An underpinning method for two-sided or three-sided wrapped reinforced concrete columns

A reinforced concrete column and wrapping technology, which is applied in the direction of building maintenance, construction, building construction, etc., can solve problems such as lack of construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

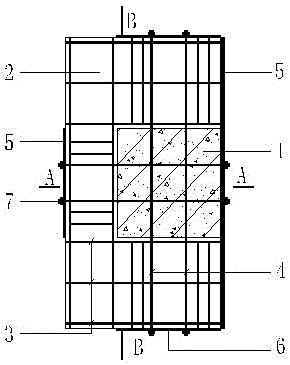

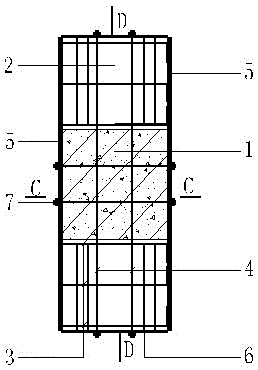

[0022] A method for underpinning a reinforced concrete column using two- or three-sided wrap-around technology, in which column-wrapped beams are poured on two or three sides of the underpinned reinforced concrete column (1), avoiding site constraints and completing the underpinning of the reinforced concrete column Change.

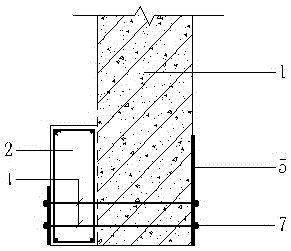

[0023] The method of pasting steel plates in a narrow space is used to realize the vertical load transmission on the side; the other sides adopt the conventional method of hugging and underpinning. The steel plate and the column-holding beam (2) are connected as a whole by adopting the method of welding the "["-shaped steel bar (3) on the steel plate. The method of passing the prestressed screw between the opposite side of the steel plate is adopted to increase the integrity of the entire underpinning node and improve the underpinning bearing capacity.

[0024] When the space on one side is narrow, an underpinning form of steel plates on one side and bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com