Powder tank

A powder material tank and powder material technology, applied in the field of powder material tank, can solve problems such as hidden safety hazards, tearing or opening of the powder material tank, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

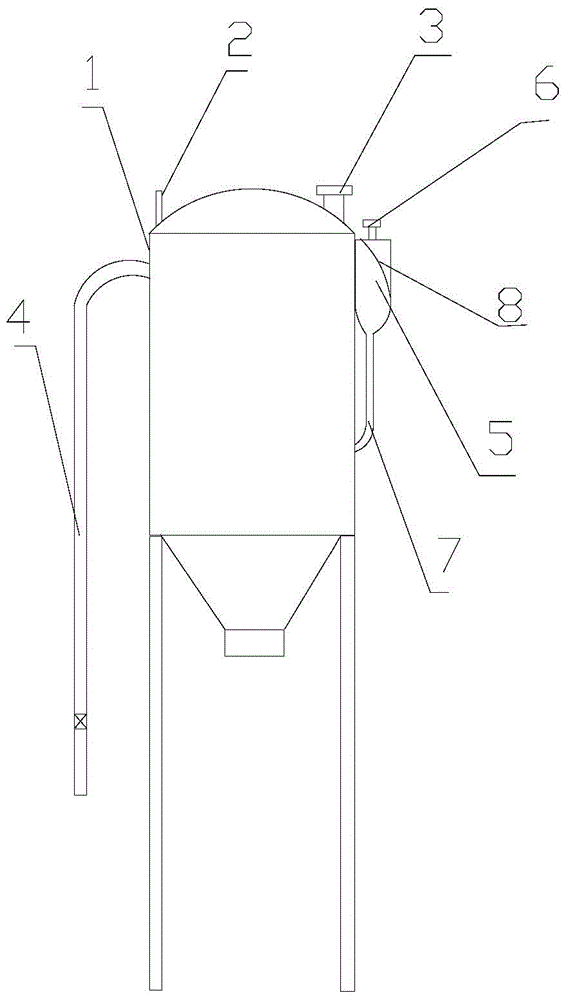

[0014] see figure 1 , a powder tank, comprising a silo 1, a feed pipe 4, a safety valve 2 and a dust collector 3; the silo 1 forms a powder storage chamber, and the feed pipe 4 communicates with the powder storage chamber, The dust collector 3 is installed between the powder storage cavity and the outside; the silo 1 is provided with a buffer box 5, the buffer box 5 has an inlet and an outlet, and the inlet and the powder storage cavity The upper part communicates, the outlet communicates with the lower part of the powder storage chamber through a buffer pipe 7, and the buffer box 5 is provided with a dust collector 6.

[0015] By providing a buffer box 5 and a dust collector 6 on the buffer box 5, the powder tank has double filtering and decompression functions, which effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com