A differential lever structure fiber bragg grating liquid level sensor and using method thereof

A liquid level sensor, differential technology, applied in the field of differential lever structure optical fiber Bragg grating liquid level sensor, to achieve the effect of easy operation, simple structure, strong anti-electromagnetic interference ability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

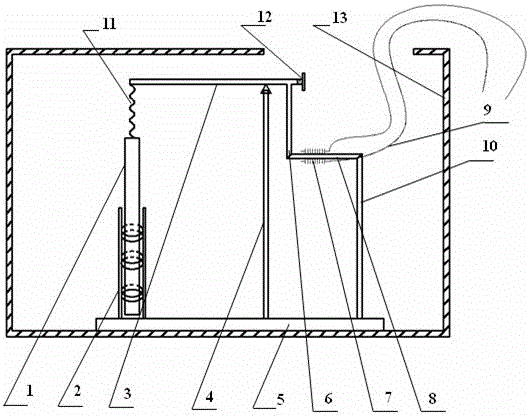

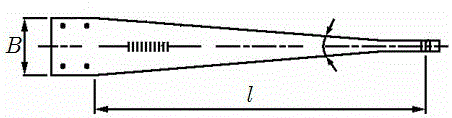

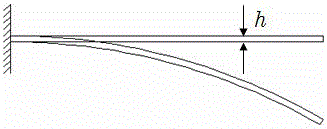

[0045] Embodiment 1: as Figure 1-3As shown, a differential lever structure optical fiber Bragg grating liquid level sensor includes a hollow buoyancy plastic rod 1, a position fixing ring sleeve 2, a lever 3, a lever support rod 4, a fixed base 5, a pressure transmission rod 6, and an optical fiber Bragg grating 7. Equal strength cantilever beam 8, leading optical fiber 9, cantilever beam support rod 10, force transmission spring 11, container wall 13; wherein the fixed base 5 is placed at the bottom of the container, the position fixing ring sleeve 2, the lever support rod 4 and the cantilever beam support The rod 10 is welded on the fixed base 5, the hollow buoyancy plastic rod 1 is placed in the position fixing ring sleeve 2, the top of the hollow buoyancy plastic rod 1 is connected to the force transmission spring 11, and the other end of the force transmission spring 11 is connected to the left end of the lever 3, and the lever The support rod 4 is connected with the 3 f...

Embodiment 2

[0050] Embodiment 2: as Figure 1-3 As shown, a differential lever structure optical fiber Bragg grating liquid level sensor includes a hollow buoyancy plastic rod 1, a position fixing ring sleeve 2, a lever 3, a lever support rod 4, a fixed base 5, a pressure transmission rod 6, and an optical fiber Bragg grating 7. Equal strength cantilever beam 8, leading optical fiber 9, cantilever beam support rod 10, force transmission spring 11, container wall 13; wherein the fixed base 5 is placed at the bottom of the container, the position fixing ring sleeve 2, the lever support rod 4 and the cantilever beam support The rod 10 is welded on the fixed base 5, the hollow buoyancy plastic rod 1 is placed in the position fixing ring sleeve 2, the top of the hollow buoyancy plastic rod 1 is connected to the force transmission spring 11, and the other end of the force transmission spring 11 is connected to the left end of the lever 3, and the lever The support rod 4 is connected with the 3 ...

Embodiment 3

[0056] Embodiment 3: as Figure 1-3 As shown, a differential lever structure optical fiber Bragg grating liquid level sensor includes a hollow buoyancy plastic rod 1, a position fixing ring sleeve 2, a lever 3, a lever support rod 4, a fixed base 5, a pressure transmission rod 6, and an optical fiber Bragg grating 7. Equal strength cantilever beam 8, leading optical fiber 9, cantilever beam support rod 10, force transmission spring 11, container wall 13; wherein the fixed base 5 is placed at the bottom of the container, the position fixing ring sleeve 2, the lever support rod 4 and the cantilever beam support The rod 10 is welded on the fixed base 5, the hollow buoyancy plastic rod 1 is placed in the position fixing ring sleeve 2, the top of the hollow buoyancy plastic rod 1 is connected to the force transmission spring 11, and the other end of the force transmission spring 11 is connected to the left end of the lever 3, and the lever The support rod 4 is connected with the 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com