Fastener

A technology of fixing parts and cylinders, applied in the direction of connecting members, pins, mechanical equipment, etc., can solve the problems of large space, cumbersome, and weakening the heat dissipation function of the radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

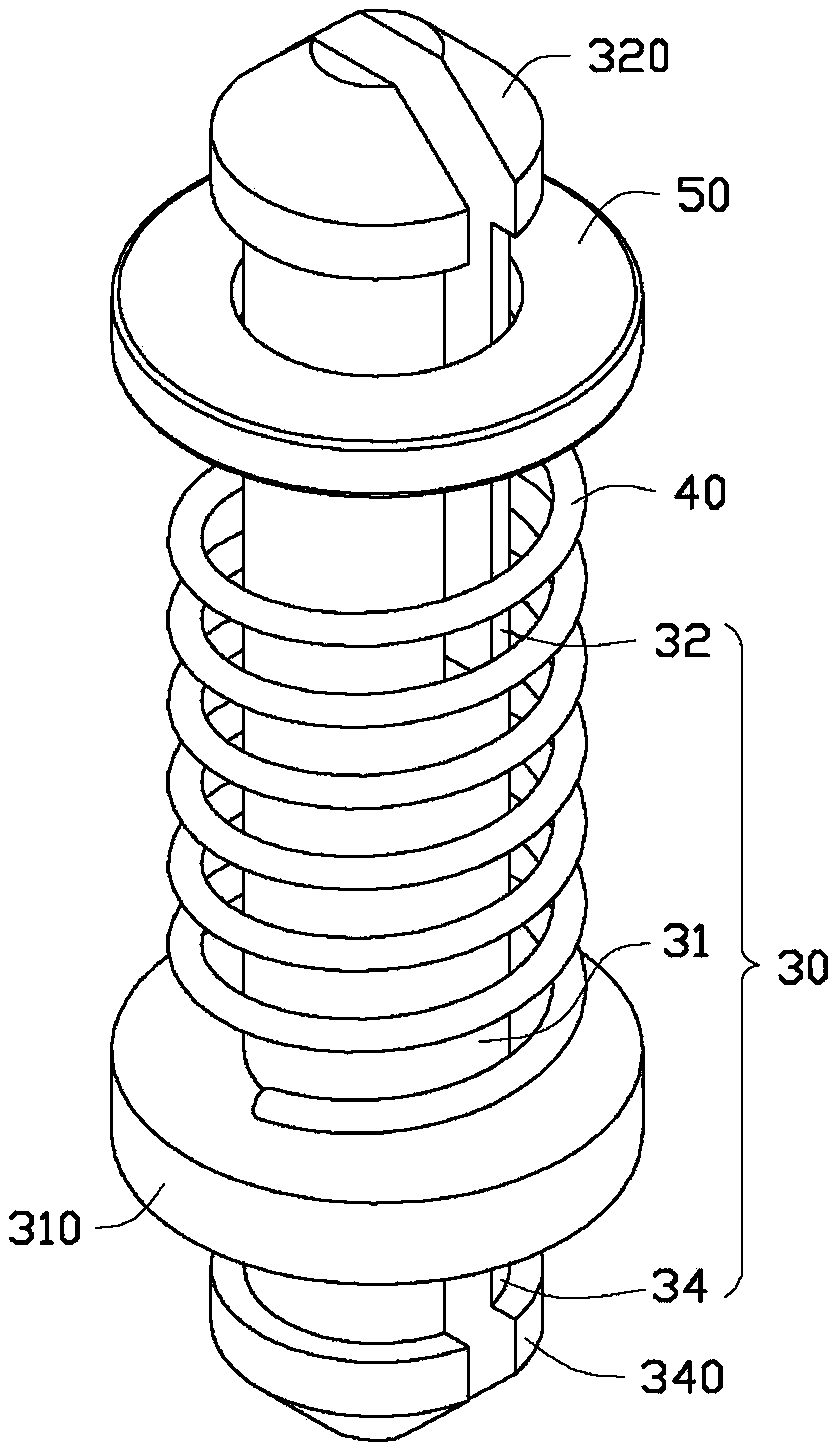

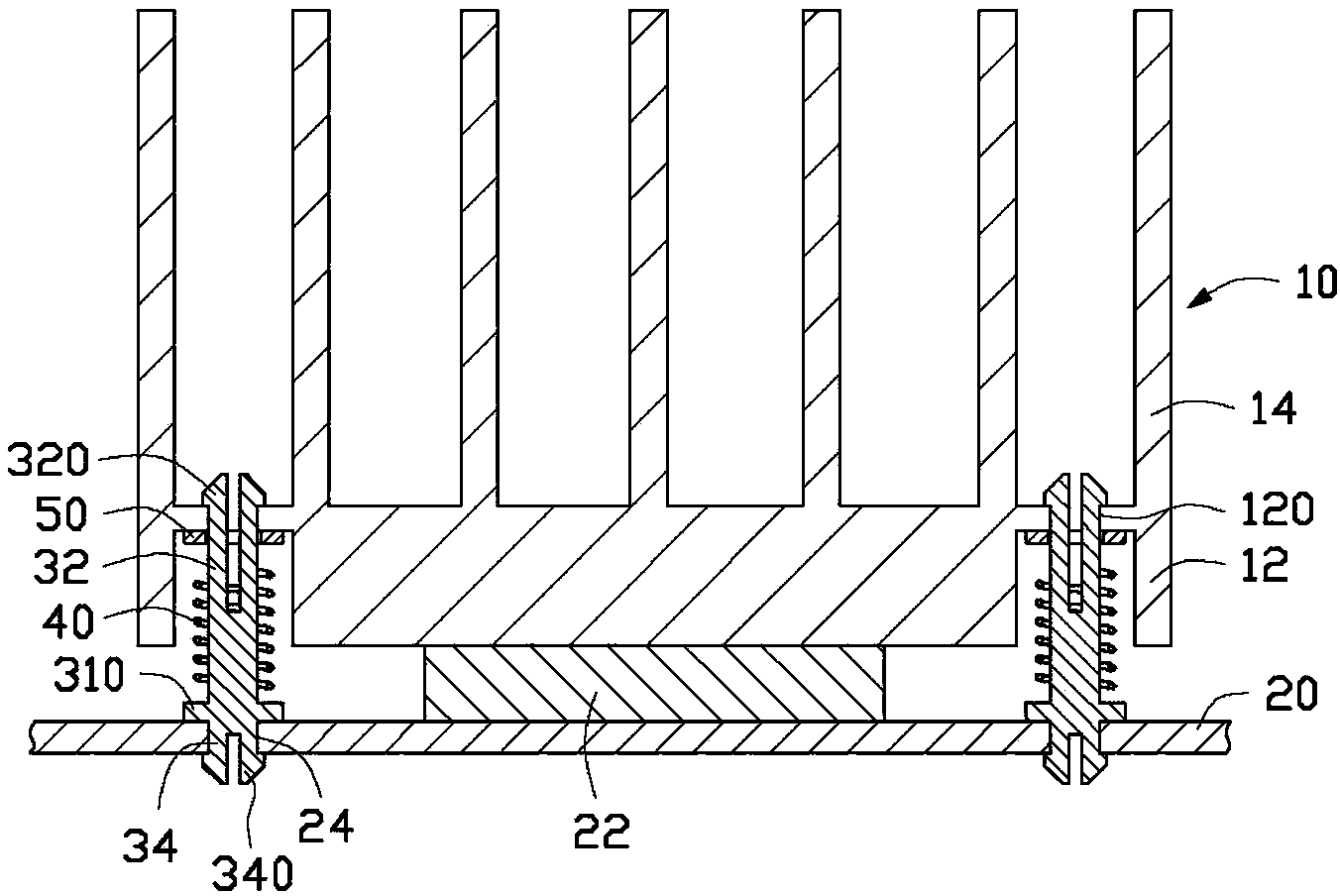

[0011] Please refer to figure 1 and figure 2 , the fixing member of the present invention is used to fix a radiator 10 on a motherboard 20 . An electronic component 22 is disposed on the motherboard 20 . The motherboard 20 defines at least one through hole 24 on two sides of the electronic component 22 respectively.

[0012] The heat sink 10 includes a bottom plate 12 and a plurality of cooling fins 14 vertically extending upward from a top surface of the bottom plate 12 . The bottom plate 12 defines at least two through holes 120 corresponding to the through holes 24 of the main board 20 .

[0013] The fixing member includes a body 30 , a spring 40 and a washer 50 . The main body 30 includes a cylinder 31 , two parallel buckles 32 disposed on the top of the cylinder 31 , and two parallel locking feet 34 disposed on the bottom of the cylinder 31 . Half-conical locking teeth 320 respectively protrude from the ends of the two buckles 32 . Two semi-conical protrusions 340 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com