Preparation method for lutetium-aluminum garnet-based transparent ceramic

A technology of lutetium aluminum garnet and transparent ceramics, which is applied in the field of preparation of lutetium aluminum garnet-based transparent ceramics, can solve problems such as unsuccessful commercialization and accelerate the industrialization process of lutetium aluminum garnet-based transparent ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

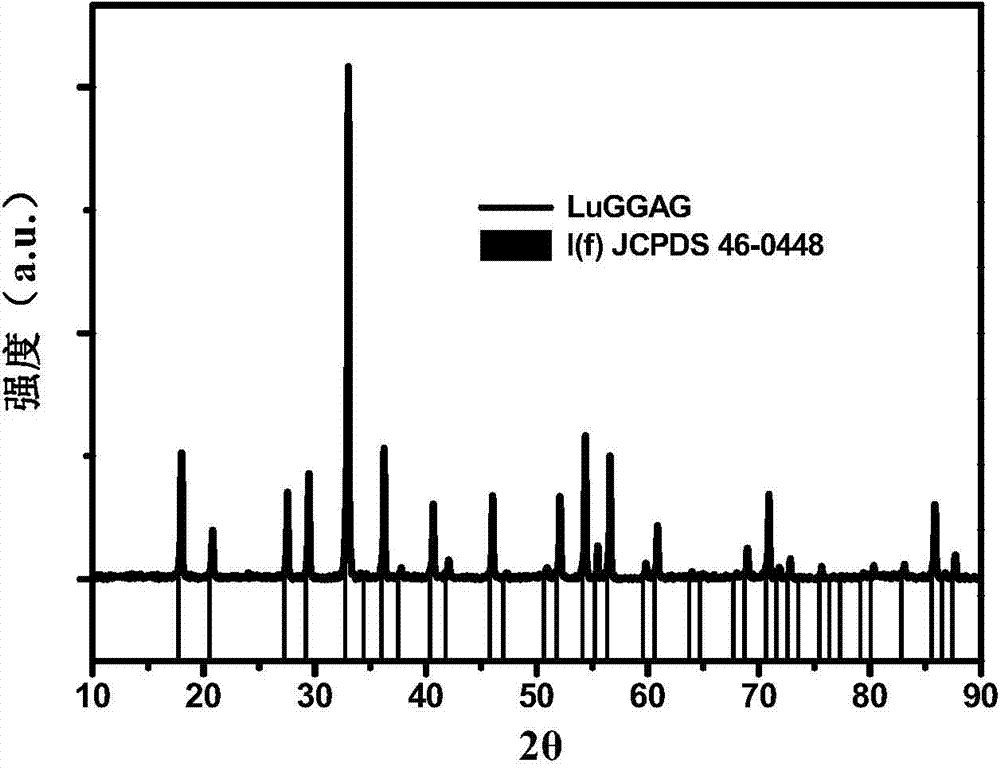

[0063] Preparation method of lutetium aluminum garnet-based transparent ceramics

[0064] The lutetium-aluminum-garnet-based transparent ceramics of the present invention use oxides of A, B, C, D, and E as raw materials, and are prepared by co-precipitation or ball milling. After the precursor powder is prepared, the precursor powder is sequentially subjected to thermal spraying process, molding process, sintering process, hot isostatic pressing process and annealing process to obtain the lutetium aluminum garnet-based transparent ceramic of the present invention.

[0065] Wherein A is an element selected from the following group: Ce, Pr, Nd, Sm, Eu, Dy, Ho, Er, Tm, Ti, Cr or Mn; B is an element selected from the following group: Y, La, Gd, Tb Or Yb; C is Lu element: D is Ga or Sc element: E is Al element. The molar ratio of each element in the raw material satisfies the following general formula: x: (1-y) × (m-x): y × (m-x): (1-z) × (8-m): z × (8-m), Wherein, x is 0.00005-0...

