Energy storage type miniature water head fluid energy pumping system

A technology of fluid energy and water head, which is applied in the direction of non-variable pumps, liquid variable-capacity machines, piston pumps, etc., can solve the problems of low pumping efficiency, waste of traditional energy, unrealistic problems, etc. Slow, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The present invention will be further described below in conjunction with the examples and accompanying drawings, because the following description is only a specific embodiment of the present invention, but the protection of the present invention is not limited thereto, and any changes or substitutions conceived by those skilled in the art are all covered within the protection scope of the present invention.

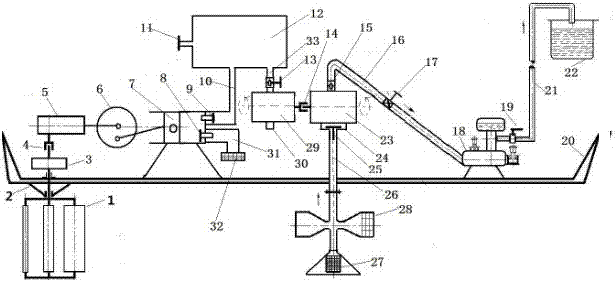

[0031] An energy storage type micro-head fluid energy pumping system, the system consists of a fluid energy harvesting mechanism (1), a speed change mechanism (5), a crank connecting rod mechanism (6), a plunger type air pump (7), an air storage tank (12), The pneumatic motor (30), the rotor type water pump (23), the water hammer pump (18) and pipelines, wherein the fluid energy harvesting mechanism (1) is connected with the speed change mechanism (5), and the speed change mechanism (5) passes through the crank connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com