Test method and device for bending stiffness in high and low temperature environment

A bending stiffness, testing device technology, applied in measuring devices, using stable bending force to test material strength, using optical devices, etc., can solve the problem that the laser transmitter cannot be located on the component and follows the three-dimensional displacement of a certain point. , to achieve the effect of good real-time performance, strong reliability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

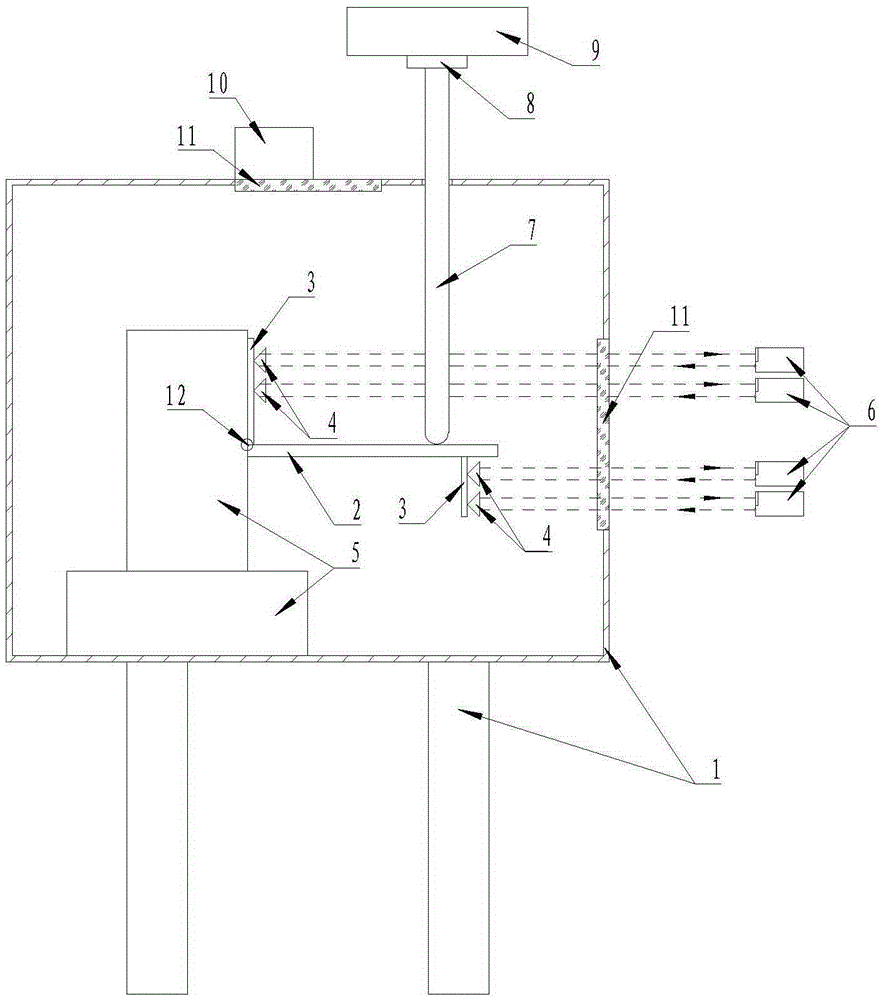

[0028] With reference to the accompanying drawings, a bending stiffness test method and device in a high and low temperature environment, including a high-resolution camera 10, a high-rigidity rod 7, a laser measurement group, a force sensor 8, a lifting device 9, and the like.

[0029] The DUT 2 and its mounting base 5 are placed in the high and low temperature box 1, one end of the high rigidity rod 7 is fixedly connected with the lifting device 9, and the other end of the high rigidity rod 7 is a smooth spherical surface and Acting vertically on the tested object 2, a force sensor 8 is installed between the high rigidity rod 7 and the lifting device 9.

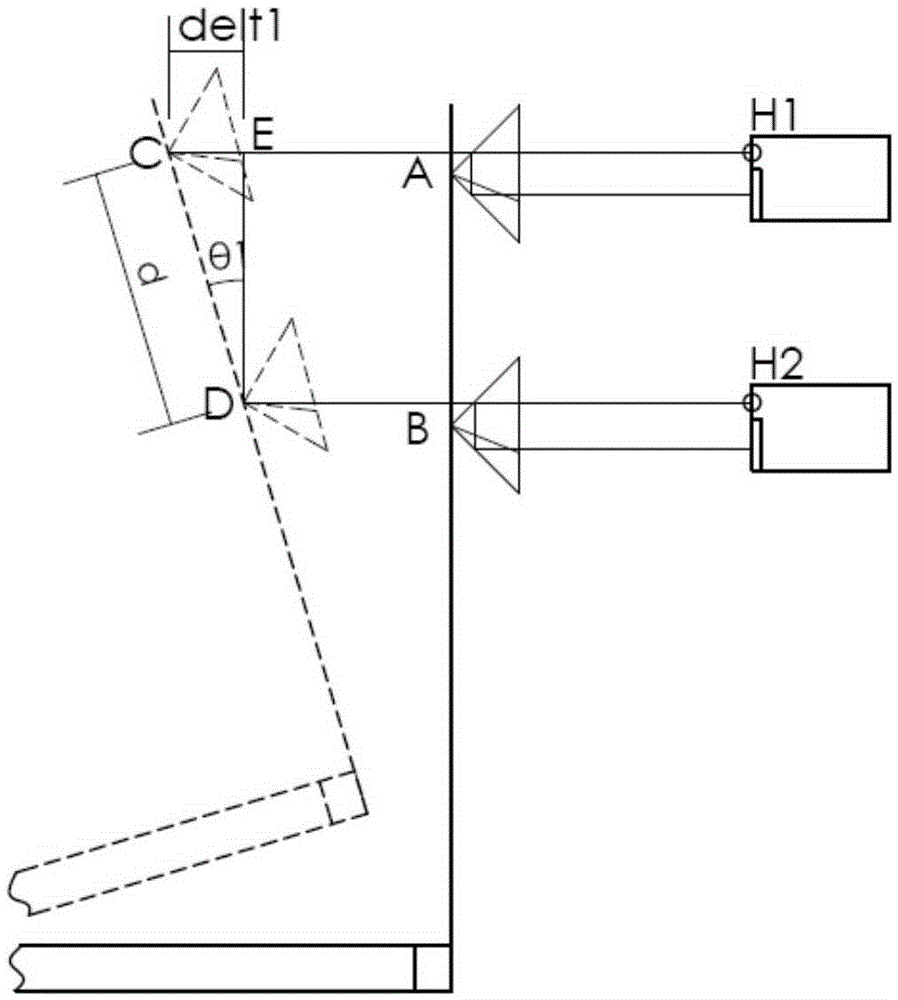

[0030] The high-resolution camera 10 is fixed on the observation window 11 at the top of the high-low temperature box 1, and a calibration point 12 is set at the root of the connection between the tested part 2 and the mounting base 5, and the distance between the calibration point 12 and the high-rigidity rod 7 is fixed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com