Shaft body placing frame

A technology for placing racks and shafts, applied in the directions of external frames, packaging, external accessories, etc., can solve the problems of shaft damage, disordered arrangement, and inconvenient packaging trucks, so as to ensure space, avoid damage, and facilitate The effect of moving back and forth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

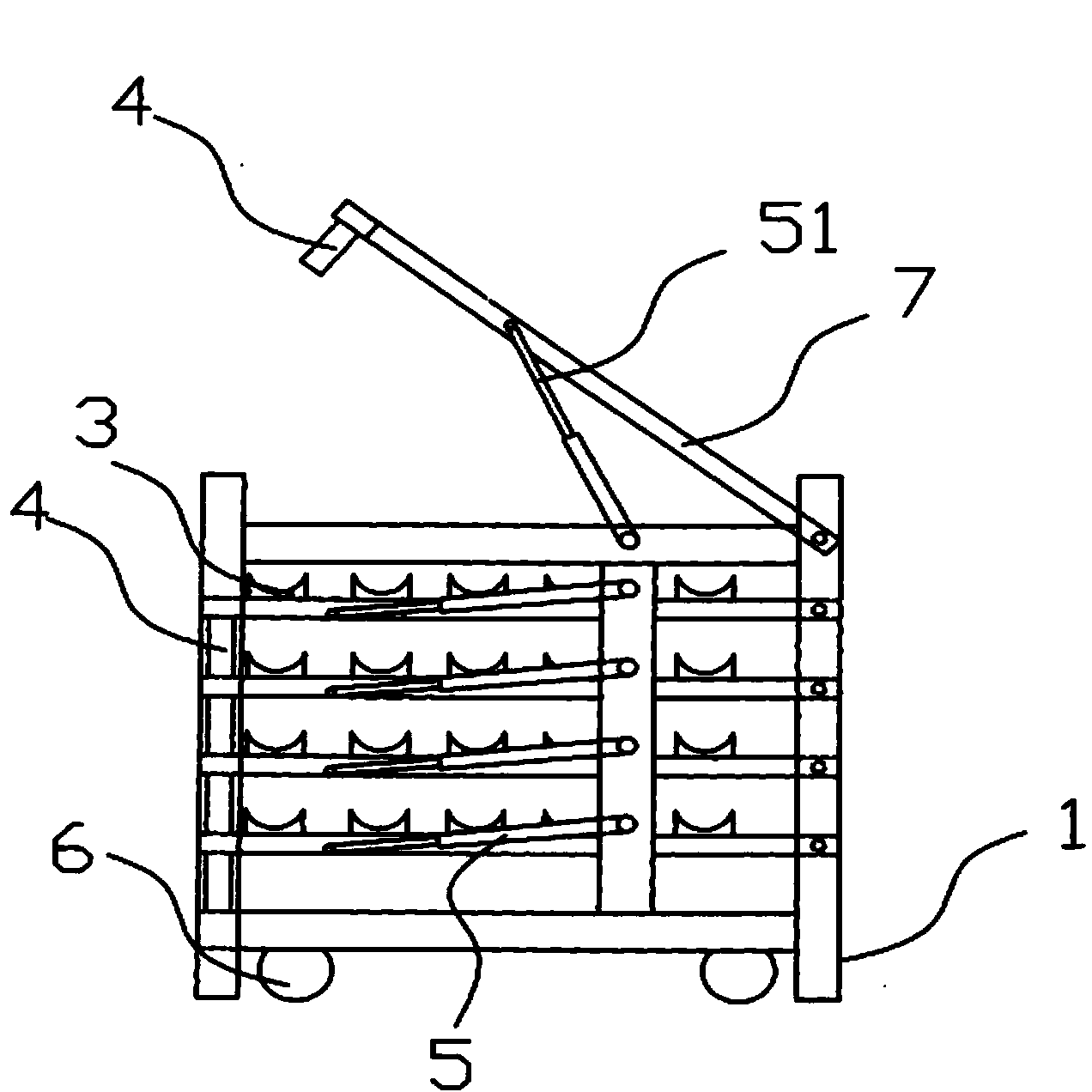

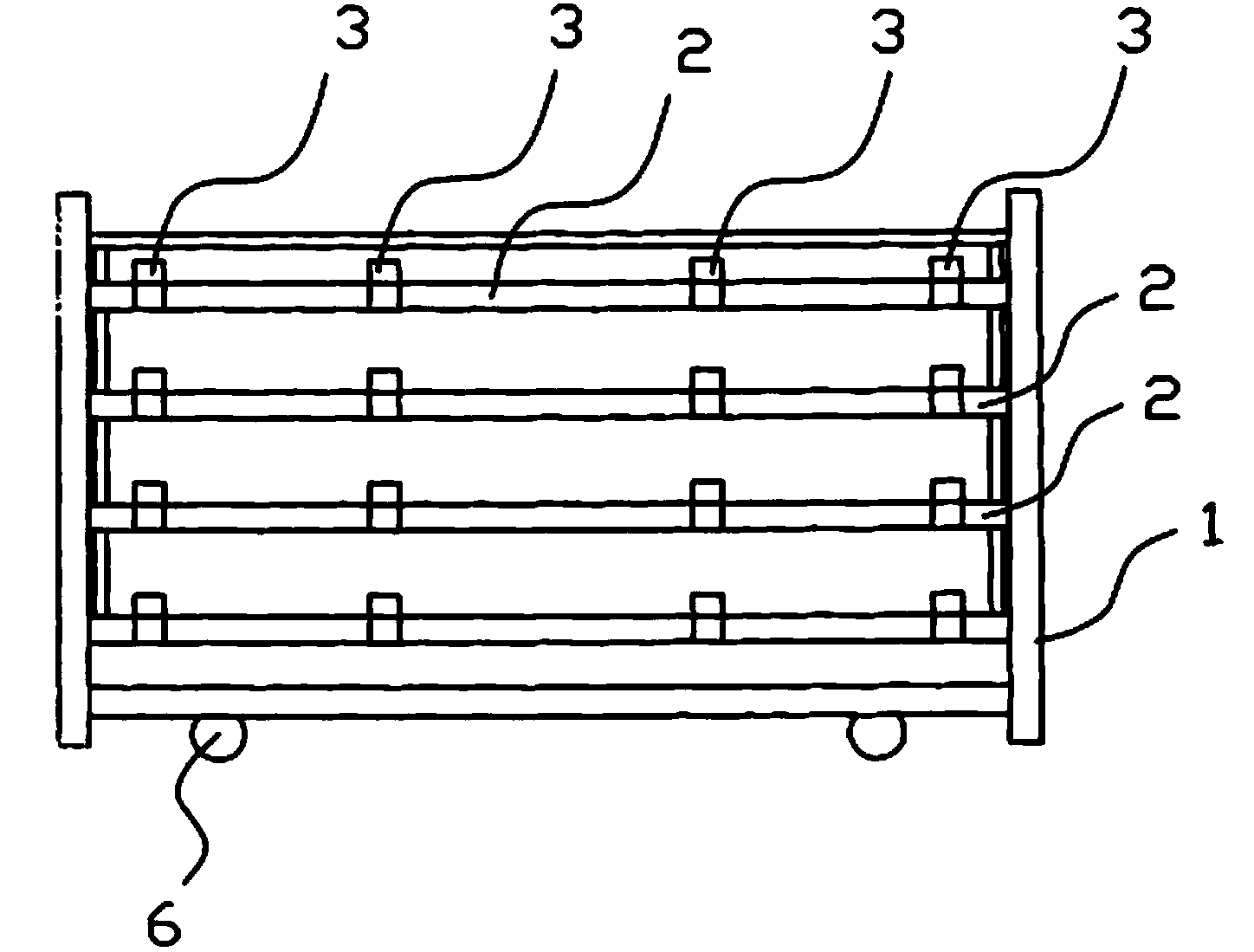

[0018] like figure 1 , figure 2 As shown, a shaft mounting frame includes a main body 1. The main body 1 is provided with several partition plates 2 in the horizontal direction. Both sides of the partition plate 2 are respectively connected with the main body 1 through adjusting rods 5 .

[0019] The top of the main body 1 is provided with a protection rod 7 , and both sides of the protection rod 7 are connected with the main body 1 through adjustment rods 51 .

[0020] The card slot 3 is made of rubber, and its shape is semicircle.

[0021] The clamping line 4 on both sides of the partition plate 2 is also made of rubber, and its bottom end faces against the upper end face of the partition plate 2 below.

[0022] The bottom of the main body 1 is provided with several pulleys 6 .

[0023] Those of ordinary skill in the art shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com