Tire tread made from multi cap compounds

一种橡胶化合物、胎面的技术,应用在轮胎胎面/胎面花纹、特殊轮胎、车辆部件等方向,能够解决轮胎湿道路性能受限、低防滑深度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

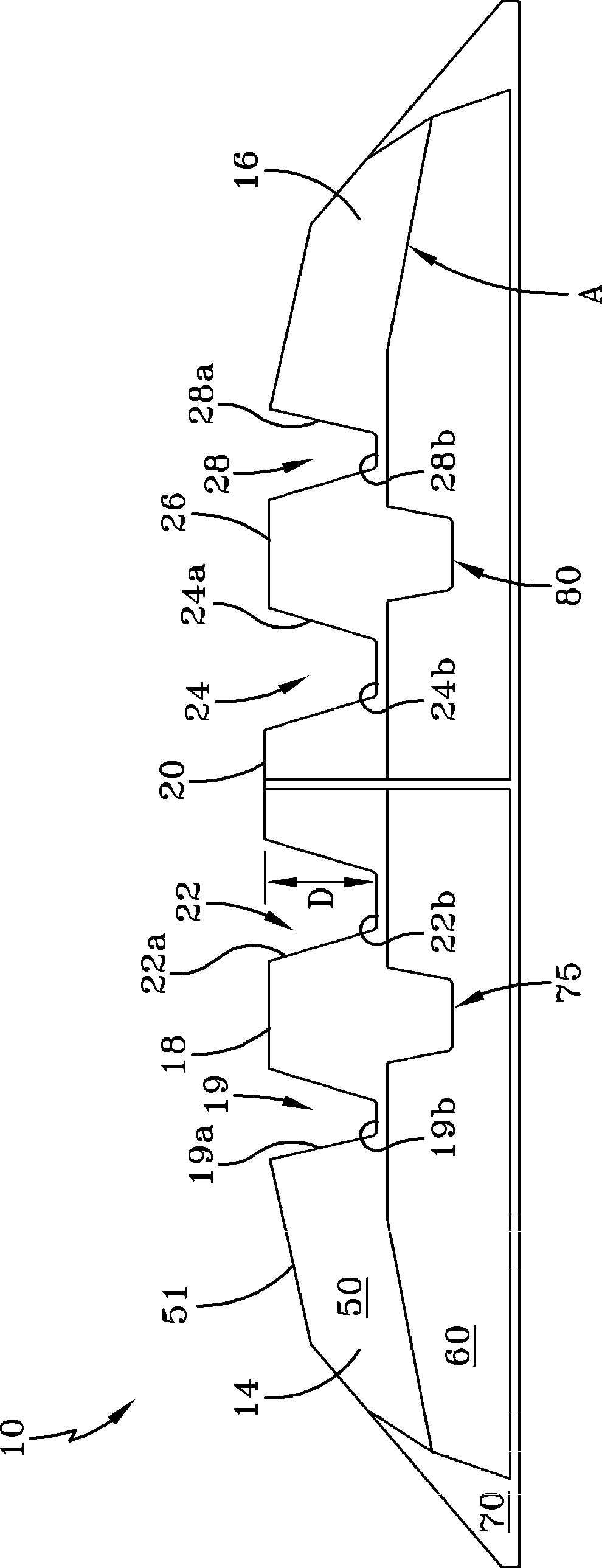

[0028] exist figure 1 A cross-sectional view of a cured pneumatic tire tread layout 10 is shown in . Pneumatic tires may be formed from typical tire components known to those skilled in the art, such as, but not limited to, inner liner (not shown), annular beads (not shown), sidewalls (not shown), apex ( not shown), carcass (not shown) and belt assembly (not shown). The tire tread 10 has first and second shoulder blocks 14, 16 that form the shoulder region of the tire. The tire tread 10 may also include at least two ribs 18 , 20 , preferably three ribs 18 , 20 , 26 . The invention is not limited to ribs, and may alternatively be tread blocks, preferably circumferentially aligned tread blocks. Ribs 18, 26 are separated from shoulder blocks 14, 16 by grooves 19, 28, respectively. The ribs 18 , 20 , 26 are separated from one another by grooves 22 , 24 . The grooves 19, 22, 24, 28 have a defined depth D and preferably have inclined side walls 19a, 22a, 24a, 28a and flat floor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com