A shielded grounding card card body mold

A technology of shielding grounding and clamping body, which is applied in the field of shielding grounding card clamping body mold, which can solve the problems of high manufacturing cost, low production efficiency, and scrapping, and achieve the effects of reducing product scrapping rate, improving production efficiency, and avoiding oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

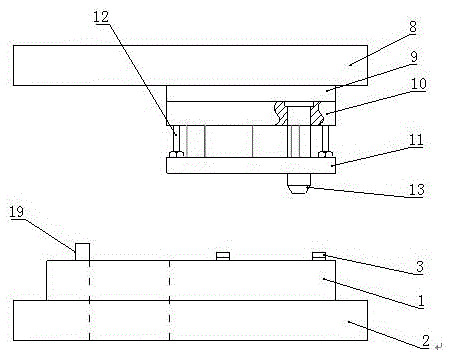

[0014] see figure 2 , the present invention discloses a shielding grounding card body mold structure, which consists of an upper mold part and a lower mold part,

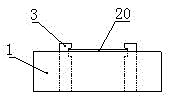

[0015] The lower die includes a die 1 and a lower die base 2, and the die 1 is installed on the lower die base 2, such as image 3 As shown, the feed side of the die 1 is provided with two pairs of feed guide blocks 3 positioned at both sides of the copper strip, the upper end of the feed guide blocks 3 stretches out from the upper surface of the die 1, and each pair of feed guide blocks 3 The inner side is correspondingly provided with a guide groove, and the guide groove is flush with the upper surface of the die 1 .

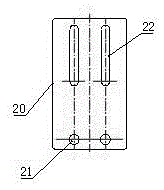

[0016] Such as Figure 4 As shown, the upper surface of the die 1 is sequentially provided with a circular blanking hole 4, a waist-shaped blanking hole 5, a dumbbell-shaped blanking hole 6 and a blanking cavity from the feed side to the discharge side on the moving path of the copper strip. 7. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com