Shield segment testing machine

A shield segment and testing machine technology is applied in the construction field to achieve the effects of good stress characteristics, simplified layout, and optimized test loading control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples are further detailed descriptions of the present invention.

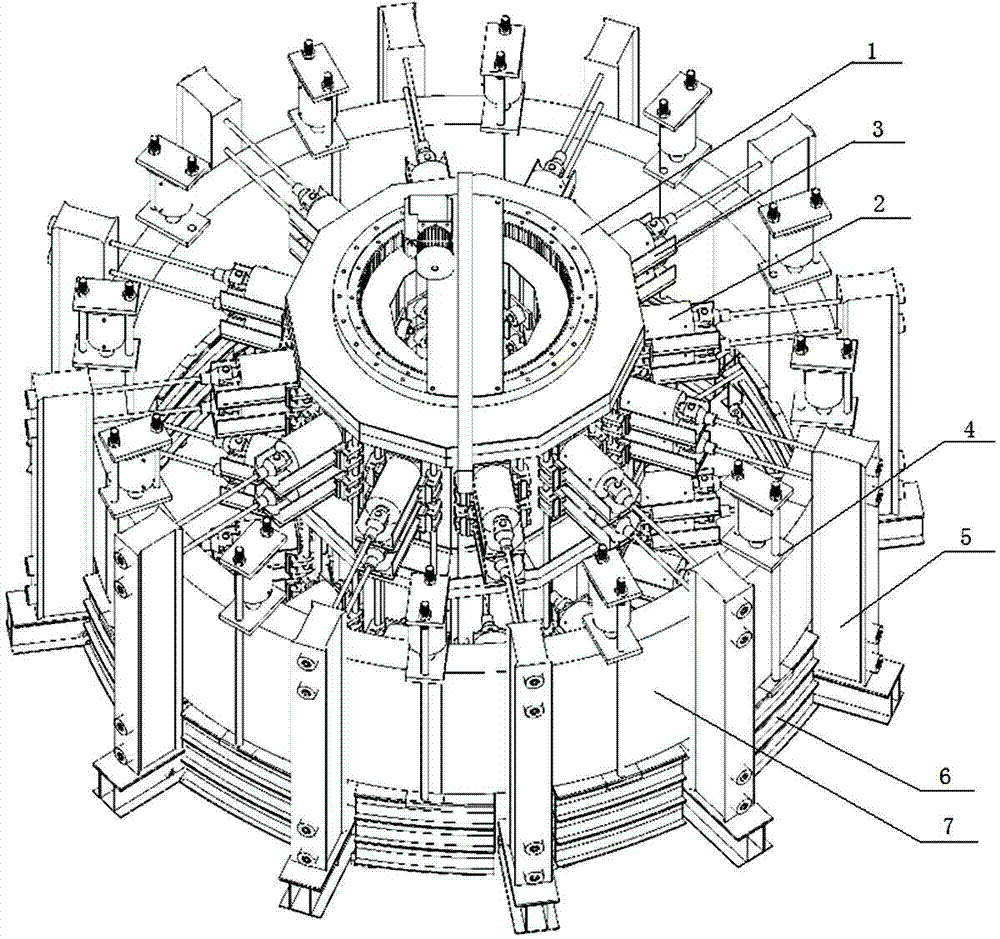

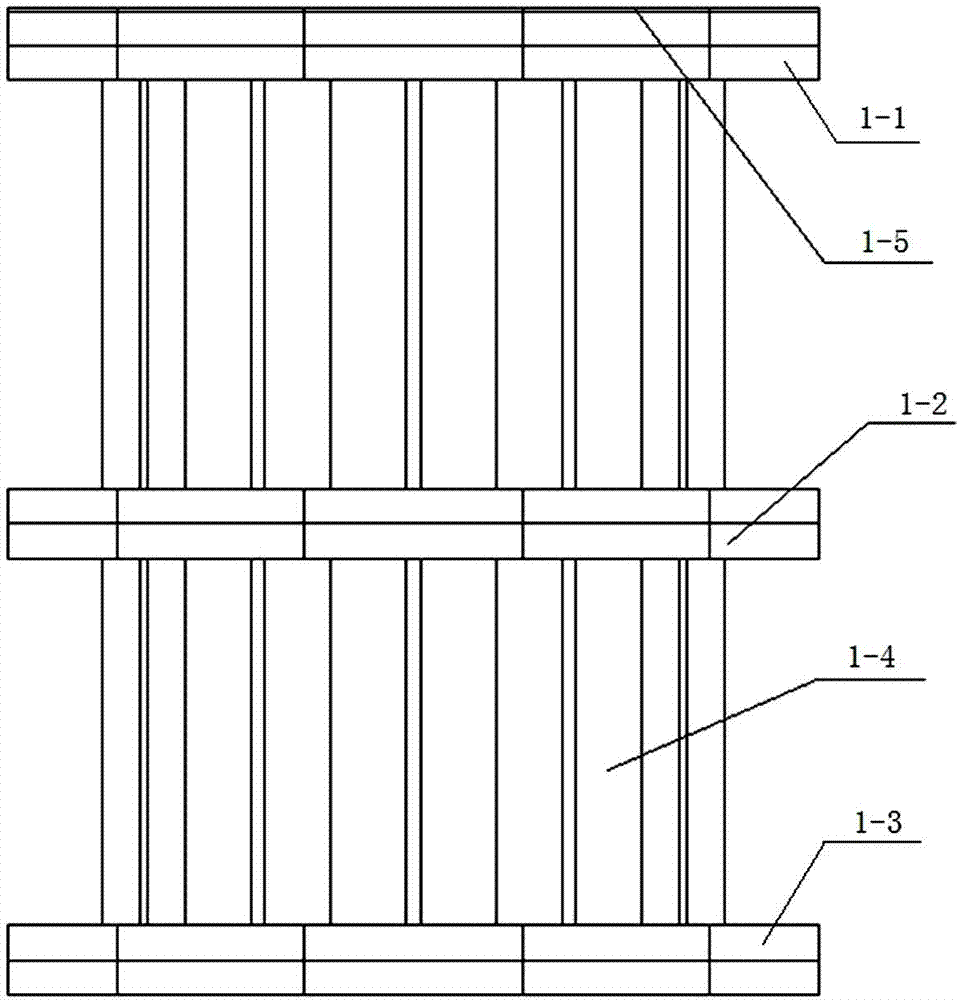

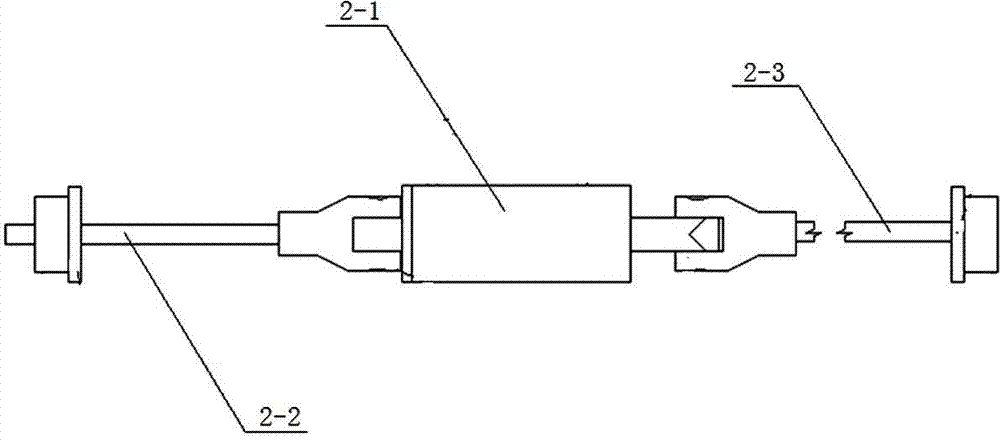

[0049] like figure 1 As shown: the shield segment testing machine of the present invention is composed of a self-balancing reaction force core tube 1, an oil cylinder force applying device 2, an axial force loading device 4, a loading beam 5 and a base 6; the base 6 is circular and located on the shield The bottom of the segment testing machine; the balanced reaction force core tube 1 is located at the center of the base 6; the shield segment ring 7 is located above the edge of the base 6; the loading beam 5 is a cubic structure, standing vertically on the base 6 and the shield tube The outer side of the segment ring 7; the two ends of the cylinder force applying device 2 are respectively connected to the self-balancing reaction force core tube 1 and the loading beam 5; the axial force loading device 4 is located on the shield segment ring 7; the self-balancing reaction force core tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com