Comb gulleting machine

A comb and frame technology, applied in the field of comb gear opening machines, can solve the problems of short distance, low machining accuracy, fast machine wear, etc., and achieve the effect of simple equipment structure and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

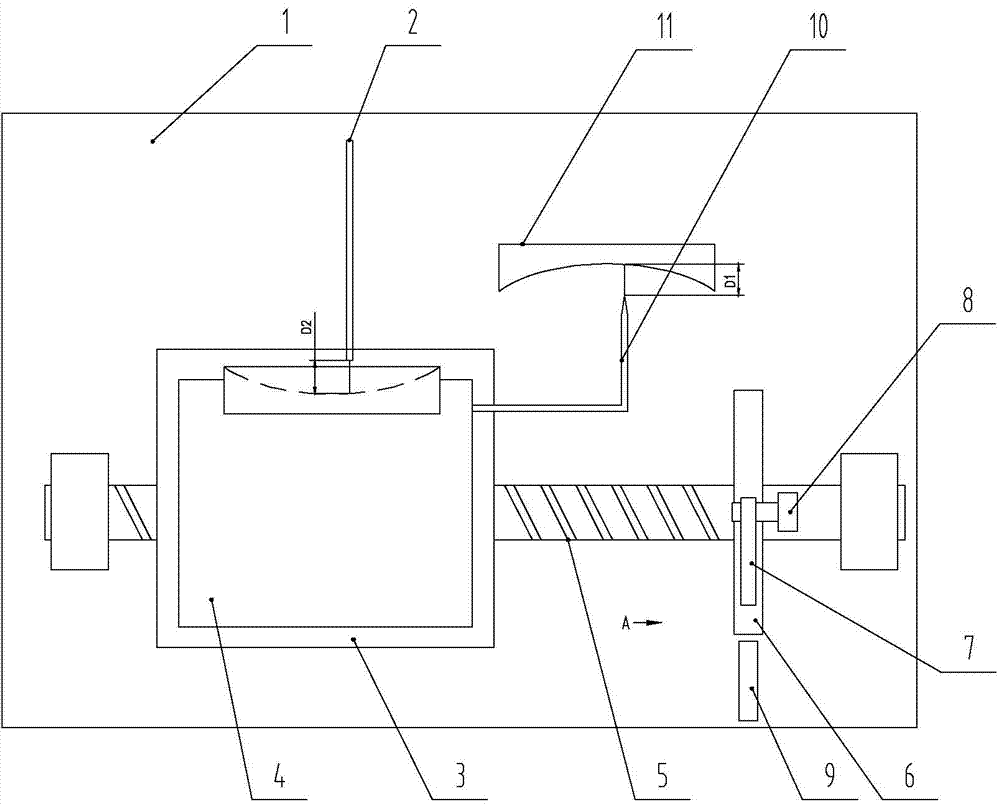

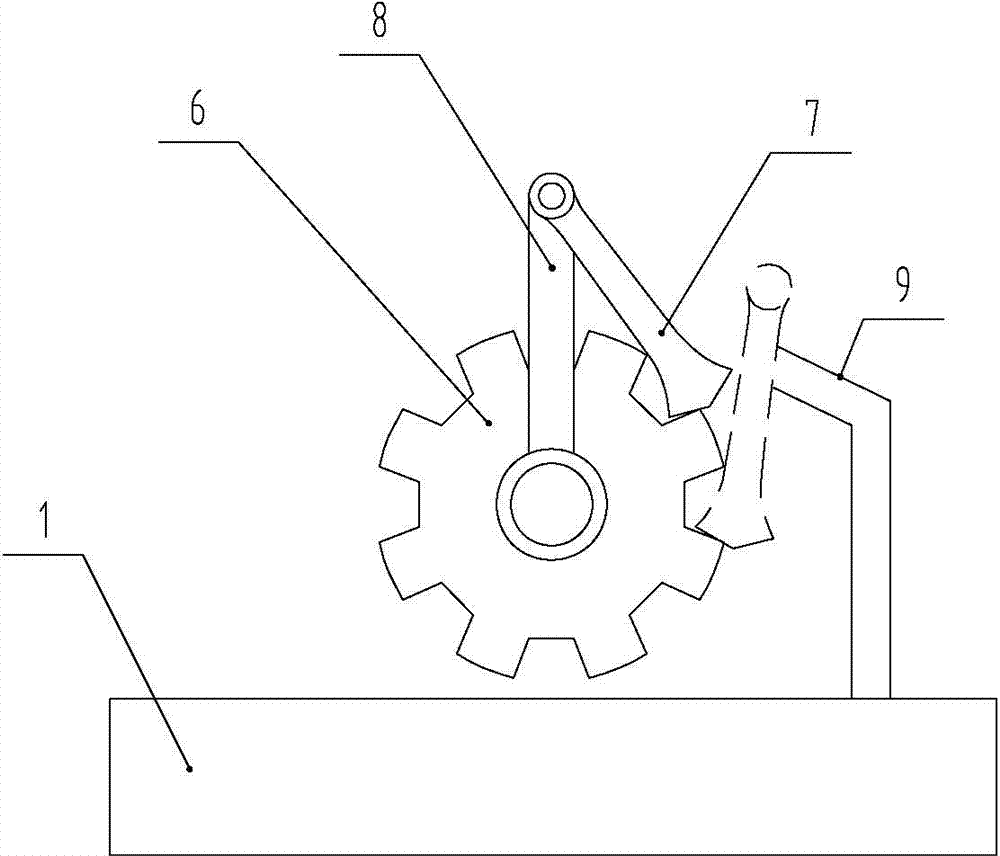

[0013] The present invention will be described in detail below with reference to the accompanying drawings, as shown in the figure: The comb-opening machine of this embodiment includes a frame 1, a rotating cutting wheel 2, a working table 3, and a pallet 4 on the working table 3. The working table 3 is driven by the ball screw nut pair 5 to move along the axis parallel to the cutting wheel 2. The pallet frame 4 is slidingly fitted with the working table 3 and clamps the comb relative to the cutting wheel to cut teeth. The ball screw sleeve In the ratchet wheel 6, the ratchet wheel 6 is rotated by the ratchet pawl 7 which is driven by the rocker 8. The top of the ratchet pawl 7 is hinged with the rocker 8 and the pawl 7 can rotate around the hinge point to rotate the rocker 8 Both sides drive the ratchet wheel 6 to rotate in both directions, the pawl 7 drives the ratchet wheel to rotate intermittently, and the rocker 8 drives the worktable to the initial position. The pallet fra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap