Sliding sleeve spray nozzle for open hole fracturing

An open-hole well and nozzle technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of loss of hydraulic energy, unexpected extension of nozzles, large loss of hydraulic capacity, etc., to reduce hydraulic capacity loss, Improved fixed-point performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

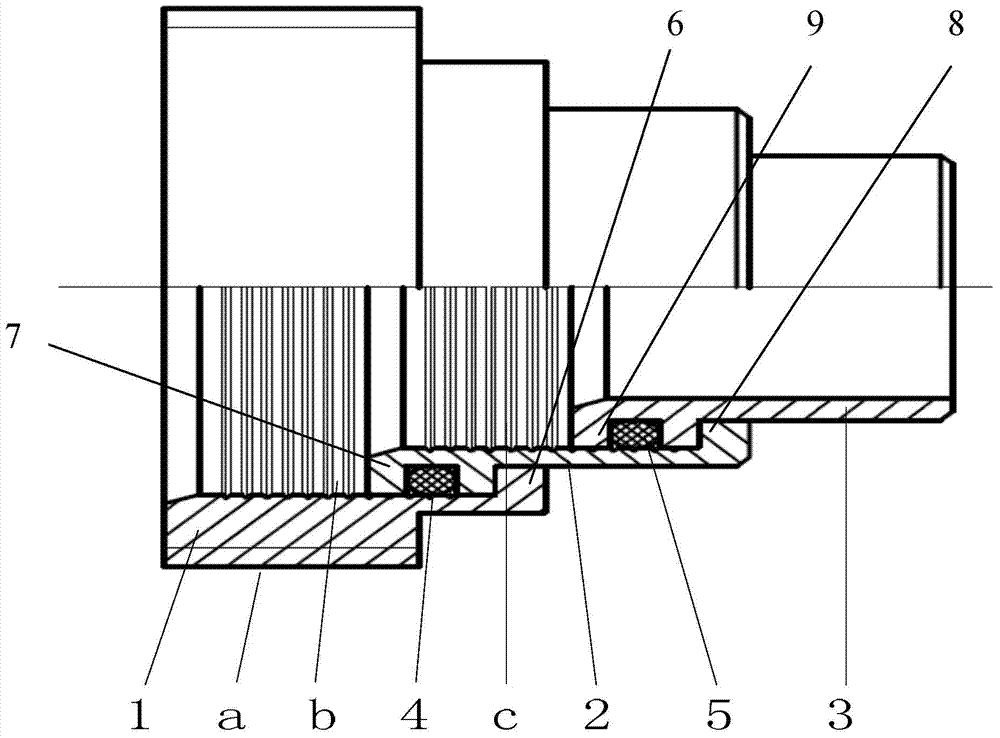

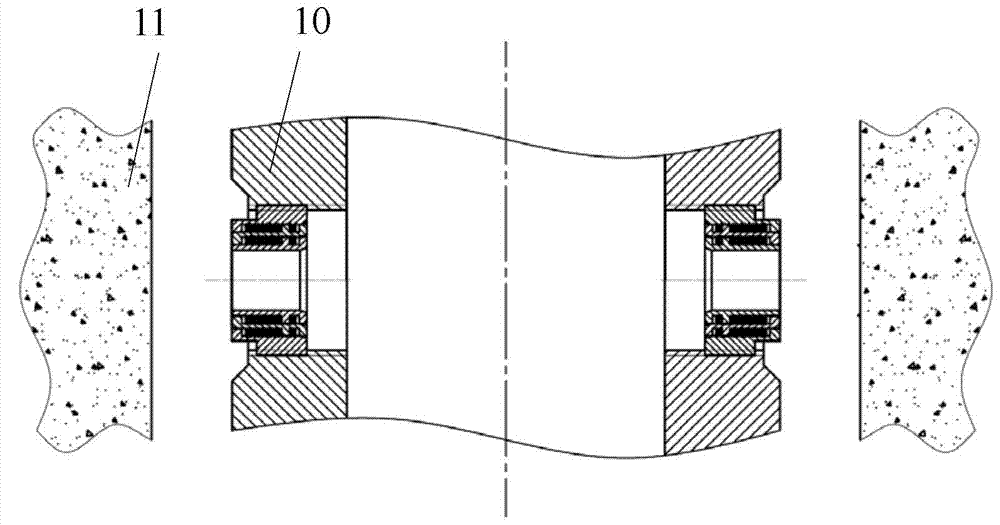

[0021] The specific structure of the slip-on nozzle of the present invention will be described below in conjunction with the accompanying drawings.

