A method for harmless treatment of arsenic-containing waste with coexistence of multiple metals

A harmless treatment, multi-metal technology, applied in the direction of process efficiency improvement, etc., can solve the problems of failing to meet the national harmless standard, unable to recycle valuable metals, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

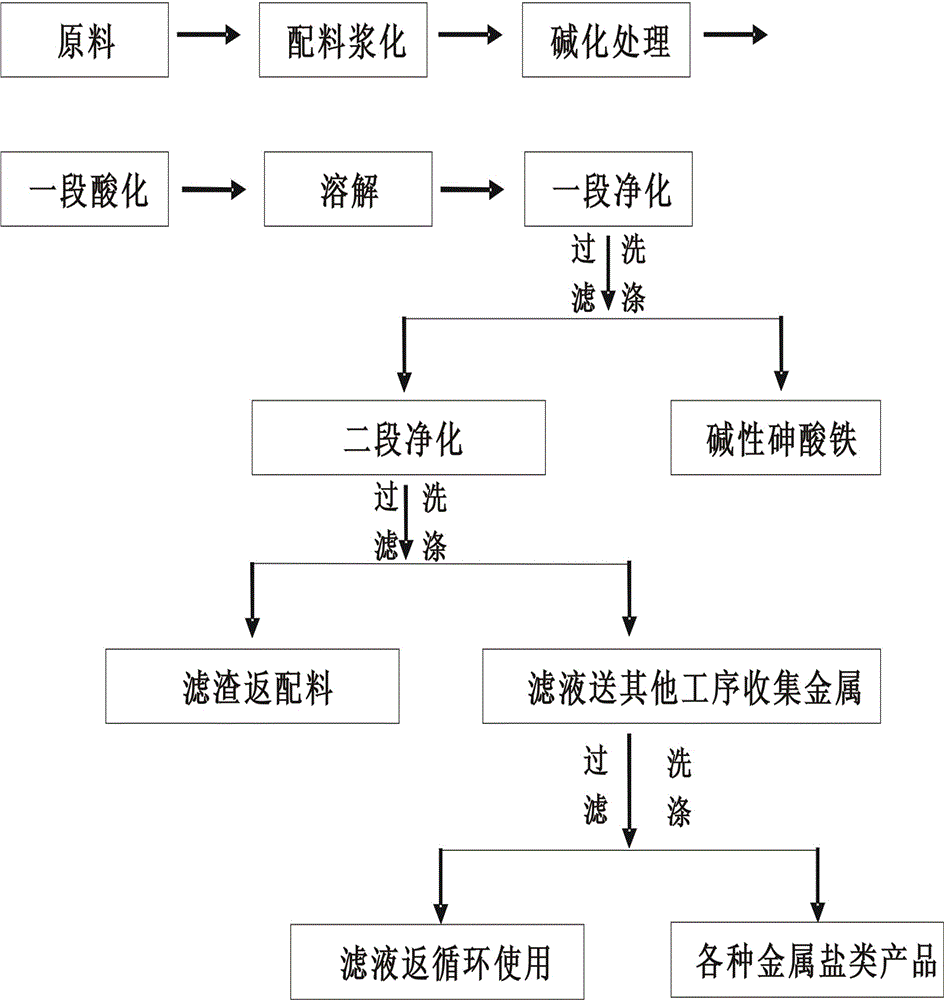

[0023] The flow chart of the harmless treatment method for arsenic-containing waste coexisting with multiple metals is as follows figure 1 As shown, specifically:

[0024] A method for harmless treatment of arsenic-containing waste coexisting with multiple metals comprises the following steps:

[0025] (1) Add Fe salt to HW48, HW24, and HW17 arsenic-containing wastes so that Fe:As=3-4:1 in the arsenic-containing wastes; Mix parts by weight to prepare a mixed slurry, then add sodium hydroxide to the mixed slurry, add sodium hypochlorite when the pH of the mixed slurry is greater than or equal to 13, and stop adding sodium hypochlorite until the pH value of the mixed slurry is recovered and maintained at a pH greater than or equal to 13; dilute Sulfuric acid is prepared by 1 part 98% sulfuric acid and 2 parts water.

[0026] (2) When the pH value of the mixed slurry is re-stabilized at pH ≥ 13, adjust the mixed slurry with dilute sulfuric acid to make the mixed slurry pH 6-8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com