A kind of processing equipment and method of plastic pipe connecting piece

A plastic pipe and processing equipment technology, applied in the field of processing equipment for plastic pipe interconnectors, can solve the problems of high mold cost and material cost, time-consuming, complicated process, etc., and achieve cost saving, high production efficiency, flexible and convenient combination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

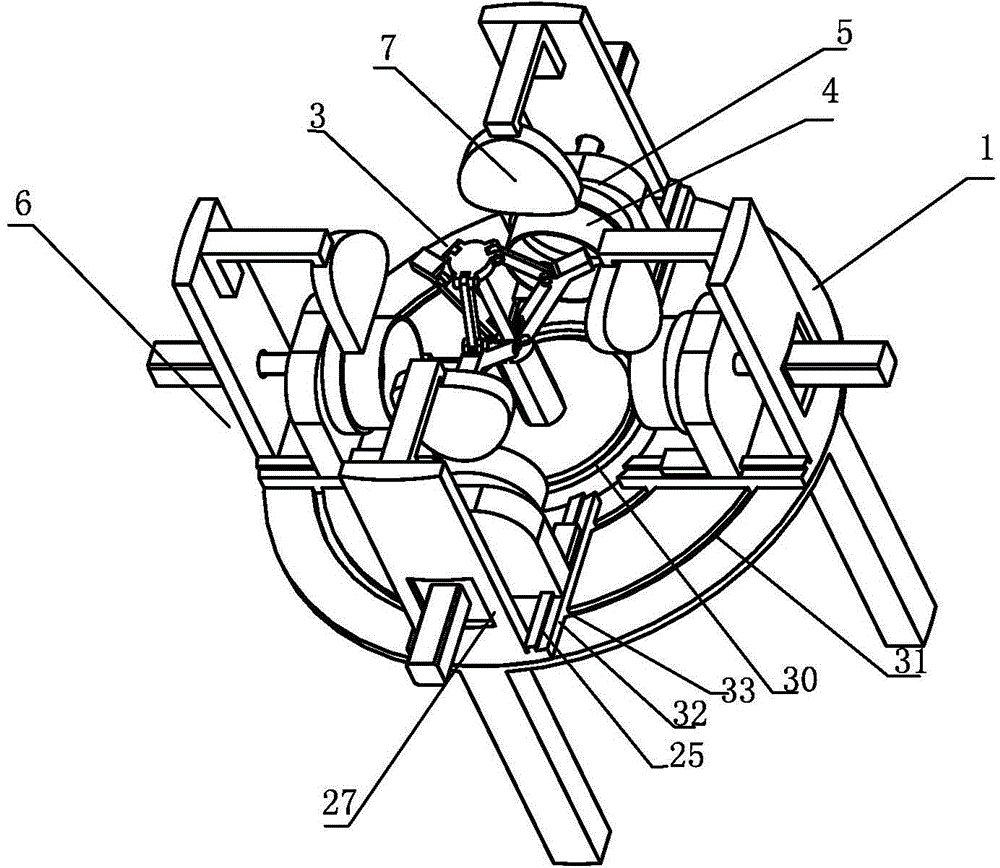

[0030] A kind of processing equipment of plastic pipe connecting parts, comprising an operation platform 1, a first clamp 3 which can fix or release the main pipe 2 is arranged in the center of the operation platform 1, and a plurality of fixable or release branch pipes 4 located on the periphery of the first clamp 3 The second clamp 5 , the drive mechanism 6 for moving the second clamp 5 radially along the center of the operating platform 1 , and the heating component 7 that can move up and down.

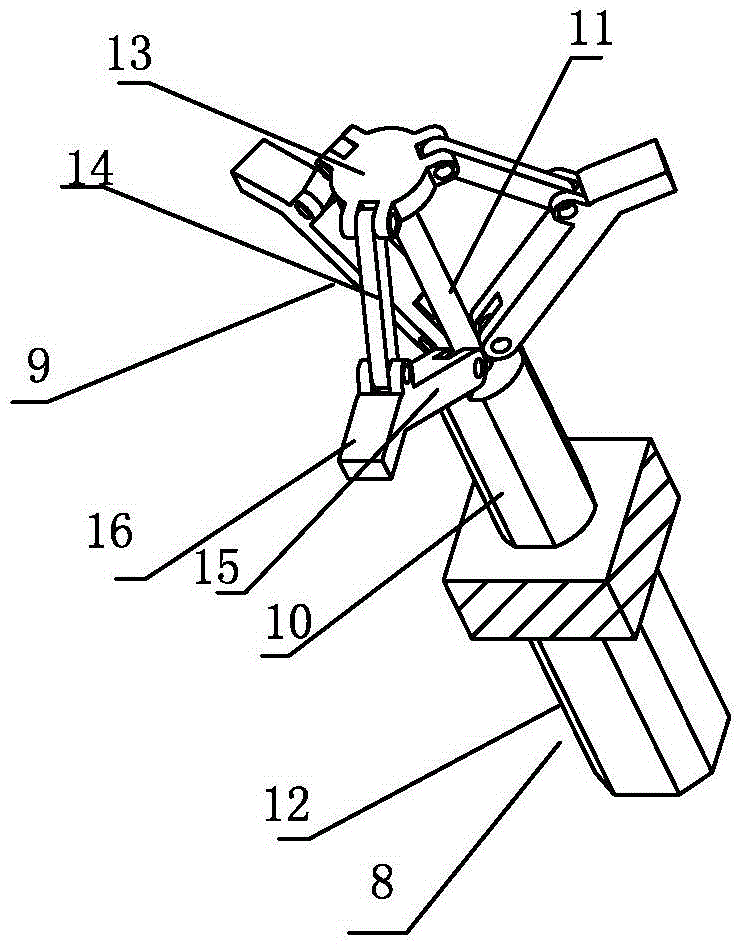

[0031] The first fixture 3 includes a first cylinder 8, a multi-catch assembly 9 and a fixed frame 10, the first cylinder 8 includes a first cylinder connecting rod 11 and a first cylinder body 12, and the multi-catch assembly 9 includes an upper platform 13 and a plurality of diagonal tie rods Assemblies, the diagonal tie rod assembly includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com