Method for determining plastic volume shrinkage of cement paste

A volume shrinkage rate and determination method technology, applied in the direction of material inspection products, etc., can solve the problems of inability to simulate the bottom temperature and pressure conditions, inability to meet the research needs of anti-gas channeling, inability to accurately measure the shrinkage and expansion of cement slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Further illustrate the present invention below in conjunction with accompanying drawing.

[0093] A method for determining plastic volume shrinkage of cement slurry, comprising the following steps in sequence:

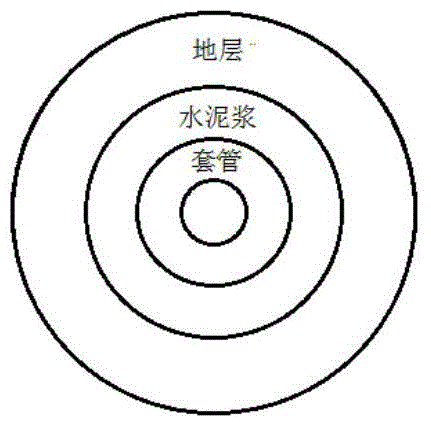

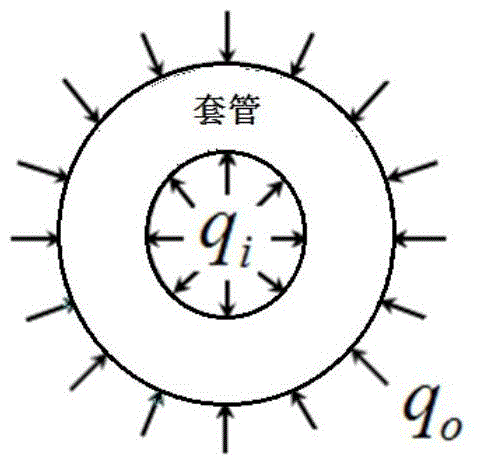

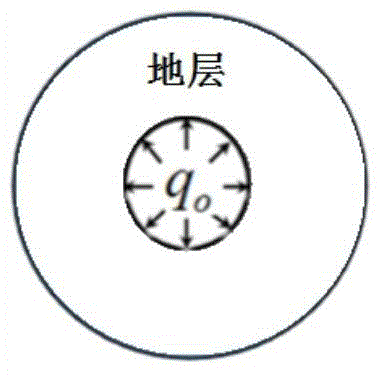

[0094] (1) Obtain relevant size parameters of casing and wellbore: casing inner radius r i =78.55mm, outer radius r o =88.9mm (d i =177.8mm), borehole radius r w =107.95mm (d w =215.9mm);

[0095] (2) Obtain the relevant mechanical parameters of casing and formation rock: elastic modulus E of casing case =206.9GPa, Poisson's ratio μ case =0.3, the elastic modulus E of formation rock f =13.84GPa, Poisson's ratio μ f =0.287;

[0096] (3) Determine the relevant working condition parameters of oil and gas wells: including well depth H=5085m, formation pressure coefficient P T =0.0225MPa / m, electric logging temperature T=122℃, drilling fluid density ρ d =2.30g / cm 3 , cement slurry density ρ s =2.35g / cm 3 , water-solid ratio w / s=0.263;

[0097] (4) Comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com