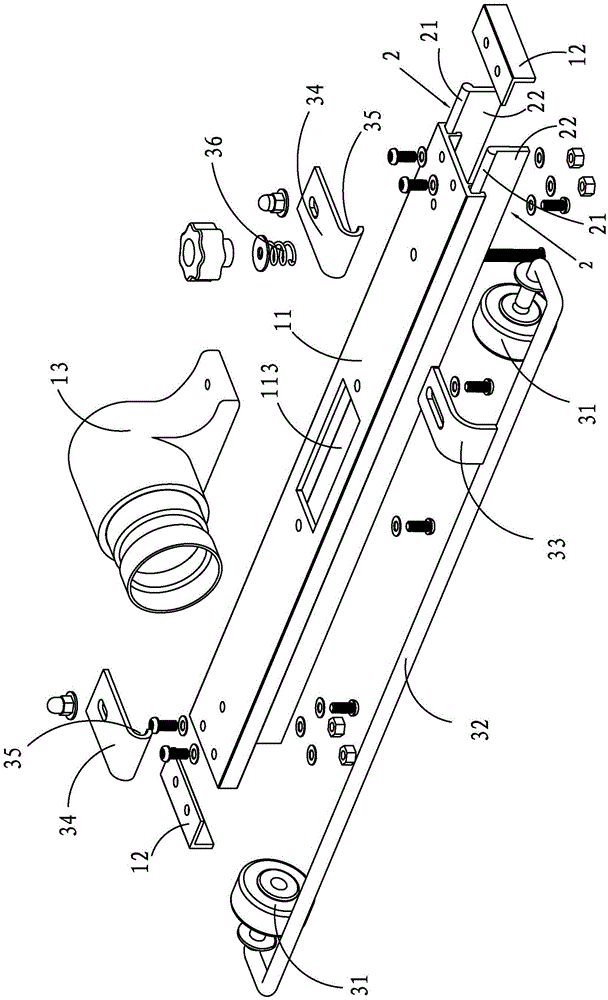

[0021] As shown in the accompanying drawings, a floor brush for a vacuum cleaner includes a floor brush holder 1 and two brush strips 2 respectively arranged on opposite sides of the floor brush holder 1 . Each brush bar 2 includes a brush bar body 22 and a brush bar mounting portion 21 located on one side of the brush bar body 22 . The brush strip body 22 is a brush or a rubber strip. Usually the brush strip body 22 is a hairbrush, and the brush strip installation part 21 is made of metal material, which is fixed on one side of the brush strip body 22; the brush strip body 22 is a rubber strip, and the brush strip installation part 21 is also a rubber strip, and made in one piece.

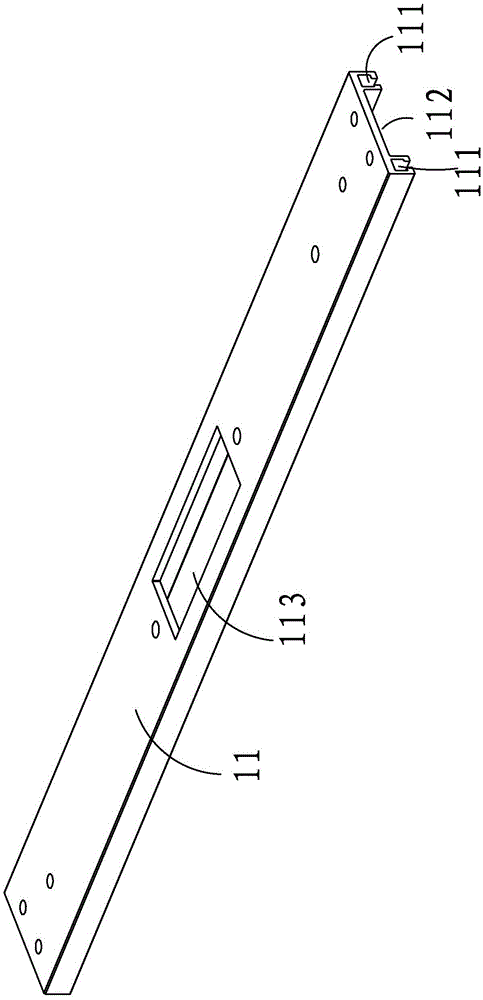

[0022] as attached figure 1 , 2 As shown, the floor brush holder 1 includes a strip-shaped floor brush holder body 11 and an end cover 12 for preventing the brush bar 2 from slipping or detaching from the floor brush holder body 11 . The end caps 12 are detachably fixed and installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com