Locking mechanism

A technology of locking mechanism and locking parts, which is applied to the packaging of vulnerable items, internal accessories, and types of packaged items. It can solve problems such as unstable road conditions, damage to ultrasonic equipment, and complex structures, so as to avoid shaking or falling down and improve performance. The effect of stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

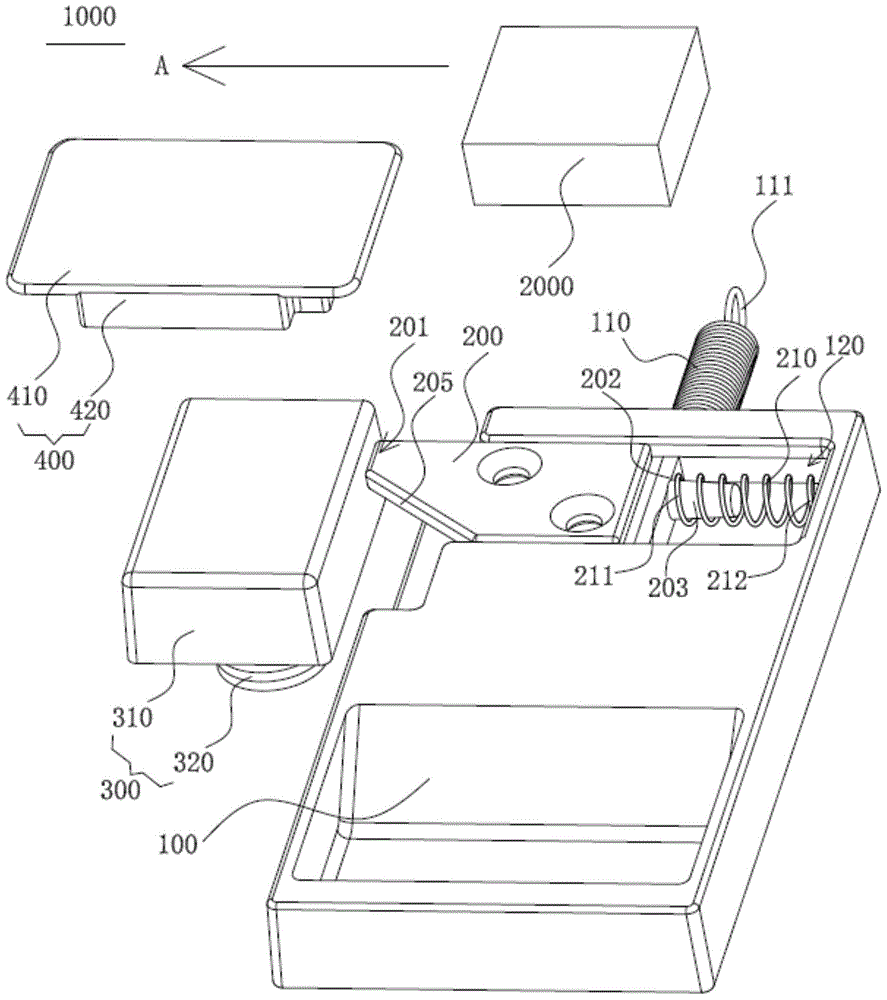

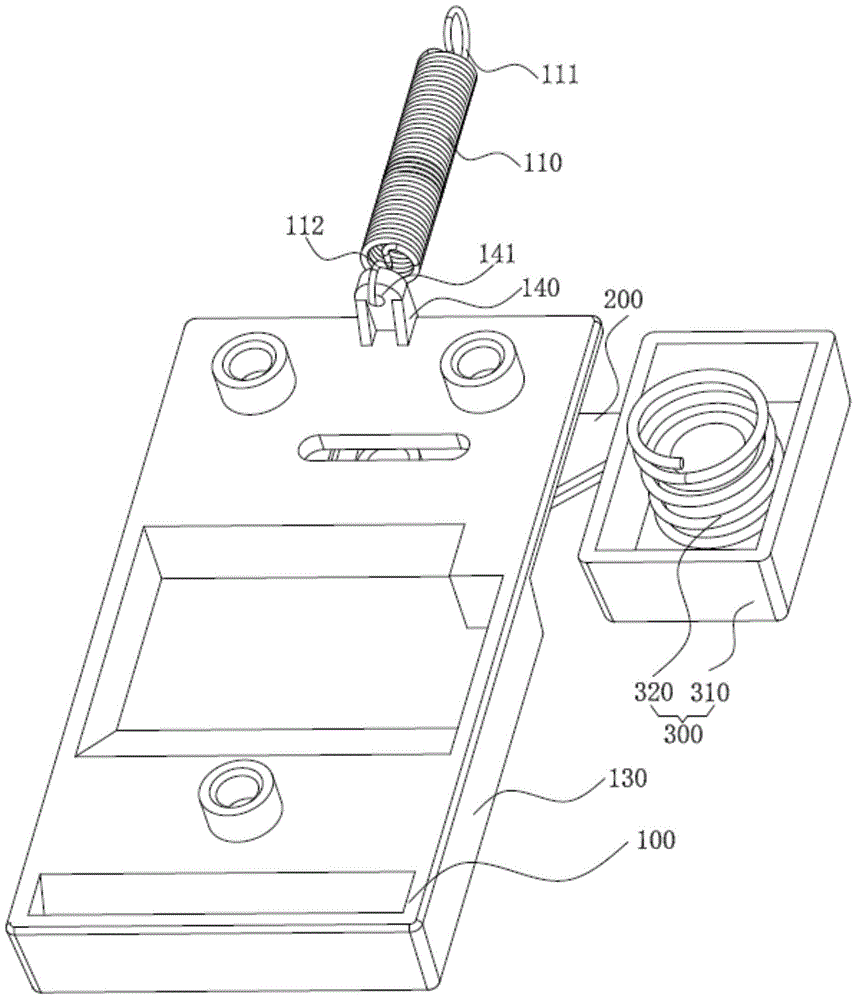

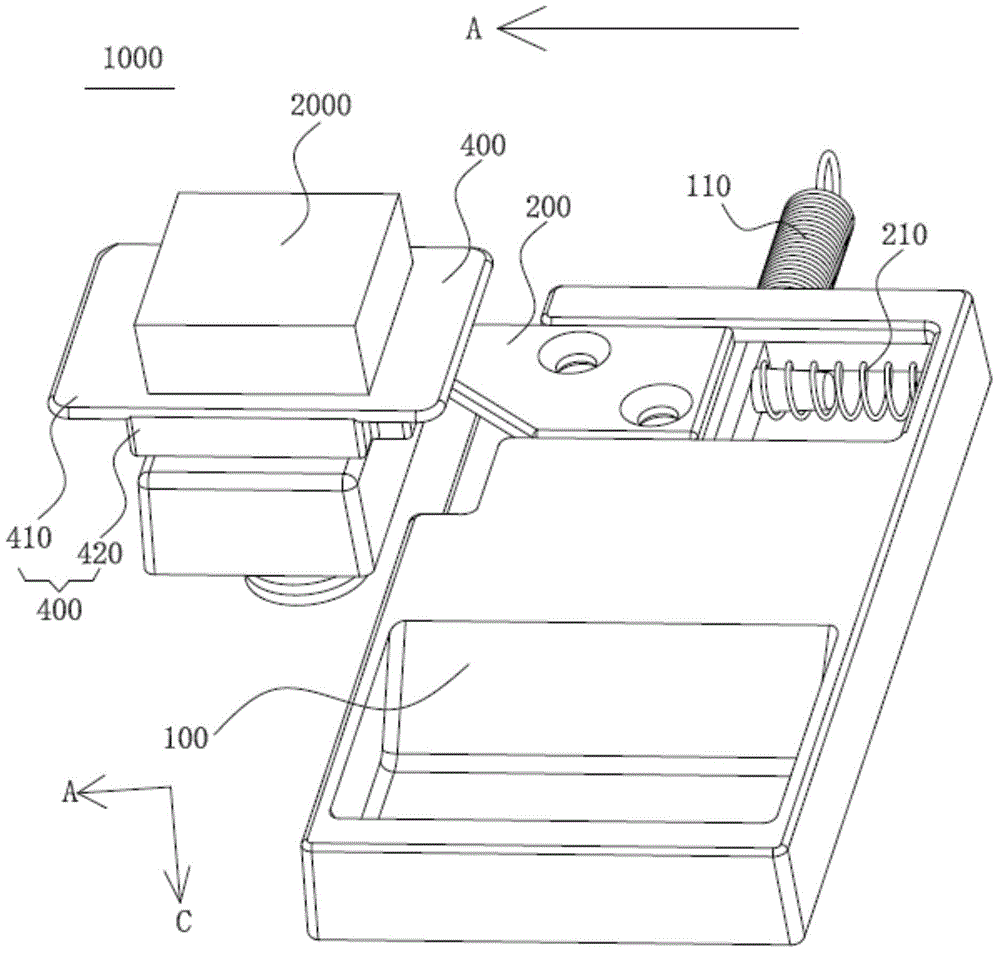

[0025] Please refer to figure 1 , figure 2 , figure 1 It is a front perspective schematic view of the locking mechanism of the present invention; figure 2 It is a perspective view of the bottom surface of the locking mechanism of the present invention. The locking mechanism 1000 of the present invention is used to lock the device 2000 to be locked. The locking mechanism 1000 includes a base 100 , a locking member 200 , at least one first elastic member 210 , and a supporting member 400 . It should be noted that, for the convenience of explanation, figure 2 The supporting member 400 is not shown in the figure.

[0026] The base 100 has a first side 130 , and the first sliding rail 120 is disposed on the base 200 . The locking member 200 is disposed on the first sliding rail 120 and can move back and forth in a first direction A relative to the base 100 along the first sliding rail 120 . The locking member 200 has a first end 201 and a second end 202 opposite to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com