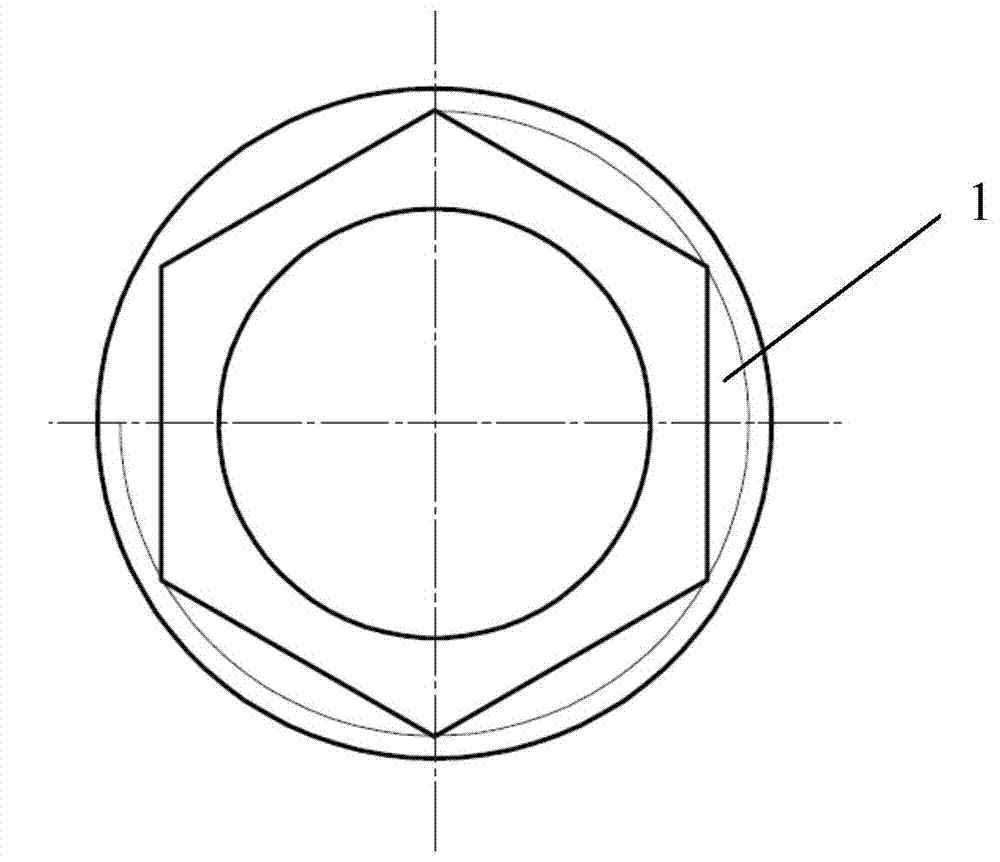

[0022] As shown in the figure, the sliding sleeve nozzle for open hole fracturing includes: a nozzle outer cylinder 1 , a nozzle middle cylinder 2 and a nozzle inner cylinder 3 which are sequentially nested together. The outer peripheral surface of the nozzle outer cylinder 1 away from the end of the nozzle middle cylinder 2 is formed with an external thread a, and the outer peripheral surface sleeved at the end of the nozzle middle cylinder 2 is in a hexagonal shape, and a limiting structure is formed at the corresponding socket to limit mutual detachment and leak-proof sealing structure. The nozzle middle cylinder 2 and the nozzle inner cylinder 3 can retract into the nozzle outer cylinder 1 or protrude from the nozzle outer cylinder 1 under the action of external force. The nozzle outer cylinder 1 is installed on the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com