Cemented filling material

A technology of filling and filling slurry, which is applied in the field of mine filling materials, can solve the problems that the curing strength cannot meet the mining requirements, the filling cost increases, and it is difficult to meet the requirements, etc., and achieves the advantages of shortening the filling cycle, low filling cost and short curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

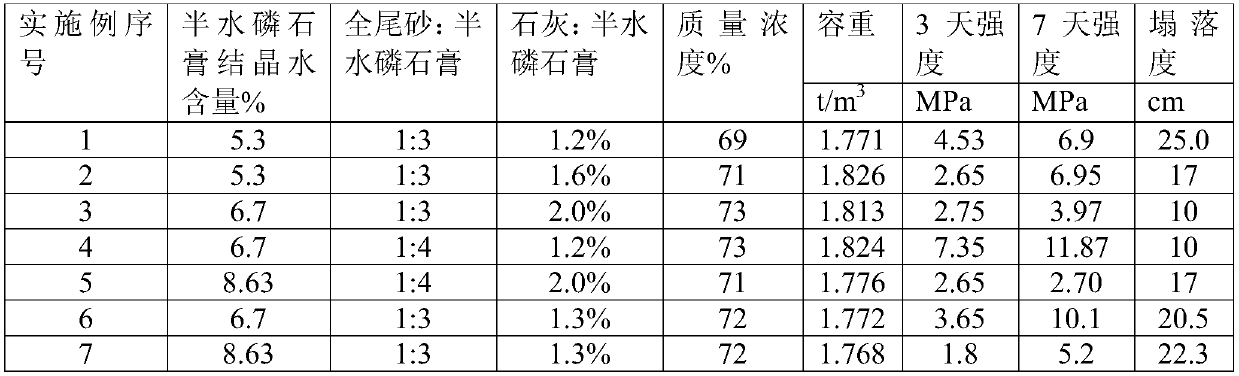

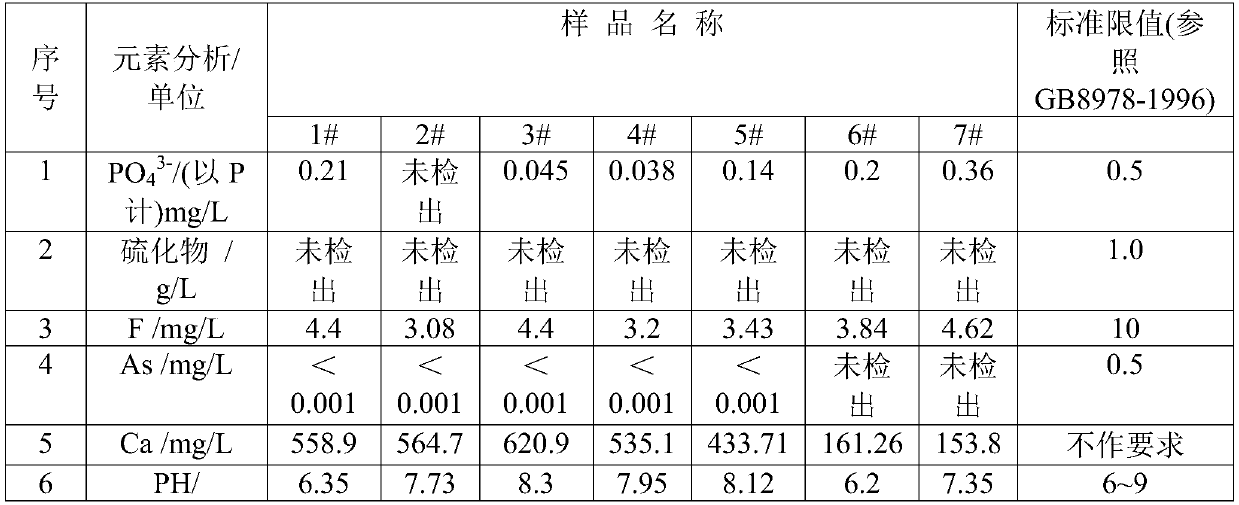

[0021] Embodiments 1 to 7: the whole tailings produced by the single reverse flotation process of the dressing plant and the hemihydrate phosphogypsum produced by the phosphoric acid production by the semi-wet method of the phosphating plant (the weight content of crystal water is 5.3~8.63%) ) according to the dry basis ratio of 1:3~1:4, lime and hemihydrate phosphogypsum according to the dry basis ratio of 1.2%~2.0%, then add water to mix and pour it into a horizontal mortar mixer for 3 minutes, and stir until the mass concentration is 69%~ 73% of the filling slurry was used to prepare the filling slurry used for downhole filling or experiments. The data of each embodiment are shown in Table 1. The filling slurry needs to be stirred evenly before it can be transported to the empty space in the well and solidified to form a high-strength cemented filling body.

[0022] According to GB / T50080-2002 "General Concrete Mixture Performance Test Method Standard", take the filling slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com