Temperature self-compensation fiber grating large-strain sensor

A fiber grating and sensor technology, which is applied in the field of wavelength modulation optical fiber sensor, can solve the problems such as difficult to eliminate the influence of temperature, achieve the effect of saving bandwidth, solving the problem of temperature-strain cross-sensitivity, and realizing large-strain measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

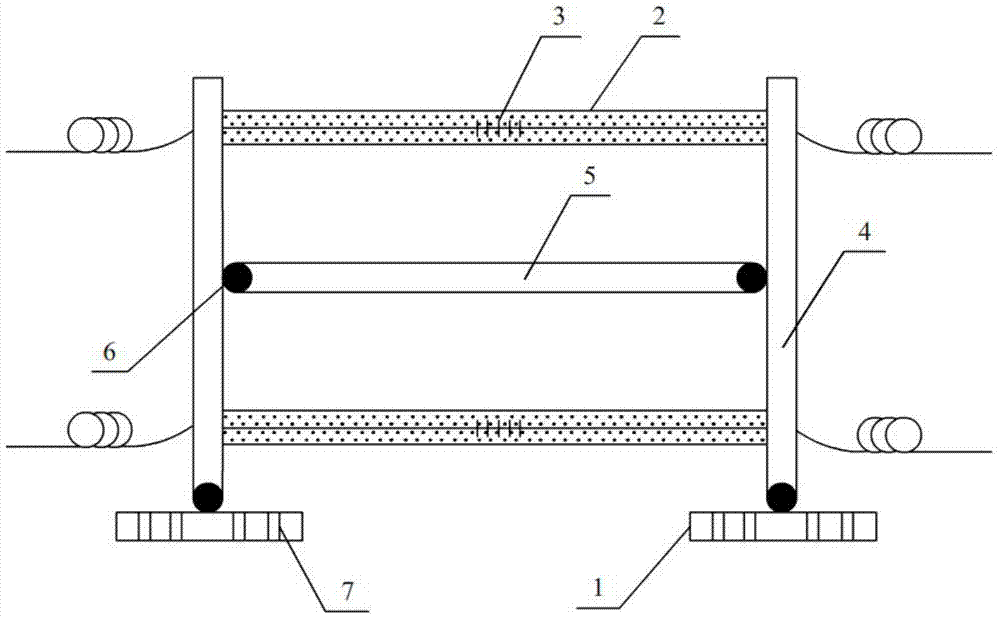

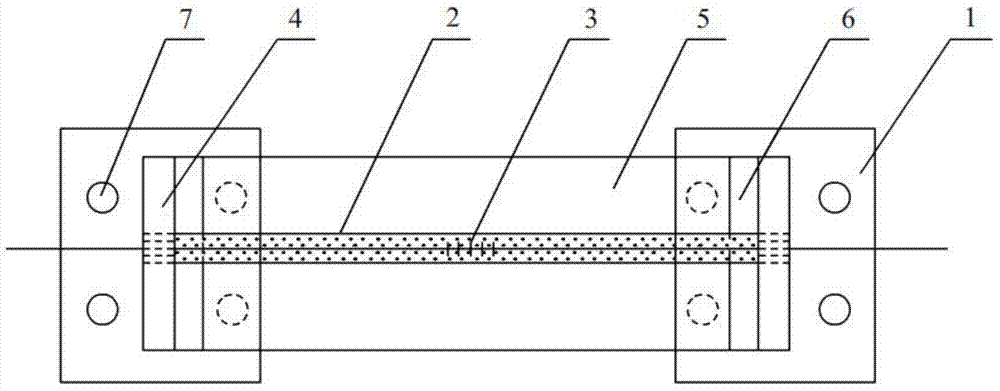

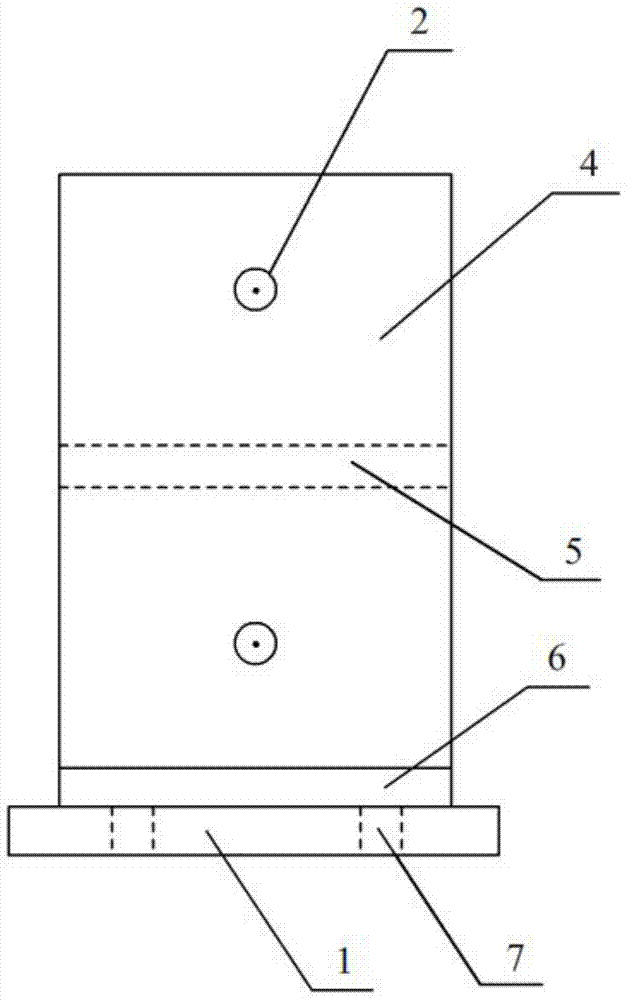

[0025] Such as figure 1 , 2 , 3, the sensor of the present invention includes a base 1, two capillary steel pipes 2, two fiber gratings 3, two vertical support plates 4, and a horizontal support plate 5; the base is a rectangular plate structure, in The top surface of the base is connected to the vertical support plate through the rotating connection shaft 6, and two capillary steel pipes are fixed parallel up and down between the two vertical support plates, and the two capillary steel pipes are horizontally parallel and vertically fixed to the vertical support plate , there is a horizontal support plate between the two capillary steel pipes, the horizontal support plate is in a horizontal state and the two ends are movably connected with the two vertical support plates through the rotating connection shaft; each capillary steel pipe is rigid after applying prestress The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com