Novel mop spin-drying barrel

A new type of mop and drying bucket technology, which is used in carpet cleaning, floor cleaning, cleaning equipment and other directions, can solve the problems of disassembly, cleaning, time-consuming and laborious, and long drying time, and achieves durable and low manufacturing costs. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

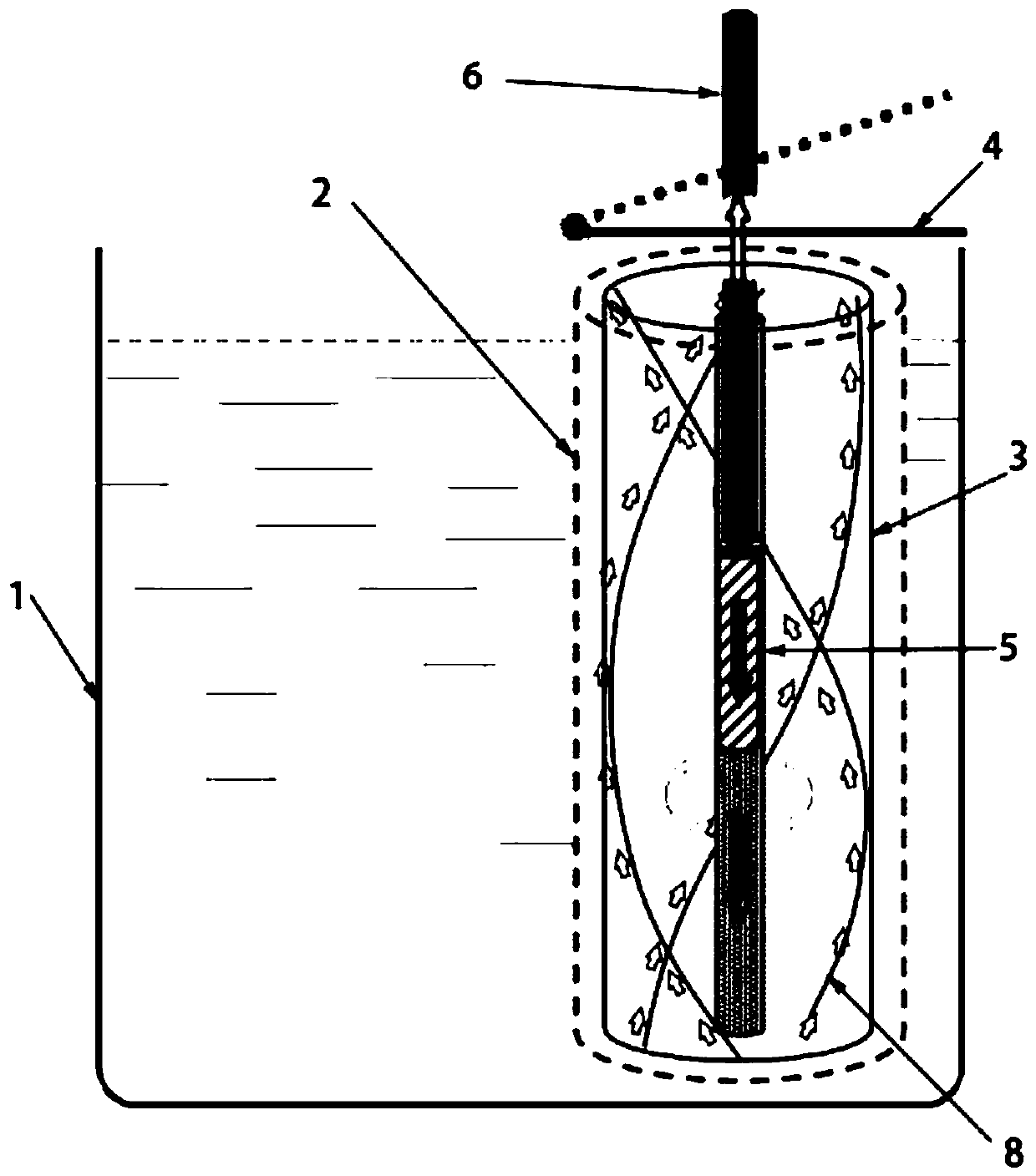

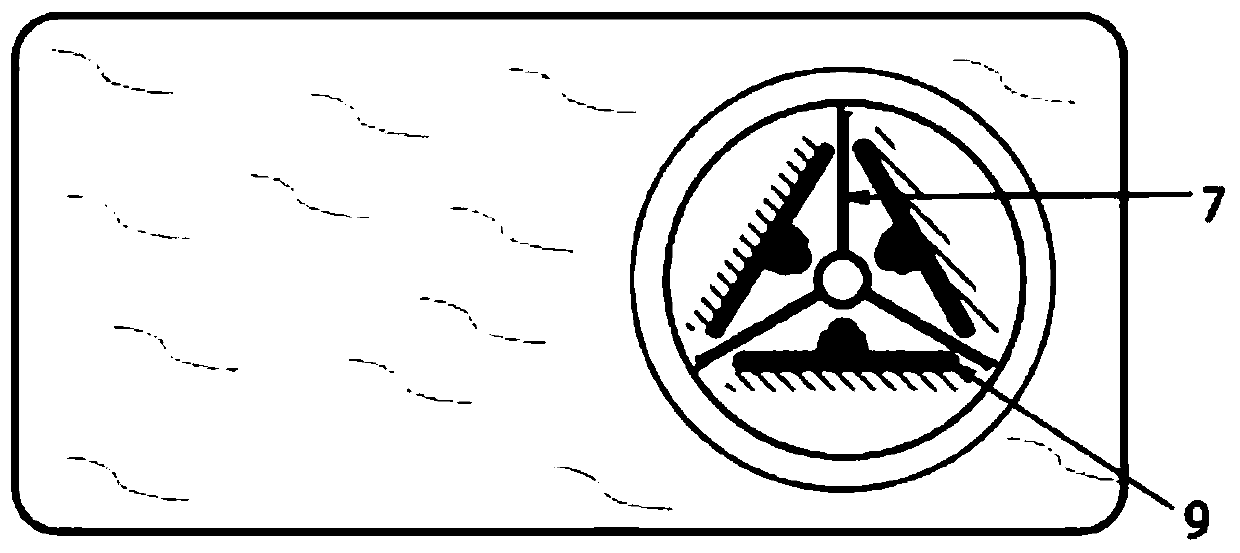

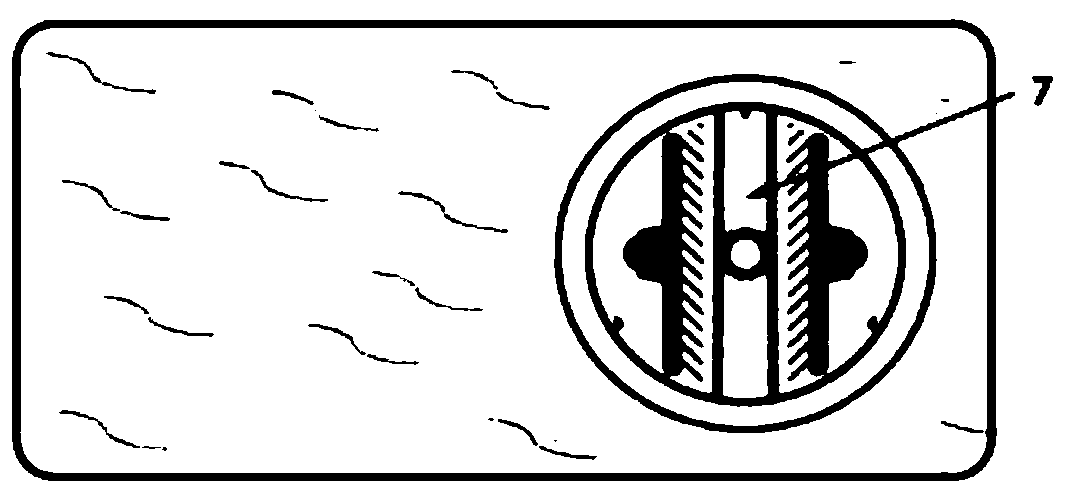

[0017] When the present invention is actually implemented, a novel mop drying bucket includes a water storage bucket 1, a water-proof bucket 2, a drying bucket 3, a transparent upper cover 4, a downward pressure rotating device 5, a mop rod 6, and an inner partition of the drying bucket 7. Water guide groove 8, mop head 9, the water storage bucket 1 is a hollow cuboid structure, the transparent upper cover 4 is arranged above the water storage bucket 1, and is fixed to the upper edge of the water storage bucket 1 through the connecting shaft , the described water-proof bucket 2 is located in the water-storage bucket 1 and is in the shape of a hollow cylinder without a cover. The water bucket 2 is coaxially assembled, and the inner wall of the drying bucket 3 is provided with three water guide grooves 8. The water guide grooves 8 are arranged in a spiral shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com