Whole-process mechanized operation method for full-film double-furrow corn planting

A full-film double-furrow and full-process mechanization technology, which is applied in botany equipment and methods, horticulture, applications, etc., can solve problems such as poor performance, and achieve the effects of increasing emergence rate, increasing yield, and increasing soil organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

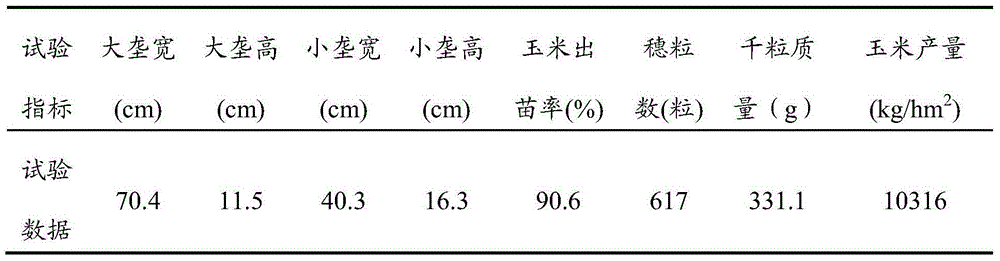

specific Embodiment 1

[0038] Specific embodiment 1: described full-film double-furrow corn planting full-process mechanized operation method comprises the following steps:

[0039]The first step, the activation of the rotten agent and herbicide: the rotten agent made of 40% yeast, 35% fermented filamentous bacteria and 25% photosynthetic bacteria, the blending of the rotten agent and water The ratio is 1:500; the rotten agent solution mixed with water is activated at 45°C for 9 hours. Blend 50% of acetochlor EC with water, add 60kg of water to every 50g of acetochlor EC, and activate the acetochlor EC solution mixed with water at 30°C for 3 hours;

[0040] The second step, mixed fertilizer blending: according to urea 375kg / hm 2 , phosphate fertilizer general calcium 825kg / mu, nitrogen-phosphorus ratio 1:0.6 for fertilizer matching, fully mix the solid fertilizer and place it for 0.5h;

[0041] The third step is to prepare for laying plastic film: select a black degradable plastic film with a thic...

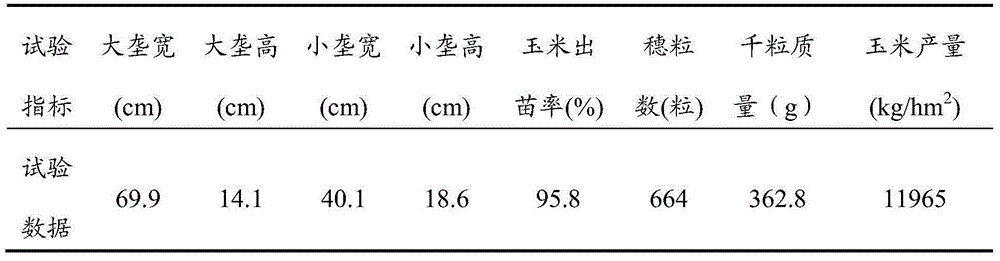

specific Embodiment 2

[0051] Specific embodiment 2: described full-film double-furrow corn planting full-process mechanized operation method comprises the following steps:

[0052] The first step, the activation of the rotten agent and herbicide: the rotten agent made of 40% yeast, 35% fermented filamentous bacteria and 25% photosynthetic bacteria, the blending of the rotten agent and water The ratio is 1:600; the rotten agent solution mixed with water is activated at 45°C for 10.5h. Blend 50% of acetochlor EC with water, add 60kg of water to each 60g of acetochlor EC, and activate the acetochlor EC solution mixed with water at 30°C for 4 hours;

[0053] The second step, mixed fertilizer blending: according to urea 375kg / hm 2 , phosphate fertilizer general calcium 825kg / mu, nitrogen-phosphorus ratio 1:0.7 for fertilizer matching, fully mix the solid fertilizer and place it for 0.8h;

[0054] The third step is to prepare for laying plastic film: select a black degradable plastic film with a thickn...

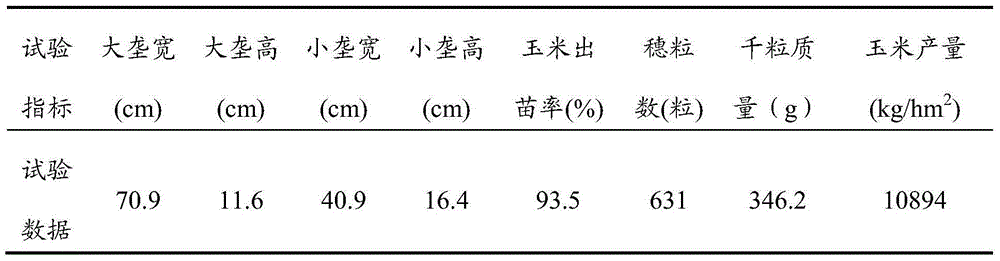

specific Embodiment 3

[0064] Specific embodiment 3: described full-film double-furrow corn planting full-process mechanized operation method comprises the following steps:

[0065] The first step, the activation of the rotten agent and herbicide: the rotten agent made of 40% yeast, 35% fermented filamentous bacteria and 25% photosynthetic bacteria, the blending of the rotten agent and water The ratio is 1:700; the rotten agent solution mixed with water is activated at 45°C for 11.5h. Blend 50% of acetochlor EC with water, add 60kg of water to each 65g of acetochlor EC, and activate the acetochlor EC solution mixed with water at 30°C for 5 hours;

[0066] The second step, mixed fertilizer blending: according to urea 375kg / hm 2 , phosphate fertilizer general calcium 825kg / mu, nitrogen-phosphorus ratio 1:0.8 to match the fertilizer, fully mix the solid fertilizer, and place it for 1.0h;

[0067] The third step is to prepare for laying plastic film: select a black degradable plastic film with a thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com