Cable reeling device

A winding device and cable technology, applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of troublesome installation and disassembly, time-consuming and labor-consuming, and reduced production efficiency, and achieve convenient installation and disassembly, The effect of saving time for fixing screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

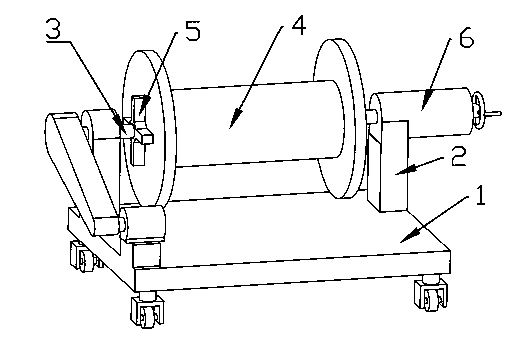

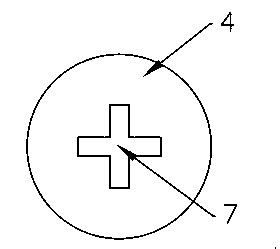

[0009] Such as figure 1 A cable winding device shown includes a base 1, a roller support 2 is installed on the base 1, a pair of roller shafts 3 are arranged on the roller support 2, and a roller shaft 3 is installed on the roller shaft 3. The cylinder 4, the roller 4 and the roller shaft are fixed by the cross fixed disk 5, the side wall of the roller 4 is provided with a groove 7 matching the cross fixed disk 5, and one end of the roller shaft 3 is installed with Regulator 6. The present invention adjusts the cross fixed disc through the adjusting device so that it can be embedded in the groove of the roller, which saves the time for fixing the screws and makes the installation and disassembly more convenient.

[0010] The present invention is not limited to the foregoing specific embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com