Direct injection type exquisite closestool with front-arranged siphon

A siphon and toilet technology, which is applied in water supply devices, flushing toilets, buildings, etc., can solve the problems of not paying attention to the release of water pressure potential energy in the toilet flow channel system, and the washing force is small, so as to achieve the saving of raw material consumption, the simplicity of the module, and the reduction in size. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

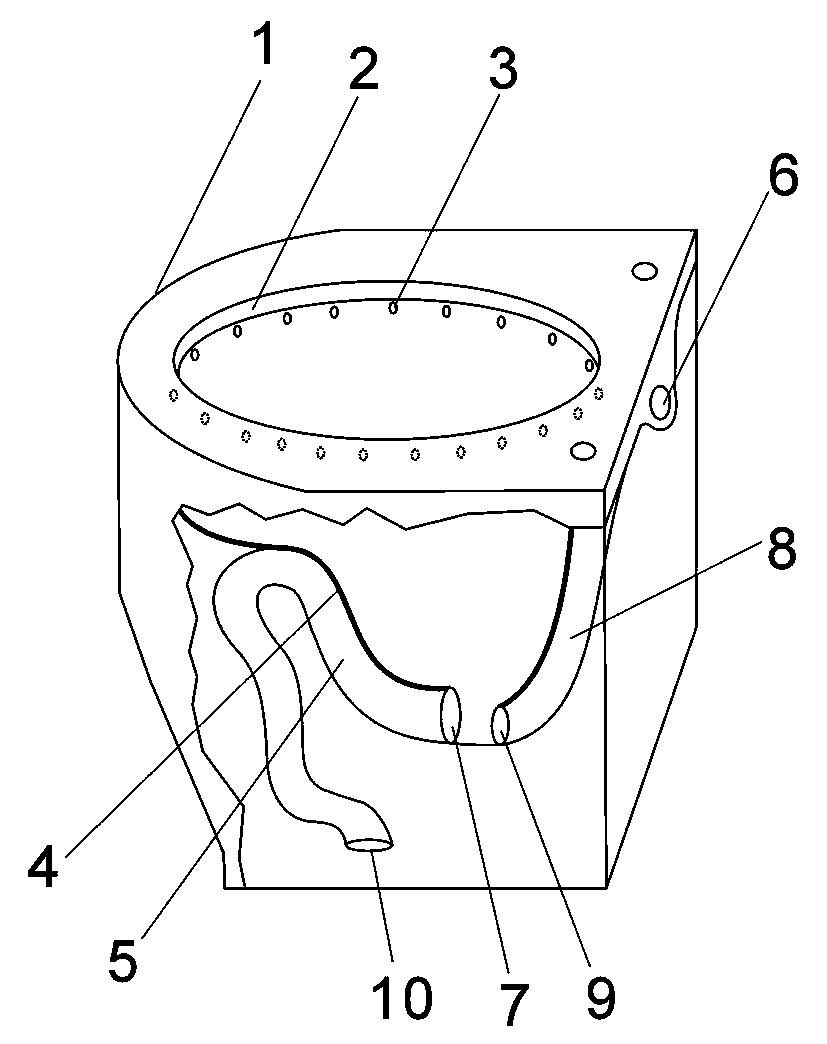

[0019] figure 1 The specific implementation manner of the Linglong toilet with direct injection front siphon of the present invention is shown. The water guiding ring 2 structure is on the upper edge of the toilet main body 1, and the lower edge of the water guiding ring 2 is distributed with a scrubbing hole 3. Below the scrubbing hole 3 is a bedpan bottom 4, and a siphon tube 5 is arranged at the front end under the bedpan bottom 4. Jet hole 9 is established on the opposite side of the bottom sewage pipe inlet 7, and siphon 5 follows the bottom of the bedpan 4 front ends to the sewage outlet 10, and water inlet 6 communicates with water guide ring 2 and jet pipe 8.

[0020] When starting flushing, because the pipeline of the whole runner system is all very short, the water in the water tank makes the spray pipe 8 be full of water immediately by the water inlet 6, and the spray hole 9 starts to spray the sewage pipe inlet 7, and like this, the siphon pipe 5 forms immediately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com