Method for cleaning inner wall of casing, material thickness detection device, cleaning equipment and concrete mixer

A technology for thickness detection and cleaning machine, applied in cleaning methods and utensils, measuring devices, cleaning methods using liquids, etc., can solve problems such as potential safety hazards, artificial control of start and stop time, manual cleaning, etc., to reduce the workload of manpower , improve adaptability, avoid the effect of cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

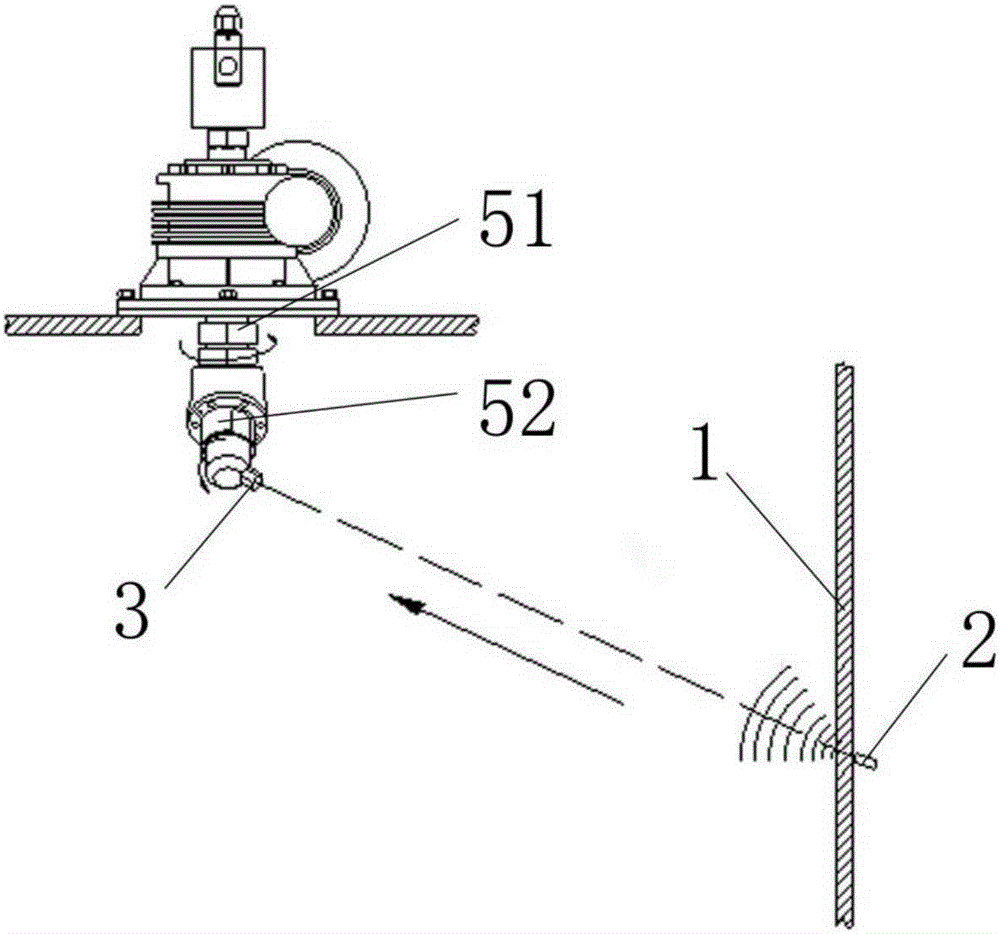

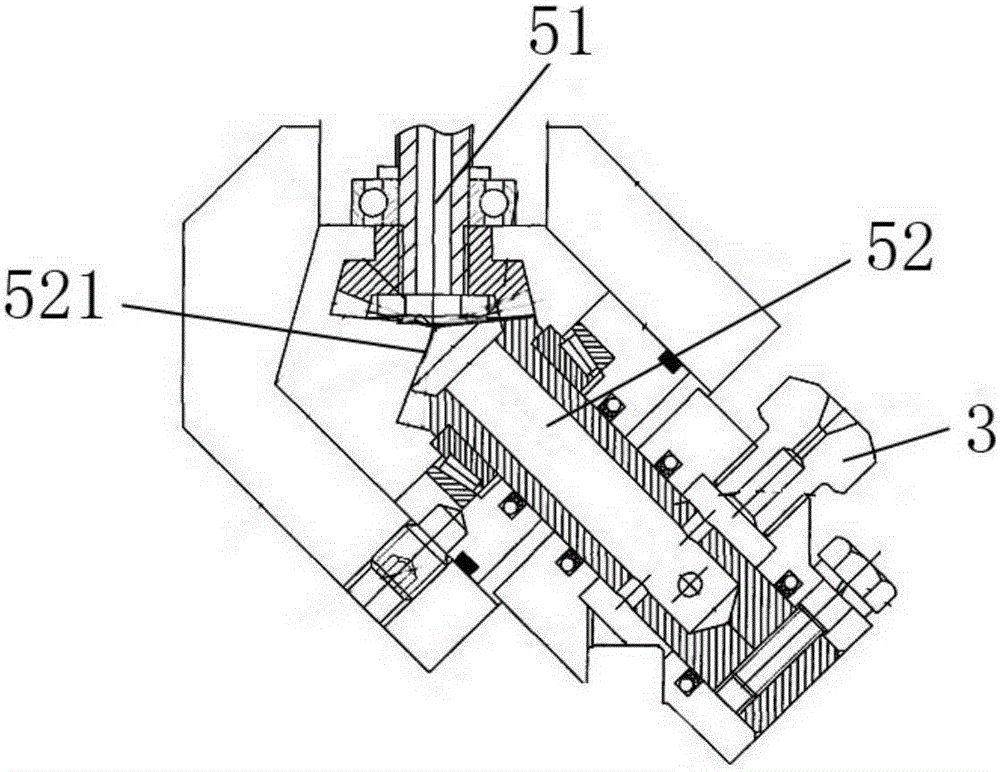

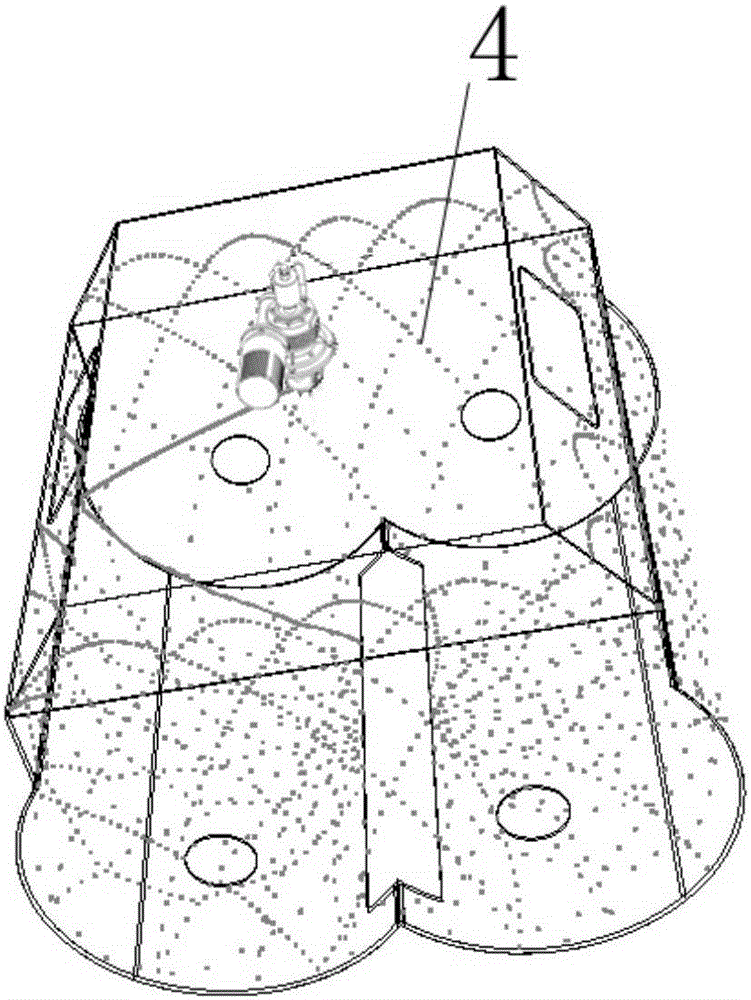

[0032] refer to figure 1 , the present invention firstly provides a method for cleaning the inner wall of the casing and a material thickness detection device. When concrete is contained in a container such as the cabinet 1 of a concrete mixer and adheres to the inner wall of the cabinet 1, the device of the present invention can detect the thickness of the concrete adhered to the inner wall of the cabinet 1, and Clean the adhered concrete in time.

[0033] According to the embodiment of the present invention, a device for detecting the thickness of the material adhered by ultrasonic signals is provided on the casing 1, and the device is used to detect the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com