A Fast and Rigorous Simulation Method for the Diffraction Spectrum of a Defect-Free Mask in Extreme Ultraviolet Lithography

A technology of extreme ultraviolet light and simulation method, which is applied in the direction of microlithography exposure equipment, photolithography exposure equipment, instruments, etc., and can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the examples and drawings, but the examples should not limit the protection scope of the present invention.

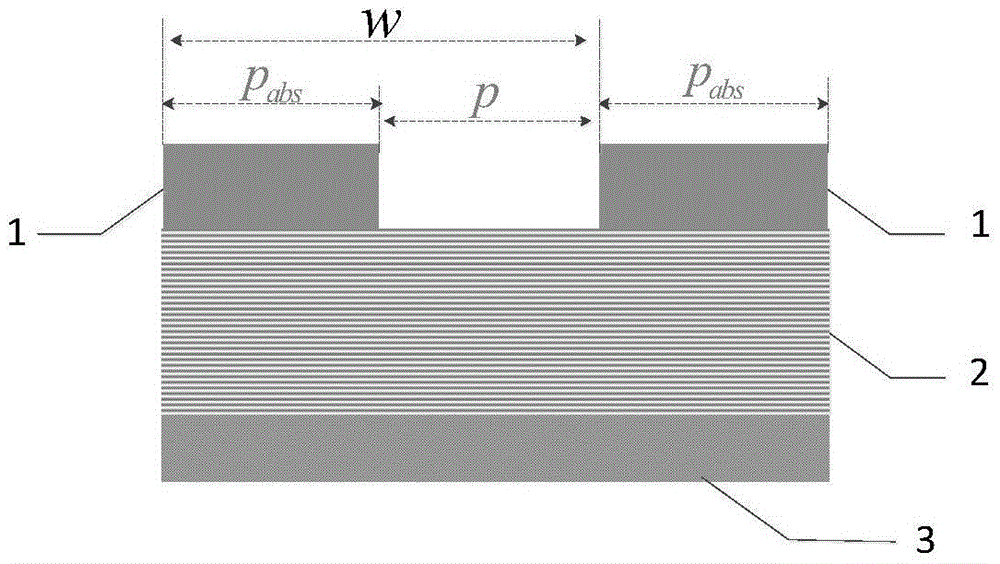

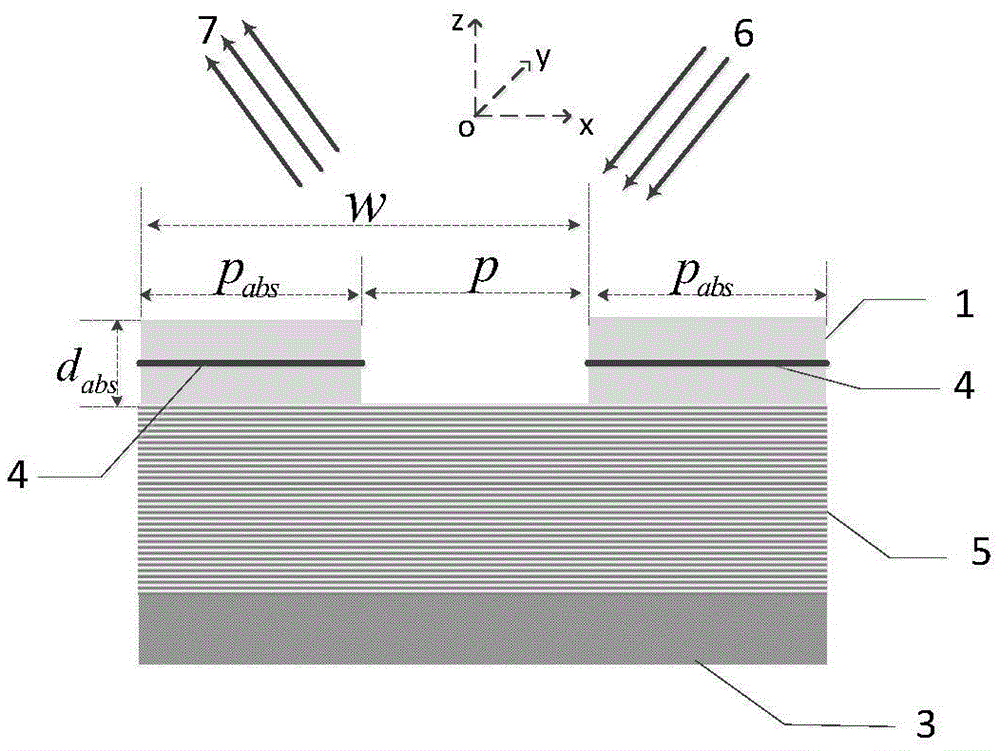

[0053] see first figure 1 , figure 1 It is a schematic diagram of the basic structure of the EUV lithography defect-free mask used in the present invention, mainly including a mask absorption layer 1, a multilayer film 2 and a substrate 3, and the obtained defect-free mask model is as follows figure 2 As shown, the absorbing layer is modeled by the equivalent thin mask model 4, and the multilayer film is modeled by the equivalent film layer method model 5.

[0054] The specific steps of the simulation method include:

[0055] (1) Simulation mask absorption layer diffraction spectrum:

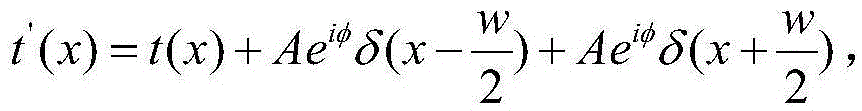

[0056] The approximate complex transmission coefficient of the equivalent thin mask model 4 is:

[0057] t ′ ( x ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com