Method for detecting alumite hot stamping performance

A detection method, anodized aluminum technology, applied in the direction of copying/marking method, general parts of printing machinery, printing, etc., can solve the problems of waste of anodized aluminum, poor hot stamping performance, etc., achieve simple detection method, save preparation time, Speed up the effect of parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

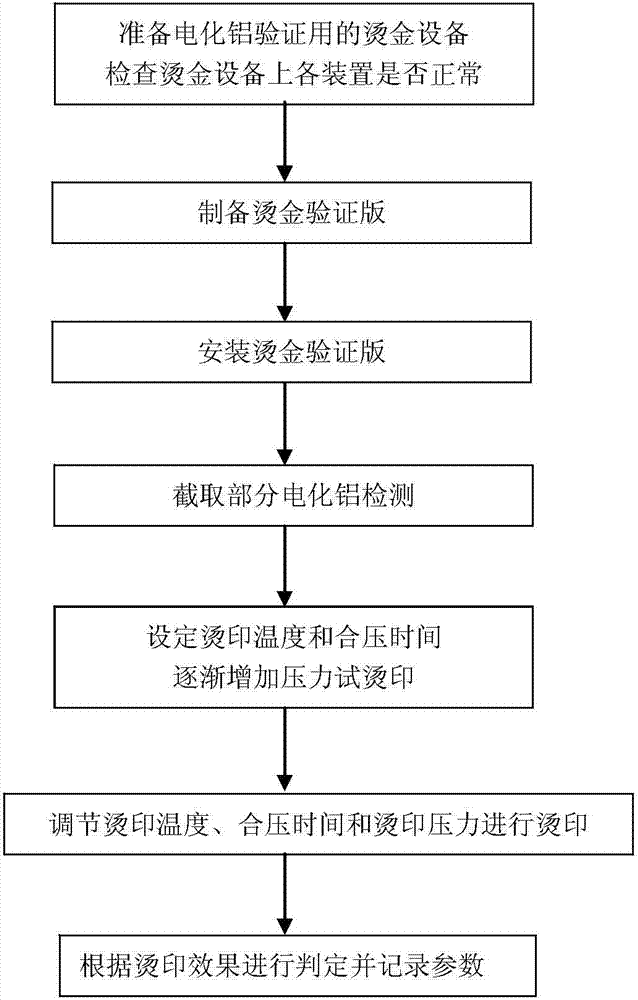

[0030] A method for detecting hot stamping performance of anodized aluminum comprises the following steps, and each step is specifically described.

[0031] S1. Prepare hot stamping equipment for anodized aluminum verification, check whether the temperature control sensor, pressure sensor and pressure closing time indication are normal, and check whether the electrical circuit and safety protection devices are normal.

[0032] S2. Prepare a bronzing verification plate with graphics. The bronzing verification plate is a red copper plate with a thickness of 1.5 mm, a length of 12 cm, and a width of 8 cm; wherein the graphic text on the bronzing verification plate is completed by computer-controlled micro-carving , the graphics and text include lines of different thicknesses and solid areas, the thickness of the lines includes 0.1mm lines, 0.25mm lines, 0.4mm lines and 0.5mm lines, and the spacing between adjacent lines includes 0.05 mm pitch, 0.08mm pitch, 0.15mm pitch, and 0.3m...

Embodiment 2

[0040] A method for detecting hot stamping performance of anodized aluminum comprises the following steps, and each step is specifically described.

[0041] S1. Prepare hot stamping equipment for anodized aluminum verification, check whether the temperature control sensor, pressure sensor and pressure closing time indication are normal, and check whether the electrical circuit and safety protection devices are normal.

[0042] S2. Prepare a bronzing verification plate with graphics. The bronzing verification plate is a brass plate with a thickness of 3.0mm, a length of 5cm, and a width of 5cm; wherein the graphics and texts on the bronzing verification plate are made by computer-controlled micro-carving Completed, the graphics and text include lines of different thicknesses and solid areas, the thickness of the lines includes lines of 0.6mm, 0.7mm, 0.9mm and 1.0mm, and the distance between adjacent lines includes 0.1mm spacing, 0.2mm spacing, 0.4mm spacing and 0.5mm spacing, t...

Embodiment 3

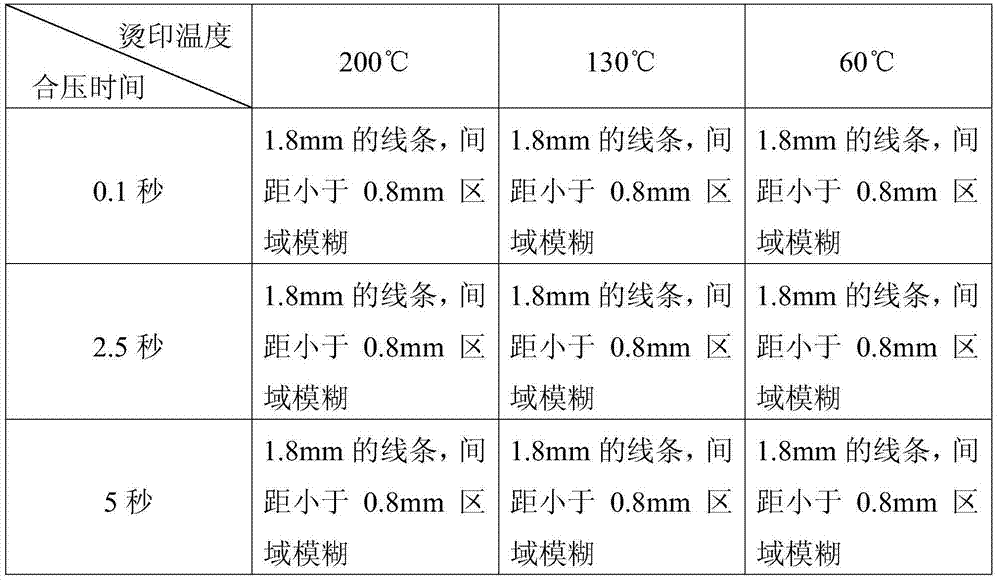

[0049] A method for detecting hot stamping performance of anodized aluminum comprises the following steps, and each step is specifically described.

[0050] S1. Prepare hot stamping equipment for anodized aluminum verification, check whether the temperature control sensor, pressure sensor and pressure closing time indication are normal, and check whether the electrical circuit and safety protection devices are normal.

[0051] S2. Prepare a bronzing verification plate with graphics. The bronzing verification plate is a steel plate with a thickness of 5.0 mm, a length of 15 cm, and a width of 15 cm; wherein the graphic text on the bronzing verification plate is completed by computer-controlled micro-carving , the graphics include lines of different thicknesses and solid areas, the thickness of the lines includes lines of 1.5mm, 1.65mm, 1.8mm and 2.0mm, and the distance between adjacent lines includes 0.5 mm pitch, 0.6mm pitch, 0.8mm pitch, and 1.0mm pitch.

[0052] S3. Install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com