Modular dual nozzle ink stack

A dual-nozzle, modular technology, used in printing and other directions, can solve problems such as affecting product installation accuracy and performance, lack of regularity, and complex installation and adjustment processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

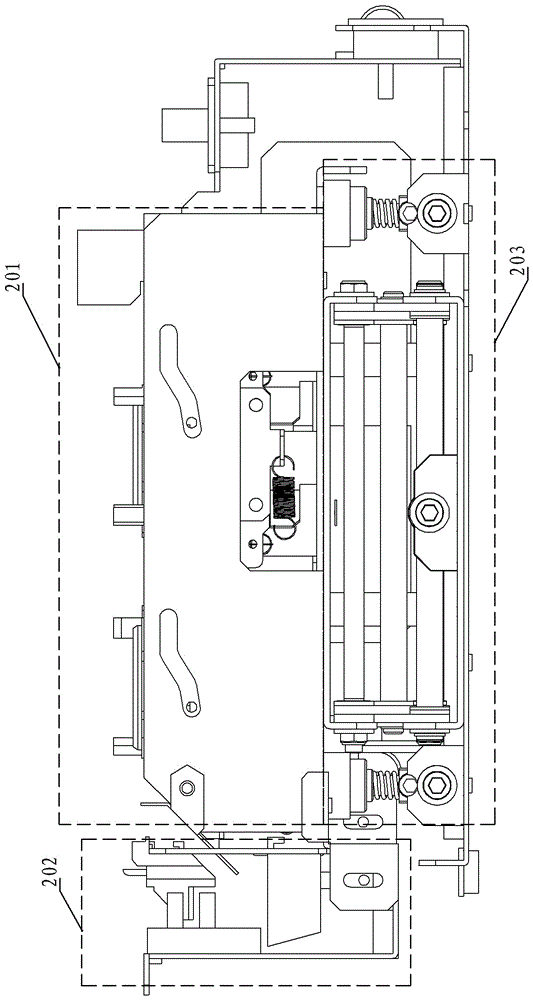

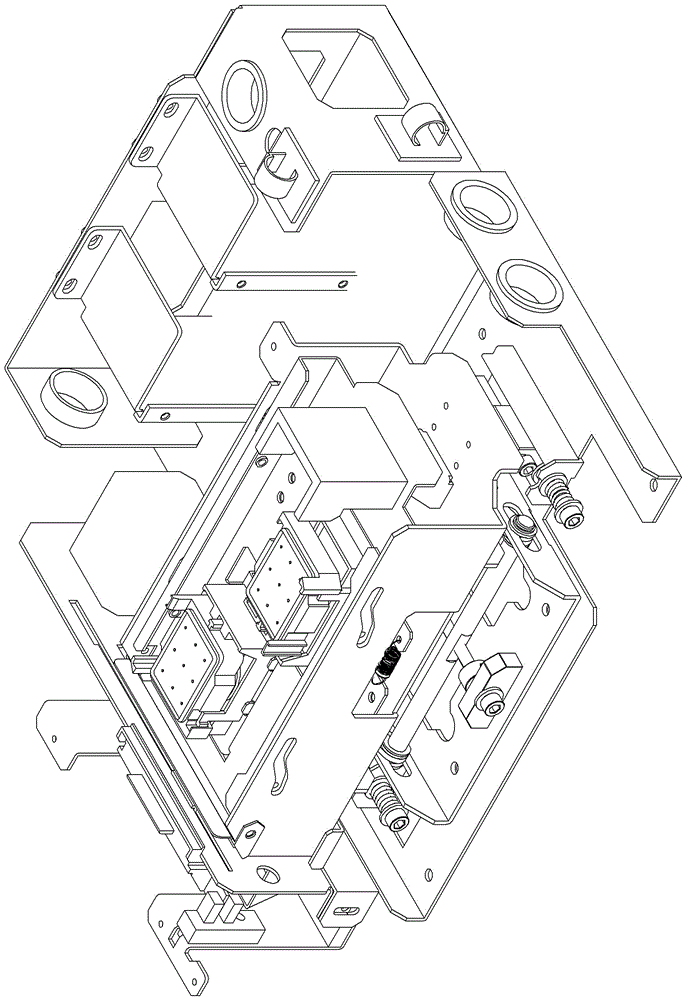

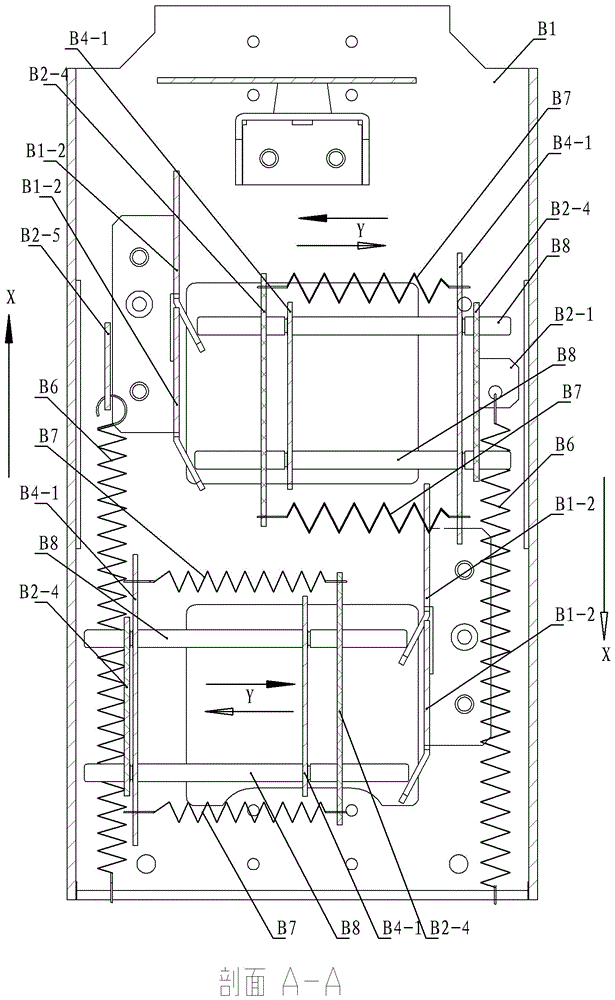

[0042] Example: see Figure 1-4 , a modular double nozzle ink stack in the figure, including a base, an alignment adjustment module, a two-way motion alignment module, and a scraping ink module. The ink scraping module is installed at one end of the base, and the alignment adjustment module Installed in the middle of the base, the two-way motion alignment module is installed on the upper part of the alignment adjustment module; the scraping module includes a bracket connected to the base, an ink pool installed in the middle of the bracket, a scraping plate on the upper part of the bracket, A sponge is arranged on the bottom plate of the bracket at the lower part of the ink pool; the bracket is provided with a chute along the length direction, and the scraper is installed in the chute and can slide along the chute. The alignment adjustment module includes an elevating mechanism and a horizontal adjustment mechanism at the lower part of the ink stack housing and is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com