Stamping die of cellphone protective shell

A mobile phone protective case and stamping die technology, applied in the field of stamping die, can solve the problems of waste of labor cost and mechanical cost, short service life, poor drop resistance, etc., to reduce labor cost and mechanical cost, improve stability and efficiency, The effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

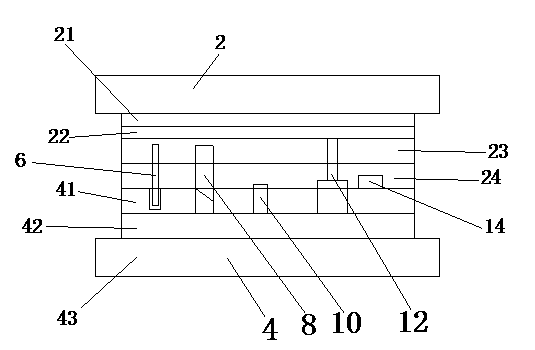

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 As shown, a stamping die of a mobile phone protective case of the present invention includes an upper die 2 and a lower die 4;

[0016] The upper mold 2 includes an upper mold base 21, an upper backing plate 22, an upper splint 23 and a stripper plate 24 in turn;

[0017] The lower die 4 includes a lower template 41, a lower backing plate 42 and a lower die base 43 in turn;

[0018] The stripping plate 24 is provided with a punching die 6, a bending die 8, a leveling die 10 and a bonding die 12 in sequence, so that the stamping die can complete multiple stamping processes at different positions of the workpiece in one stroke. , which greatly saves manpower, improves production efficiency, and has high stability.

[0019] The punching die 6 includes corresponding punches and blanking holes.

[0020] The bending die 8 includes c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com