Combined subsonic air intake device of aircraft

A technology for air intake devices and aircraft, which is applied in the direction of combustion at the intake port of a power plant, and can solve the problem of poor flow field distortion at the outlet of the buried air intake, low recovery coefficient of the total pressure of the buried air intake, and Problems such as large distortion of the flow field at the outlet of the airway, to achieve the effect of ensuring long-range flight capabilities, RCS stealth penetration capabilities, and good airflow distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

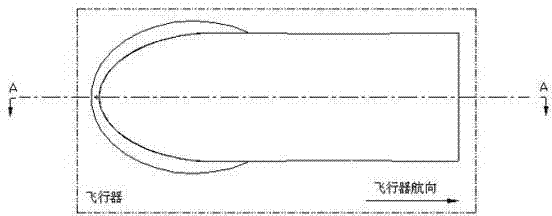

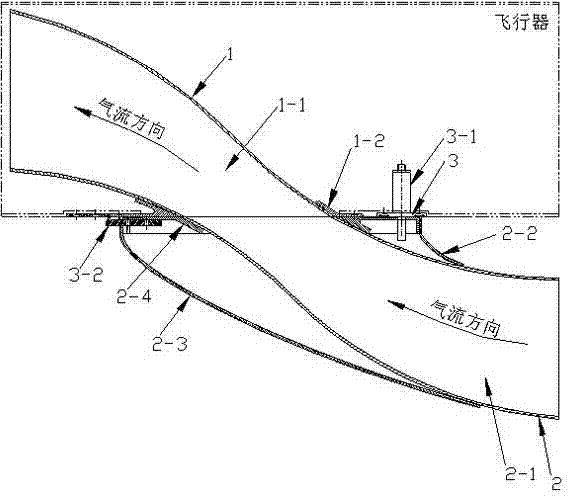

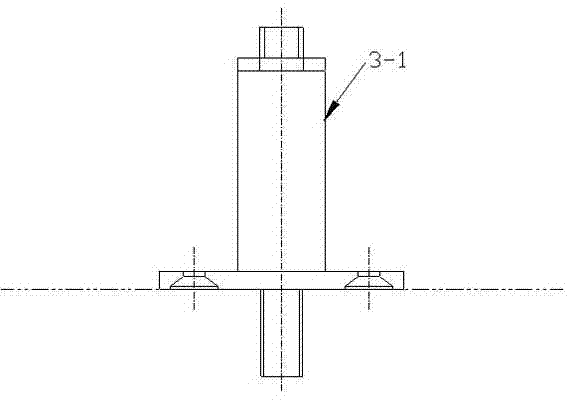

[0031] as attached figure 1 , attached figure 2 And attached image 3 As shown, the aircraft combined subsonic air intake device 1 includes a buried air intake 1, an external air intake structure 2, and an automatically separable connection mechanism 3, and the embedded air intake 1 includes a fixed air intake channel 1- 1 and fixed flange 1-2, external air intake structure 2 includes throwable air intake channel 2-1, front fairing 2-2, rear fairing 2-3 and throwable flange 2-4, which can be automatically The separated connecting mechanism 3 includes an explosive bolt 3-1 and a connecting piece 3-2. The throwable air intake channel 2-1, the front fairing 2-2 and the rear fairing 2-3 are installed and fixed on the throwable flange 2-4 with connectors, and the fixed intake channel 1-1 is installed and fixed with connectors To the fixed flange 1-2.

[0032] The fixed flange 1-2 of the embedded air intake 1 is installed and fixed on the aircraft with connectors, and the throw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com