A track for cranes running vertically and horizontally and interlacedly for hoisting components

A crane and longitudinal rail technology, applied in rail systems, load hanging components, transportation and packaging, etc., can solve the problems of many auxiliary transportation equipment, high transportation costs, and high labor intensity, saving transportation equipment and reducing labor intensity. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

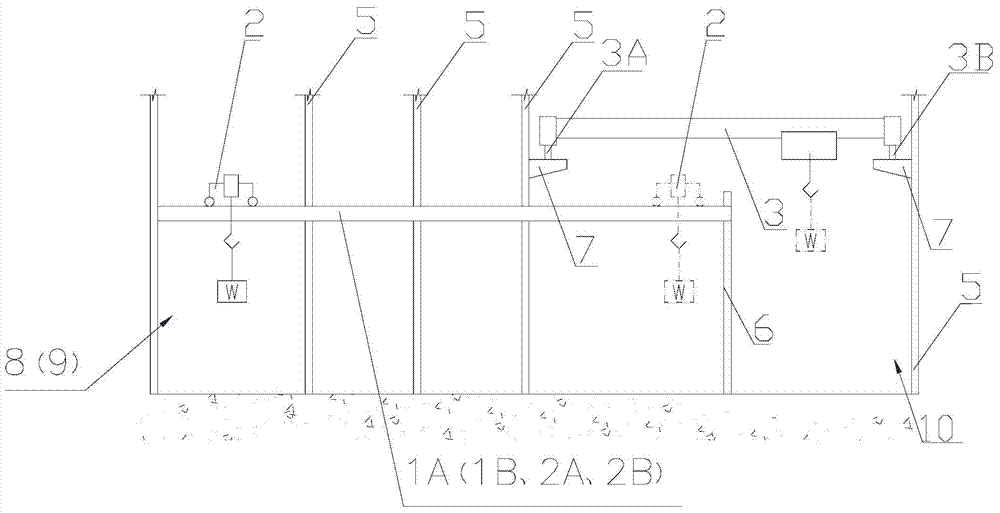

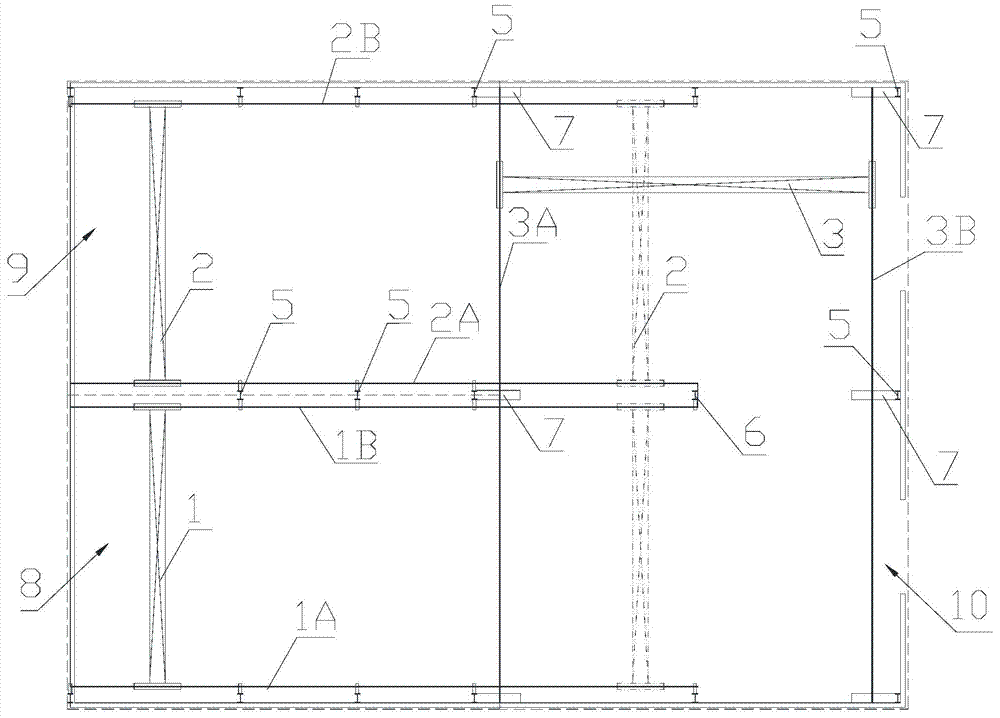

[0014] figure 1 is the front view of the present invention; figure 2 yes figure 1 top view.

[0015] As shown in the figure, the present invention provides a rail for cranes traveling vertically and horizontally to stagger hoisting components, and its structure includes: two parallel left longitudinal rails 3A and right longitudinal rails 3B for the operation of the third crane 3;

[0016] Two parallel first front transverse rails 1A and first rear transverse rail 1B constituting the operation of the first crane 1;

[0017] The first front transverse rail 1A and the first rear transverse rail 1B are lower than the left longitudinal rail 3A and the right longitudinal rail 3B, and the first front transverse rail 1A and the first rear transverse rail 1B are extended and inserted into two adjacent Parallel to the area between the left longitudinal rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com