Embedded production monitoring system and monitoring method for concrete batching plant

A monitoring system and mixing station technology, applied in the field of embedded production monitoring systems, can solve problems such as monitoring blind spots, and achieve the effects of monitoring, low cost, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

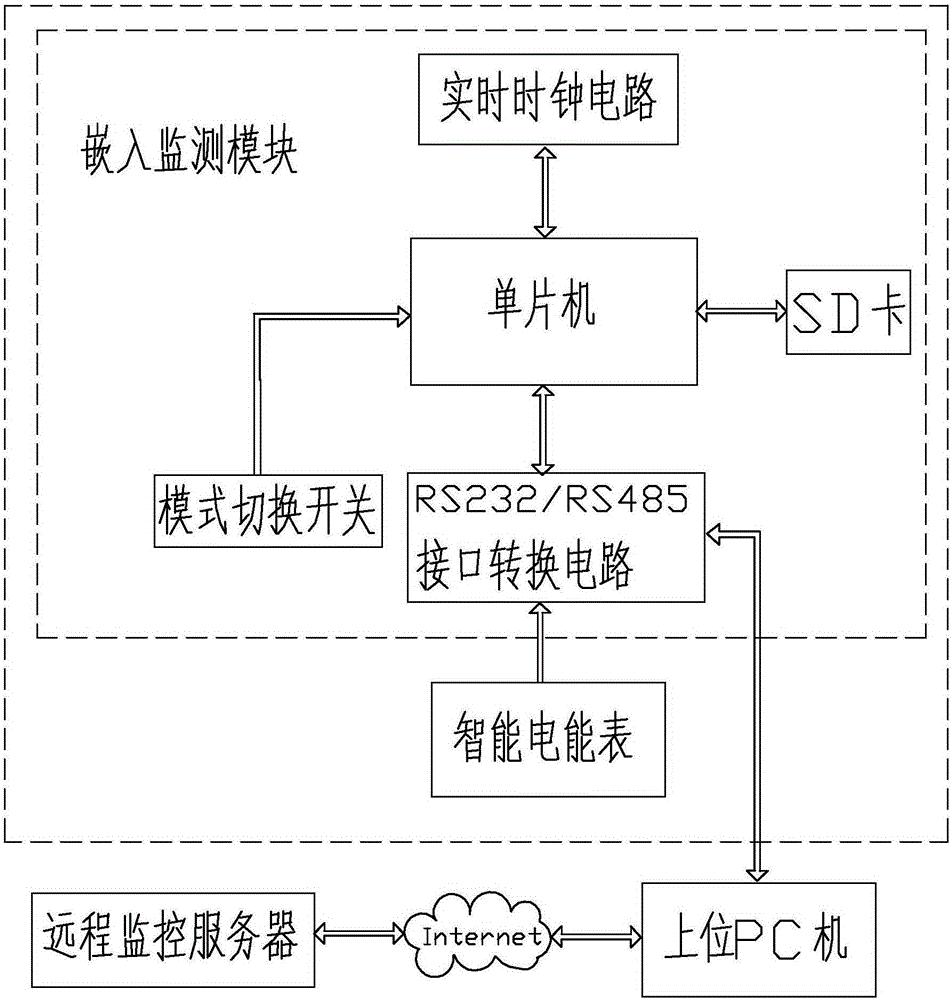

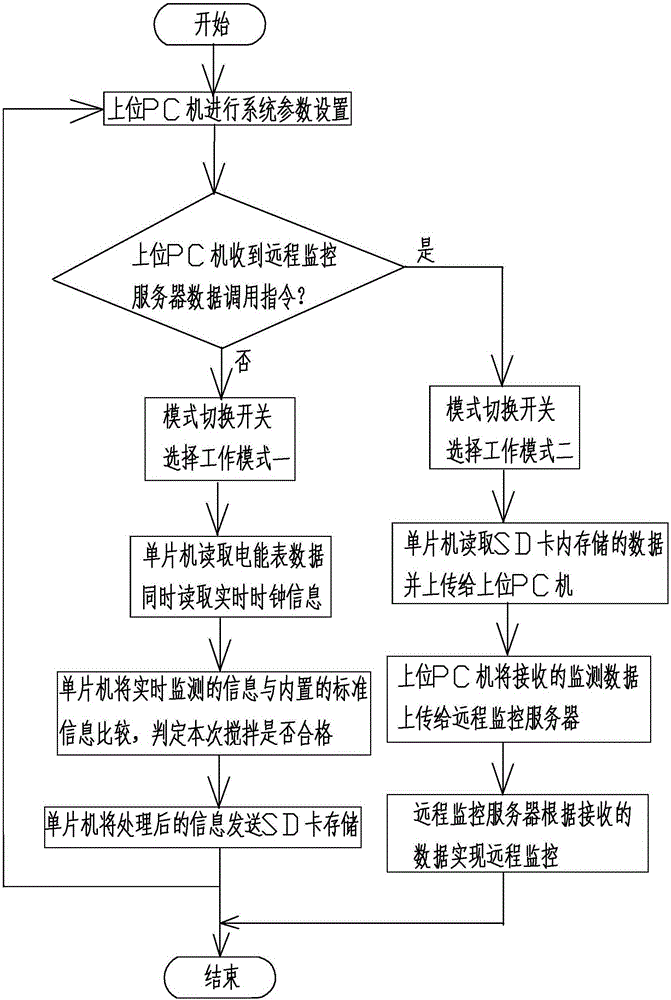

[0023] See figure 1 , The embedded production monitoring system of the concrete mixing plant in this embodiment is mainly composed of a smart electric energy meter, an embedded monitoring module, a mode switching switch, an upper PC and a remote monitoring server.

[0024] The smart electric energy meter is set on the dedicated line for powering the concrete mixer. The smart energy meter adopts a smart energy meter that supports RS232 full-duplex or RS485 half-duplex interface and follows the Modbus communication protocol. In this embodiment, the intelligent electric energy meter preferably adopts a model dh8a-nn2 intelligent electric energy meter produced by Zhongshan Mingying Electric Appliance Company. A special circuit board is added in the smart electric energy meter, and the circuit board is provided with working power by the intelligent electric energy meter.

[0025] The embedded monitoring module is arranged on a special circuit board added in the smart electric ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com