Flexural rigidity testing device

A testing device, stiffness technology, applied in the direction of measuring device, using optical device, applying stable tension/pressure to test material strength, etc., can solve problems such as following a certain point's three-dimensional displacement, laser emitter cannot be located on the component, etc. It achieves the effects of good real-time performance, accurate measurement of deflection angle deformation, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

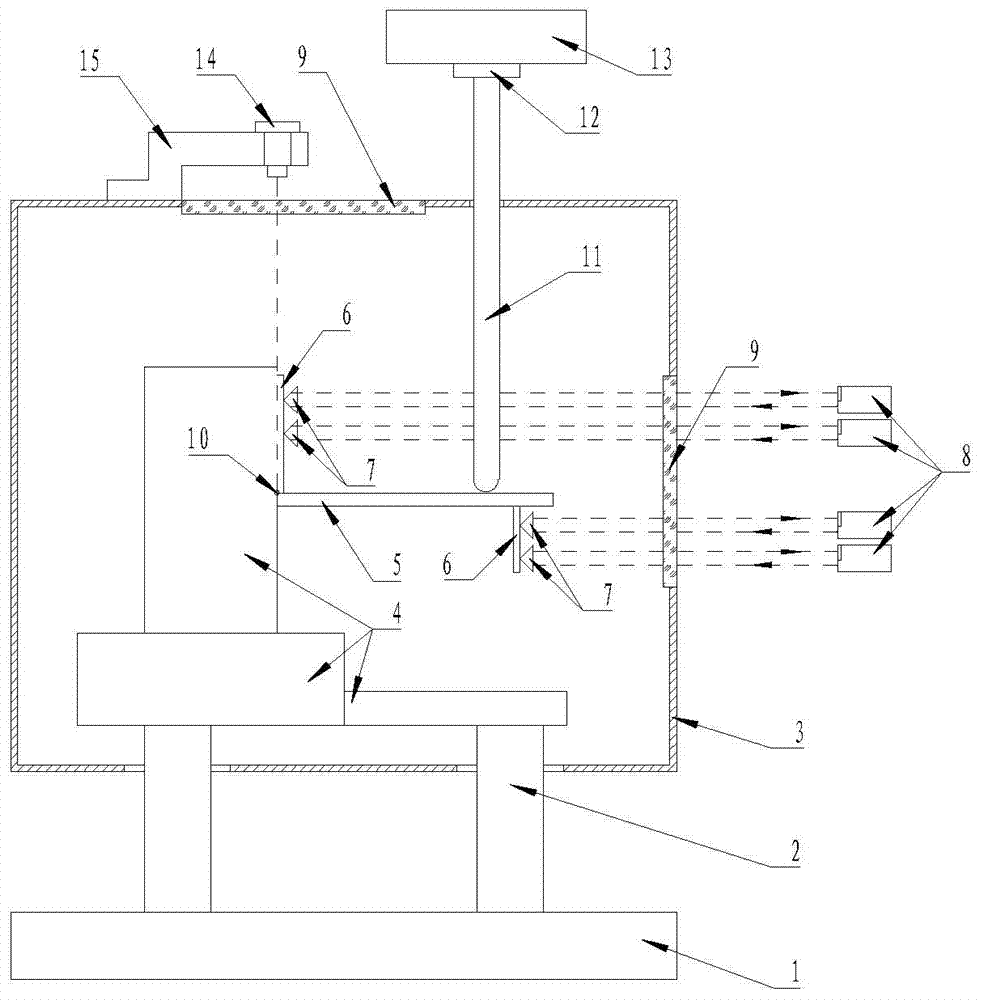

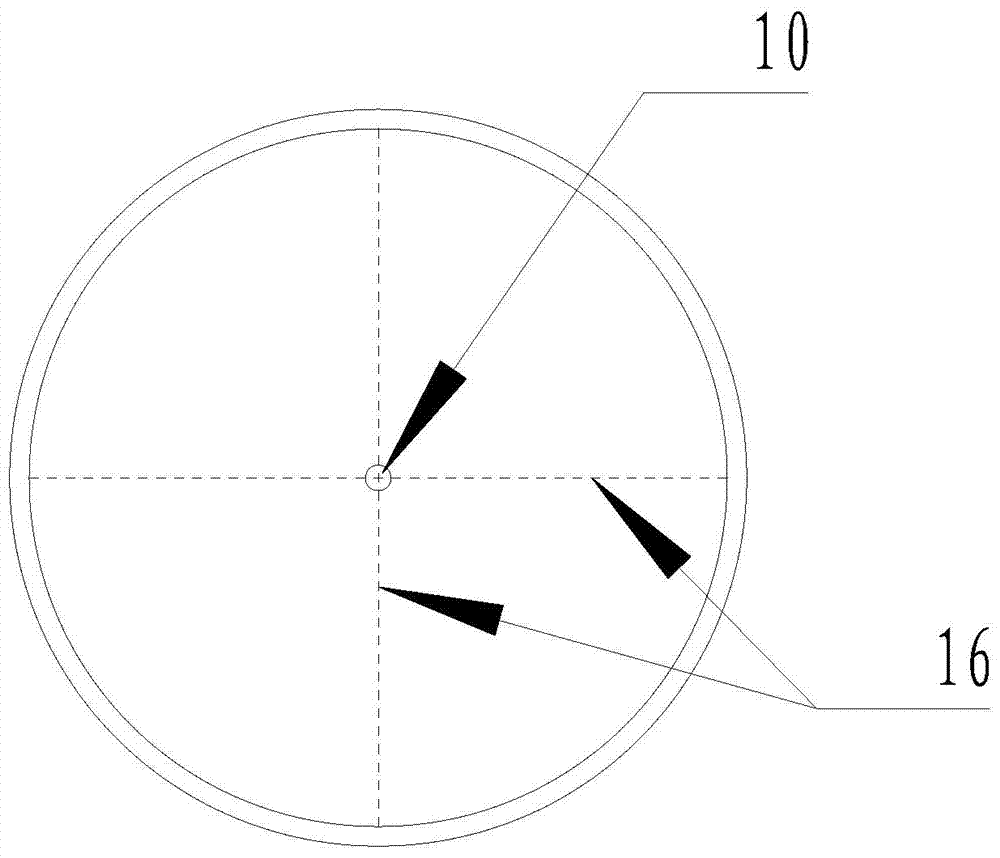

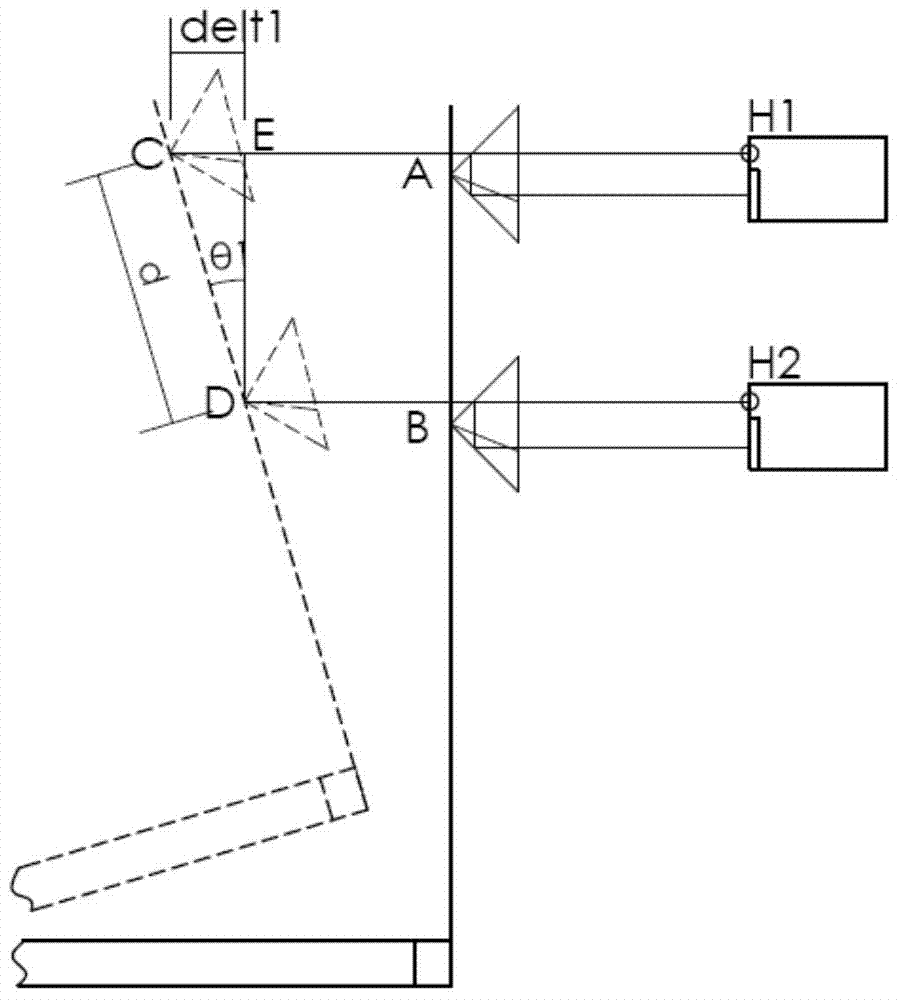

[0031] combine Figure 1 to Figure 3 , a bending stiffness testing device, the testing device includes an optical lens 14, a high rigidity rod 11, a lifting device 13, a two-dimensional mobile platform 1, a laser measurement group, a high and low temperature box 3, and the like. The two-dimensional mobile platform 1 is located below the high and low temperature box 3, the lifting device 13 is located above the high and low temperature box 3, the top and sides of the high and low temperature box 3 are provided with observation windows 9, and the optical lens 14 is installed Seat 15 is fixed on the observation window 9 on the high and low temperature box 3 tops.

[0032] A bracket 2 is installed on the two-dimensional mobile platform 1, and the bracket 2 passes through the through hole at the bottom of the high and low temperature box 3 into the high and low temperature box. The DUT 5 is installed on the mounting base 4 .

[0033] The lower end of the high rigidity rod 11 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com