Fixing structure based on interior of centrifugal device

A fixed structure and centrifugal equipment technology, applied in lighting and heating equipment, drying solid materials, drying solid materials without heating, etc., can solve the problems of insufficient product purity, increased cost, energy consumption, etc., to achieve high purity and simple principle , The effect of small force deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

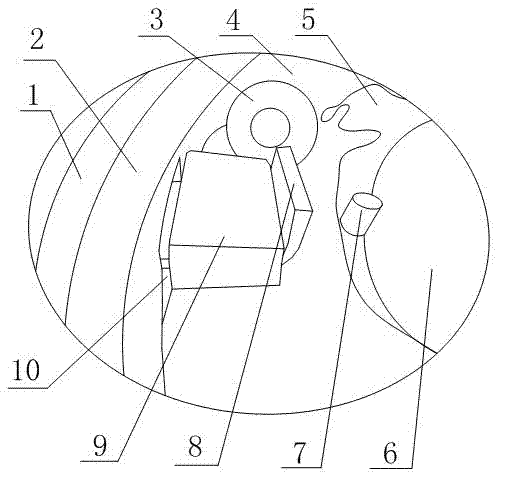

[0015] Such as figure 1 As shown, based on the internal fixed structure of the centrifugal device, it includes a filter cartridge 2, a fixed ring 4 is arranged inside the filter cartridge 2, several fixed holes-10 are uniformly arranged on the wall surface of the filter cartridge 2, and the fixed ring 4 is provided with Several fixing plates 9 in a U-shaped structure, and both ends of the fixing plates 9 are arranged on the fixing ring 4, and several L-shaped latches 8 are evenly arranged on the fixing ring 4, and each latch 8 One end passes through the gap between the fixing plate 9 and the fixing ring 4 and enters into the corresponding fixing hole 10 . The latch 8 is L-shaped, one end passes through the inside of the U-shaped fixed plate 9, and the vertical end serves as a positioning function, which is convenient for the operator to disassemble, and can realize the function of clamping. The fixed plate 9 is evenly distributed on the fixed ring 4, so that The force is unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com