Stepless speed change device

A continuously variable transmission, helical gear technology, applied in transmission, gear transmission, belt/chain/gear, etc., can solve the problems of simple and reliable structure, difficult structure, complicated structure of manual transmission and automatic transmission, etc. To achieve the effect of large torque, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

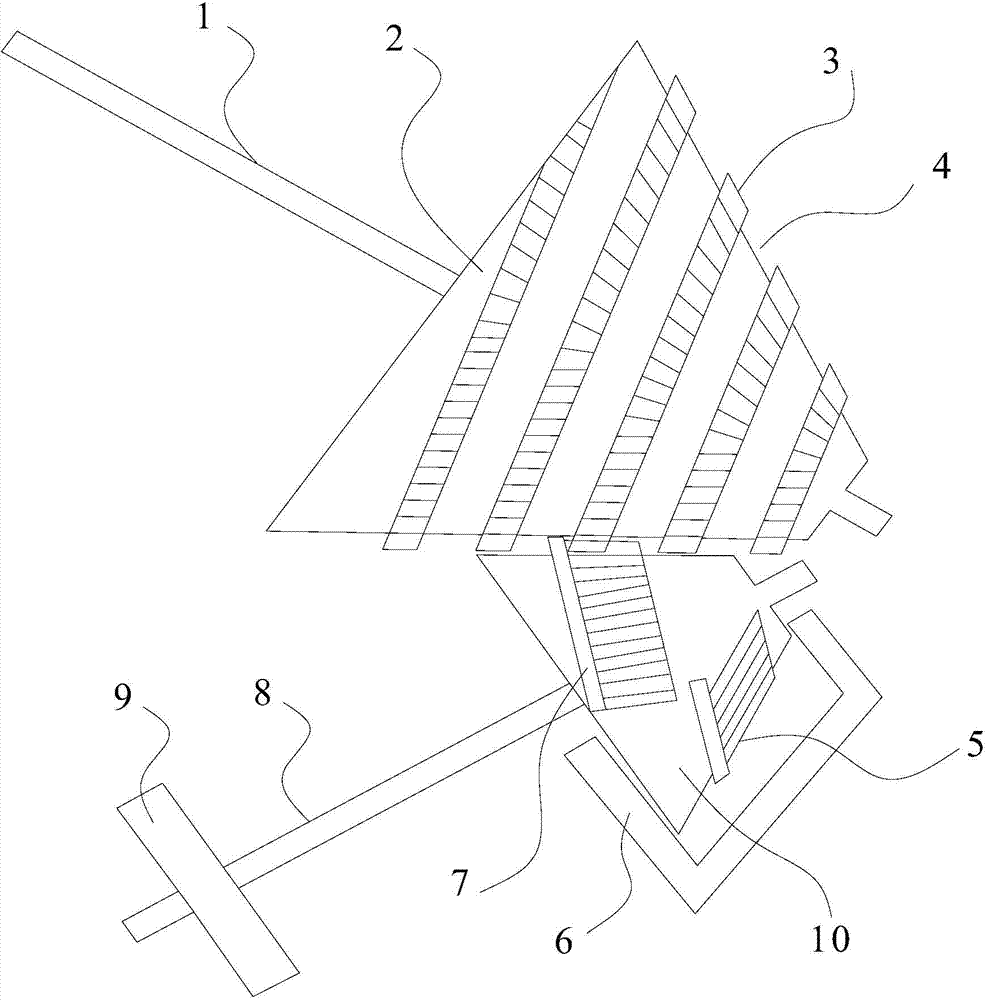

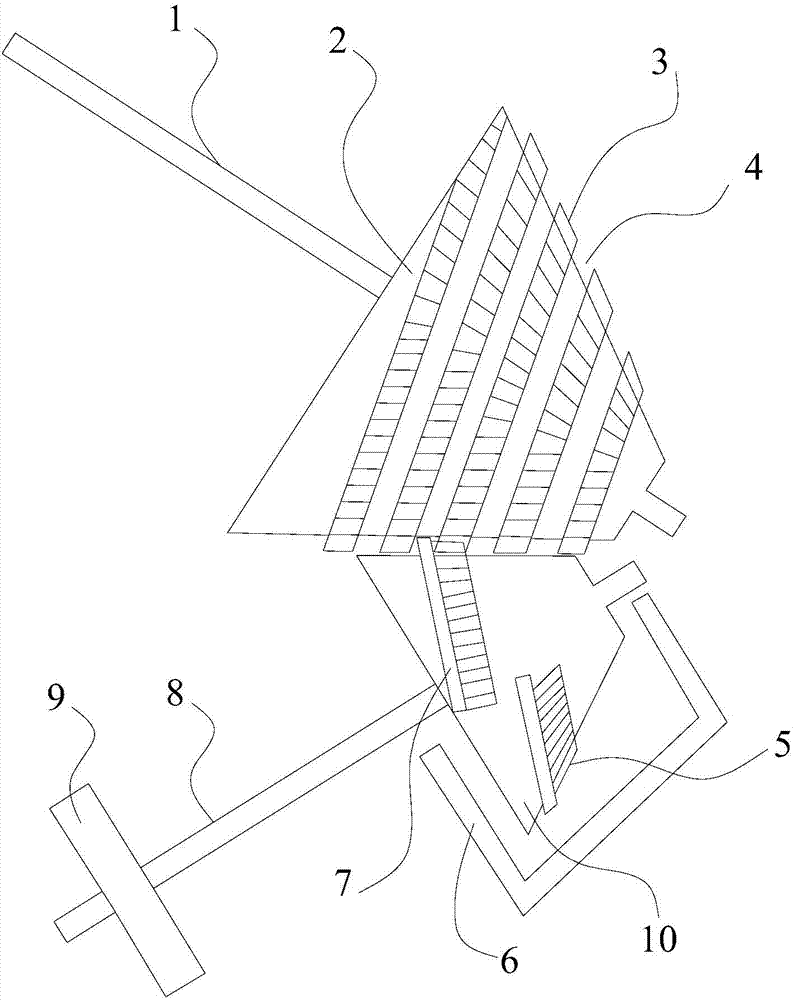

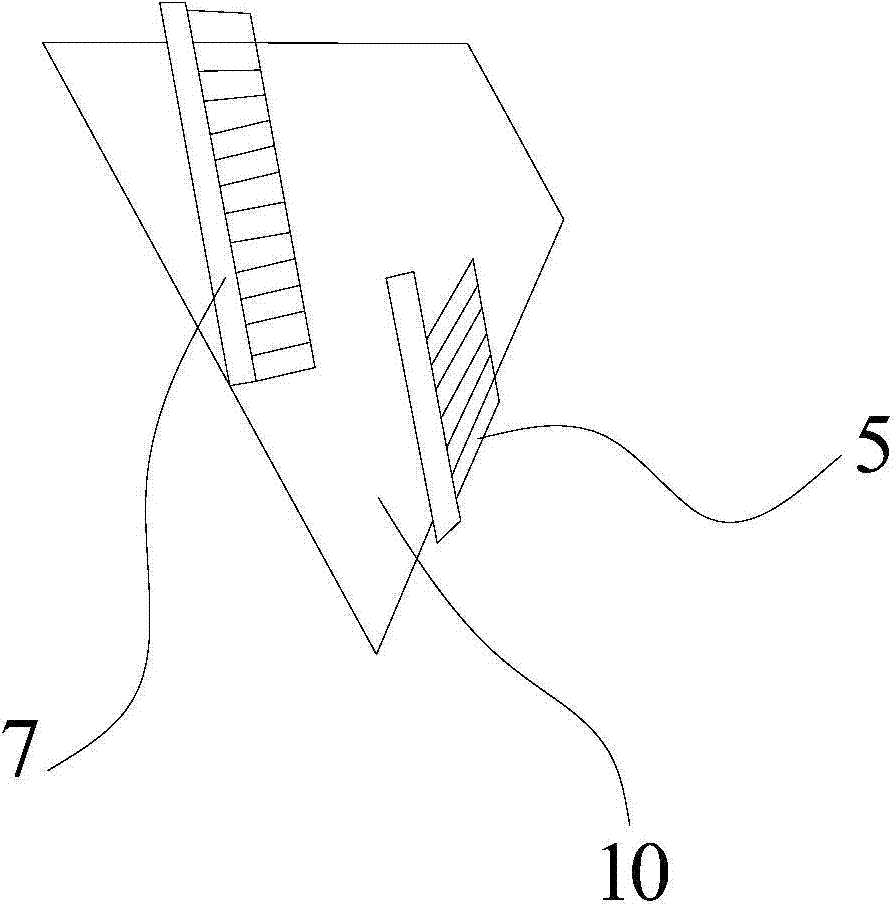

[0012] Such as figure 1 , figure 2 , image 3 with Figure 4 Shown is a continuously variable transmission device provided by this embodiment, including an input shaft 1, an input helical gear, an output shaft 8 and an output helical gear; the input helical gear includes an input cone 2 and an input tooth 3; the input cone 2 and the The input shaft 1 is rotationally connected; the input teeth 3 are spirally arranged in multiple turns on the outer circumferential surface of the input cone 2 along its axis; the pitch of the input teeth 3 in each turn is equal, and the number of teeth of the multi-turn input teeth increases proportionally in integer multiples; The output helical gear comprises an output cone 10 and an output tooth 5; the output cone 10 can slide along the output shaft 8 and transmit torque to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com