Clamping feeding mechanism for lace lamps

A lamp clip and feeding technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low efficiency, large error, insufficient punching accuracy, etc., and achieve good clamping and feeding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

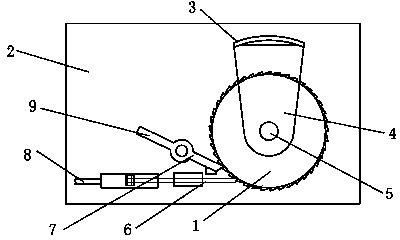

[0010] Combine below figure 1 Specific description embodiment:

[0011] A lace lamp clamping and feeding mechanism, characterized in that the lace lamp clamping and feeding mechanism includes a toothed plate 1, the toothed plate 1 is movably hinged on the bracket 2, and the toothed plate 1 is fixed with The lower splint 3, the lower splint 3 is provided with an upper splint 4, the upper splint 4 can be clamped with the lower splint 3 through the cylinder 5, and the support 2 is provided with a push rod 6 and a rotation stop rod 7. One end of the push rod 6 is in contact with the chainring 1, and the other end of the push rod 6 is connected with a linkage rod 8. Under the action of the linkage rod 8, the push rod 6 can make the teeth The disk 1 rotates, and the front end of the anti-rotation rod 7 is engaged with the toothed disk 1 .

[0012] Preferably, a wrench 9 is connected to the rear end of the anti-rotation rod 7 .

[0013] The lace lamp clipping and feeding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com