A piston-type rhombic structure optical fiber Bragg grating osmotic pressure sensor and its application method

The technology of a osmotic pressure sensor and a diamond-shaped structure is applied in the field of optoelectronic measuring devices to achieve the effects of easy operation, simple structure, strong anti-electromagnetic interference and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

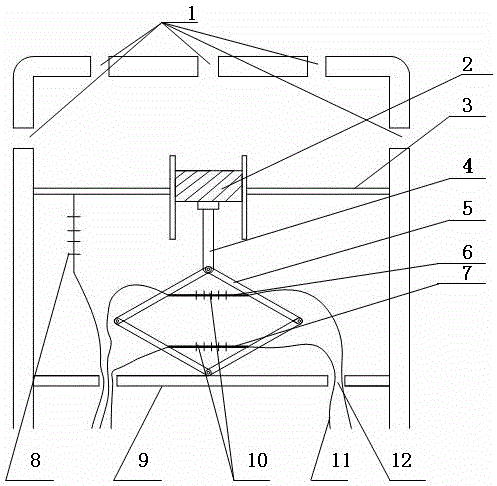

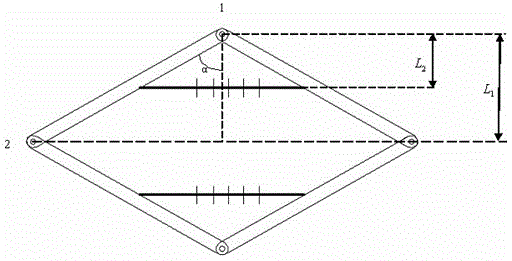

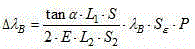

[0048] Embodiment 1: as Figure 1-2 As shown, a piston-type rhombic optical fiber Bragg grating pressure sensor includes a pressure inlet 1, a pressure-bearing piston 2, an upper support frame 3, a pressure guide rod 4, a diamond-shaped pressure transmission structure 5, an upper elastic steel sheet 6, a lower Elastic steel sheet 7, temperature-compensated fiber Bragg grating 8, lower support frame 9, fiber Bragg grating 10, lead-out optical fiber 11, and lead-out hole 12; the pressure inlet 1 is distributed in the pressure transmission chamber, the upper support frame 3, and the lower support frame 9 Welded on the shell, the middle of the upper support frame 3 is connected to the pressure-bearing piston 2, the bottom of the pressure-bearing piston 2 is connected to one end of the pressure guide rod 4, and the other end of the pressure guide rod 4 is connected to the upper end of the diamond-shaped pressure transmission structure 5, and the upper end The elastic steel sheet 6 ...

Embodiment 2

[0052] Embodiment 2: as Figure 1-2 As shown, a piston-type rhombic optical fiber Bragg grating pressure sensor includes a pressure inlet 1, a pressure-bearing piston 2, an upper support frame 3, a pressure guide rod 4, a diamond-shaped pressure transmission structure 5, an upper elastic steel sheet 6, a lower Elastic steel sheet 7, temperature-compensated fiber Bragg grating 8, lower support frame 9, fiber Bragg grating 10, lead-out optical fiber 11, and lead-out hole 12; the pressure inlet 1 is distributed in the pressure transmission chamber, the upper support frame 3, and the lower support frame 9 Welded on the shell, the middle of the upper support frame 3 is connected to the pressure-bearing piston 2, the bottom of the pressure-bearing piston 2 is connected to one end of the pressure guide rod 4, and the other end of the pressure guide rod 4 is connected to the upper end of the diamond-shaped pressure transmission structure 5, and the upper end The elastic steel sheet 6 ...

Embodiment 3

[0064] Embodiment 3: as Figure 1-2 As shown, a piston-type rhombic optical fiber Bragg grating pressure sensor includes a pressure inlet 1, a pressure-bearing piston 2, an upper support frame 3, a pressure guide rod 4, a diamond-shaped pressure transmission structure 5, an upper elastic steel sheet 6, a lower Elastic steel sheet 7, temperature-compensated fiber Bragg grating 8, lower support frame 9, fiber Bragg grating 10, lead-out optical fiber 11, and lead-out hole 12; the pressure inlet 1 is distributed in the pressure transmission chamber, the upper support frame 3, and the lower support frame 9 Welded on the shell, the middle of the upper support frame 3 is connected to the pressure-bearing piston 2, the bottom of the pressure-bearing piston 2 is connected to one end of the pressure guide rod 4, and the other end of the pressure guide rod 4 is connected to the upper end of the diamond-shaped pressure transmission structure 5, and the upper end The elastic steel sheet 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com