Connecting rod mechanism

A connecting rod mechanism and connecting rod technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of large kinetic energy consumption, easy deviation of the stacking position of section steel, and increased production costs , to achieve the effect of reducing production cost, ensuring accurate positioning and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0010] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

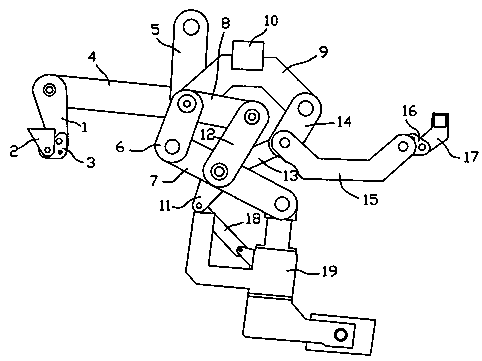

[0011] Such as figure 1 The shown linkage mechanism is composed of multiple connecting rods connected to each other. After outputting power through an oil cylinder, the connecting rods interact to realize the front, rear, up and down motion of the magnet swing arm 19 . The first fixed block 2, the second fixed block 10 and the third fixed block 17 are all fixed on the frame, and are movably connected by a first triangular connecting plate 3 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com