High-power LED high-voltage constant-current driving module

A driving module and high-voltage technology, which is applied to the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of scrapping the entire light bar, increasing production and repair costs, and damage to LED Zener diodes, so as to reduce LED Packaging cost, improving LED packaging yield, and realizing the effect of generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

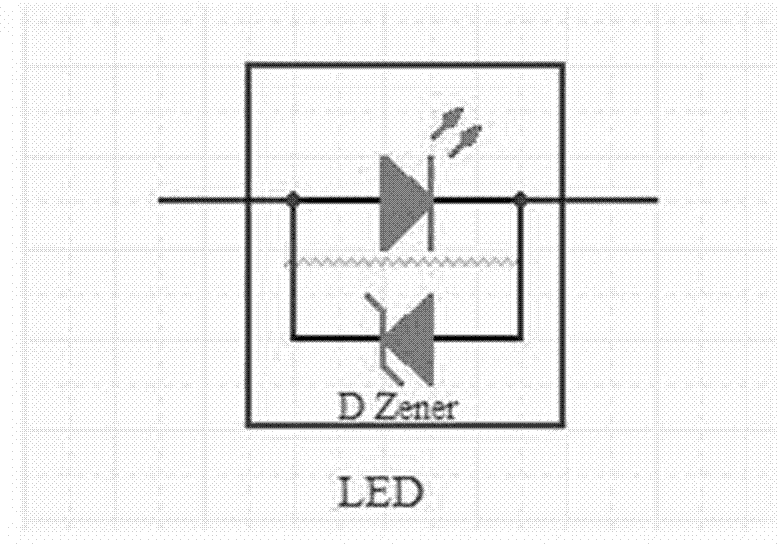

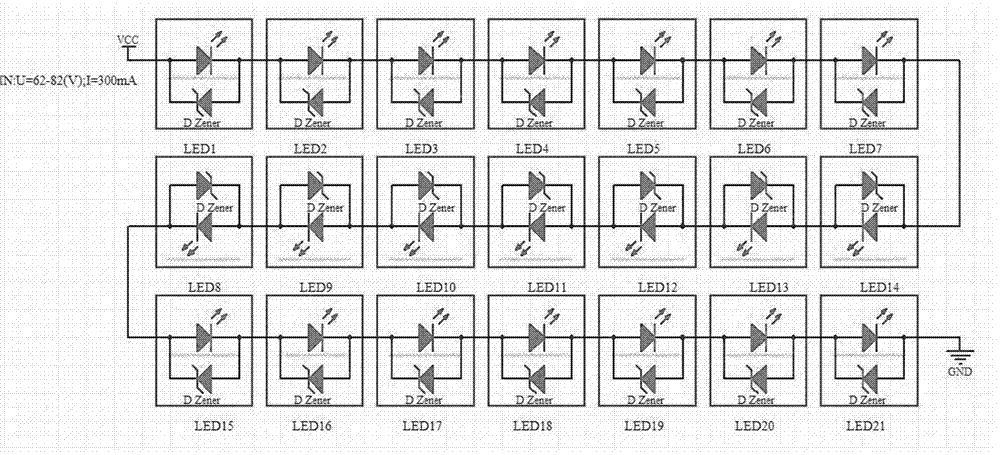

[0028] A high-power LED high-voltage constant-current drive module, including a plurality of parallel-connected single light bars, the single light bar is composed of several LED lights in series; the several LED lights of each single light bar are connected with an external After the nanodiode is connected in parallel, it is connected in series with an independent driving module. The voltage of the independent driving module is 22-26 volts, and the maximum passing current is 300mA.

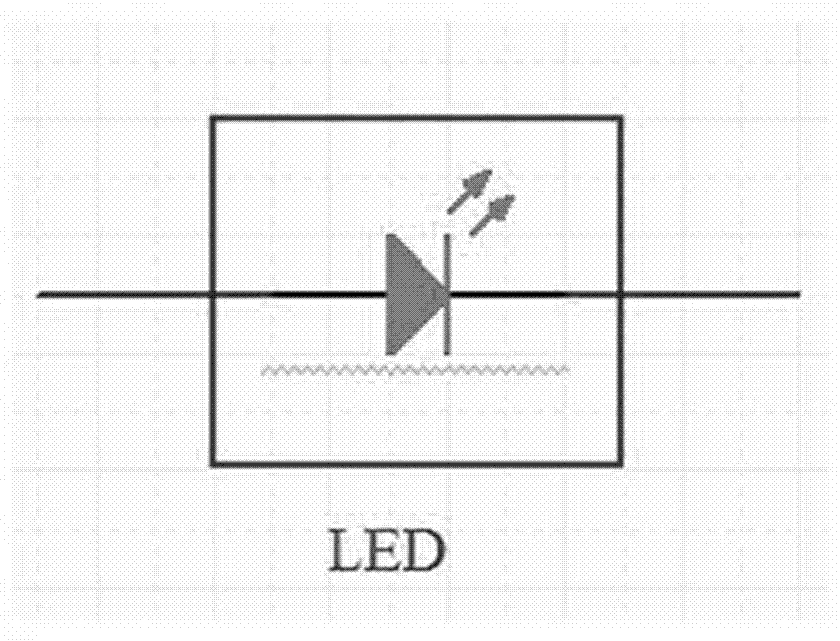

[0029] Implementation of external anti-ESD zener diode: remove the zener diode used in the packaging process of medium and high power LEDs, such as figure 2 , duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com