Embodiment 1

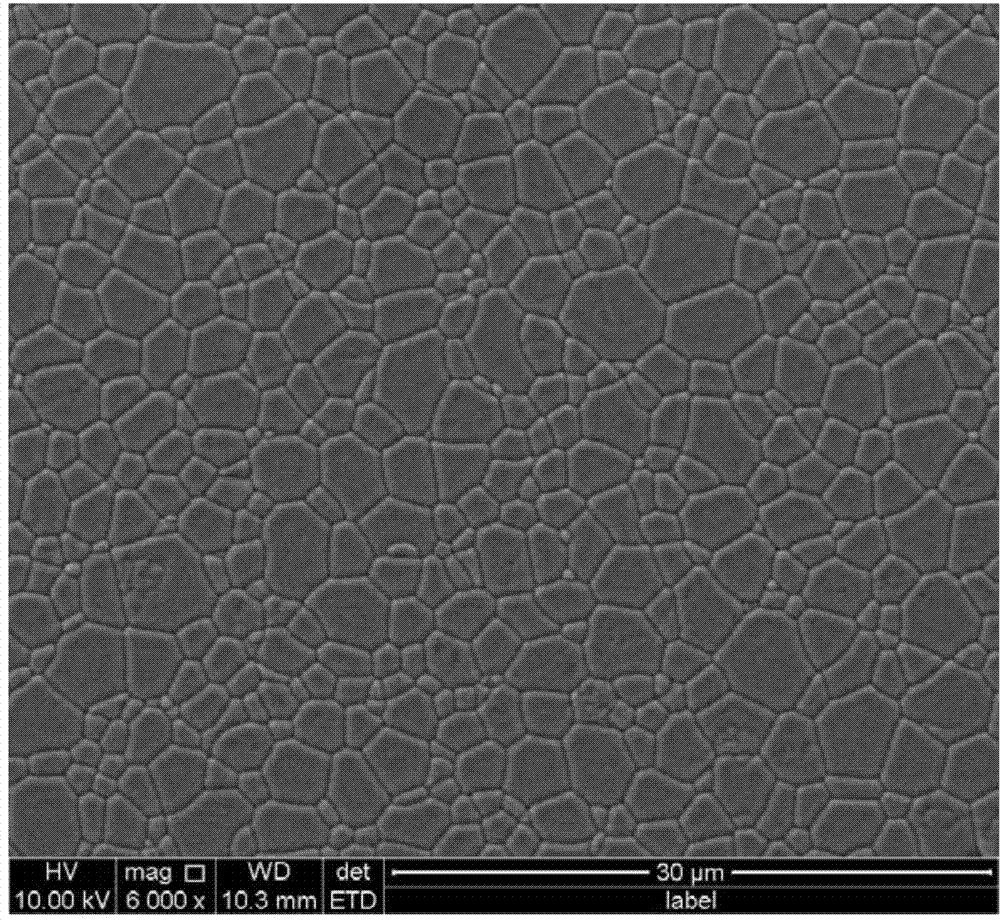

[0097] In this embodiment, a ball milling process, a thermal spraying process and a hot isostatic pressing process are combined to prepare lutetium aluminum garnet-based transparent ceramics. details as follows:

[0098] (1) Commercially available high-purity (99.99%) Lu 2 o 3 (2μm), Gd 2 o 3 (2μm), Al 2 o 3 (0.2μm), Ga2O3(2μm), CeO 2 (50nm) as the starting material, according to (Ce 0.015 Lu 0.1 Gd 0.885 ) 3 (Al 0.5 Ga 0.5 ) 5 o 12 Accurately weigh the mass of each oxide, use absolute ethanol as the ball milling medium, and use polytetrafluoroethylene balls as the grinding balls. According to the mass ratio ball: material: absolute ethanol ≈ 6:1:1.2, mix the materials through a high-energy planetary ball mill, The ball milling speed is 300r / min, the ball milling time is 12h, the obtained slurry is dried in a blast drying oven at 60°C for 12h, and the obtained powder is treated at above 600°C for 2-4 hours to obtain a precursor powder.

[0099] (2) Weigh 100g of...

Embodiment 2

[0103] In this embodiment, a ball milling process, a thermal spraying process and a hot isostatic pressing process are combined to prepare lutetium aluminum garnet-based transparent ceramics. details as follows:

[0104] (1) Weigh 100g of the precursor powder obtained in step (1) of Example 1, and put it into the special nozzle hopper of thermal spraying equipment. The fuel gas uses hydrogen, and the powder rushes to the nozzle opening with the airflow. The powder is melted into micro-droplets at high temperature, and sprayed out at a high speed with a spray speed of 800m / s. The micro-droplets hit the pre-carrier sheet and spread into a layered material with a thickness of 1000μm, and the layered material is removed from the pre-carrier sheet And ground in an alumina crucible through a 200-mesh sieve to obtain the desired powder;

[0105] (2) Press the powder in the above step (1) into a disc with a diameter of 25mm in a steel mold and treat it with cold isostatic pressing at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com