Filling valve

A filling valve and filling technology, which is used in packaging, bottle filling, liquid bottling, etc., can solve the problems of low quality of filling products, broken and broken valve bodies, aging of pipe and valve seals, etc., so as to shorten the filling time. Filling cycle, improve the quality of filling products, improve the effect of filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below:

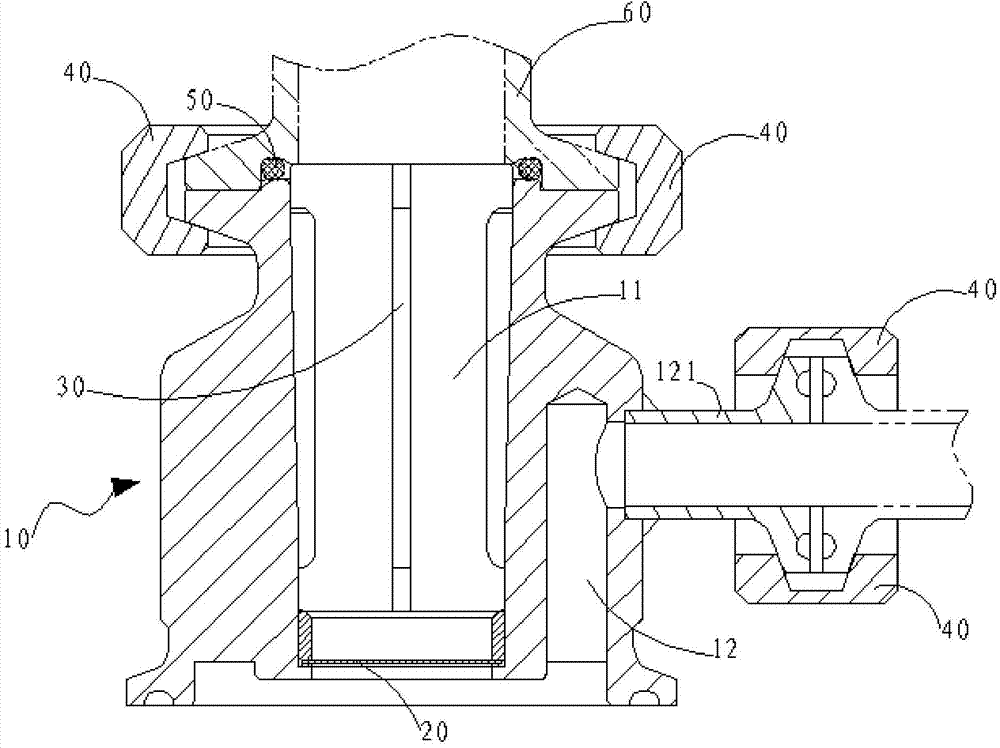

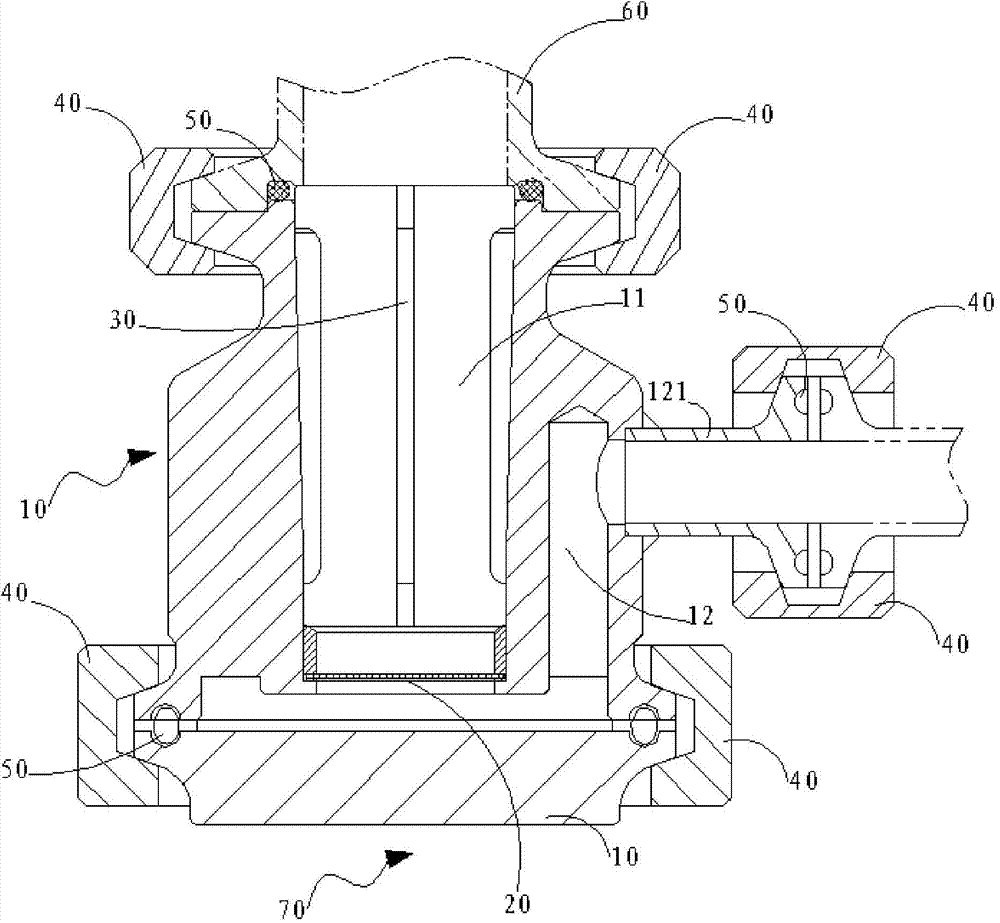

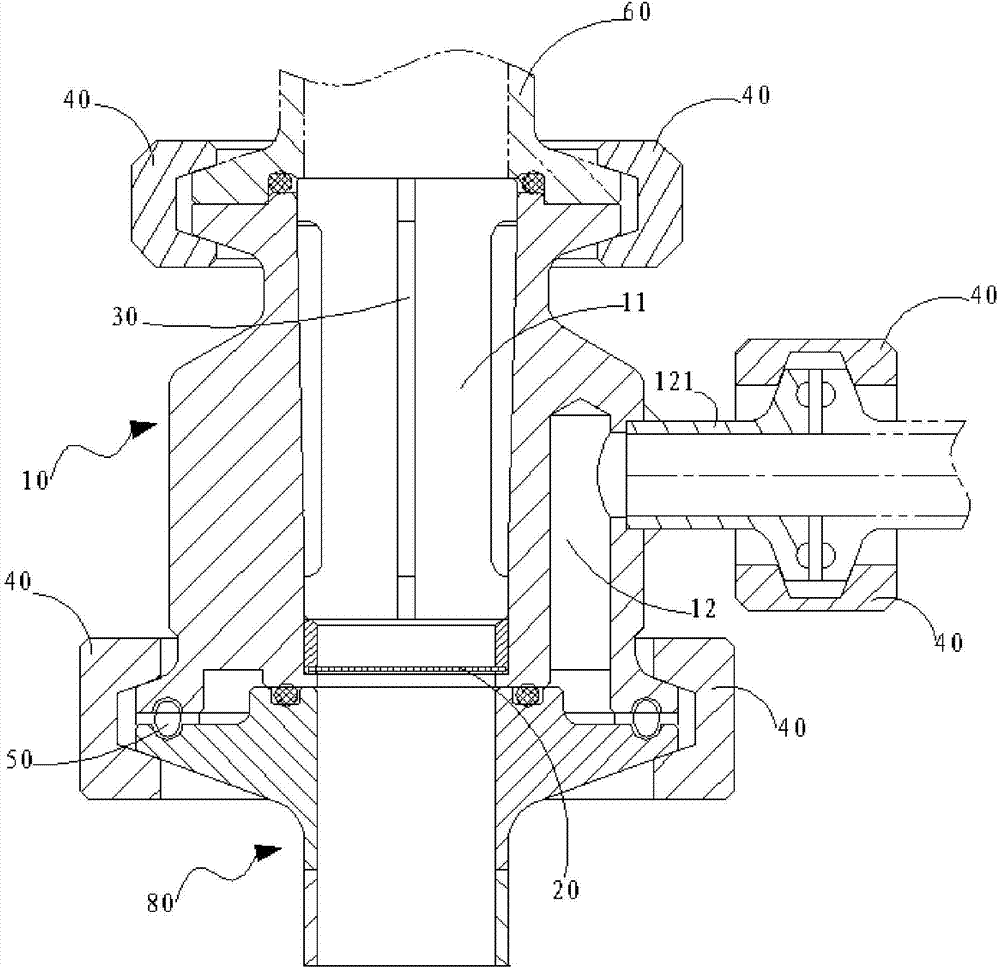

[0025] Such as figure 1 As shown, a filling valve includes a filling valve body 10, the filling valve body 10 is provided with a filling channel 11, and a filter screen 20 for locking water and filtering is arranged in the filling channel 11. The water-locking function of the filter screen 20 is to use the surface tension of the filling liquid to overcome the gravity of the filling liquid and stay in the filling pipe. The liquid is adsorbed at the outlet, so as to achieve the effect of sealing water. The filter screen 20 with the water-locking function has become the prior art, and the present invention will not repeat it here. It is only necessary to select and use filter screens 20 with different apertures according to filling liquids with different viscosities.

[0026] By adding a filter screen 20 for water locking and filtering on the filling channel 11 in the filling valve body 10, when filli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap