Harmonic reducer of electric bicycle driver

A technology of harmonic reducer and electric bicycle, applied in the direction of rider drive, transmission device, vehicle parts, etc., to avoid breakage, ensure riding safety, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

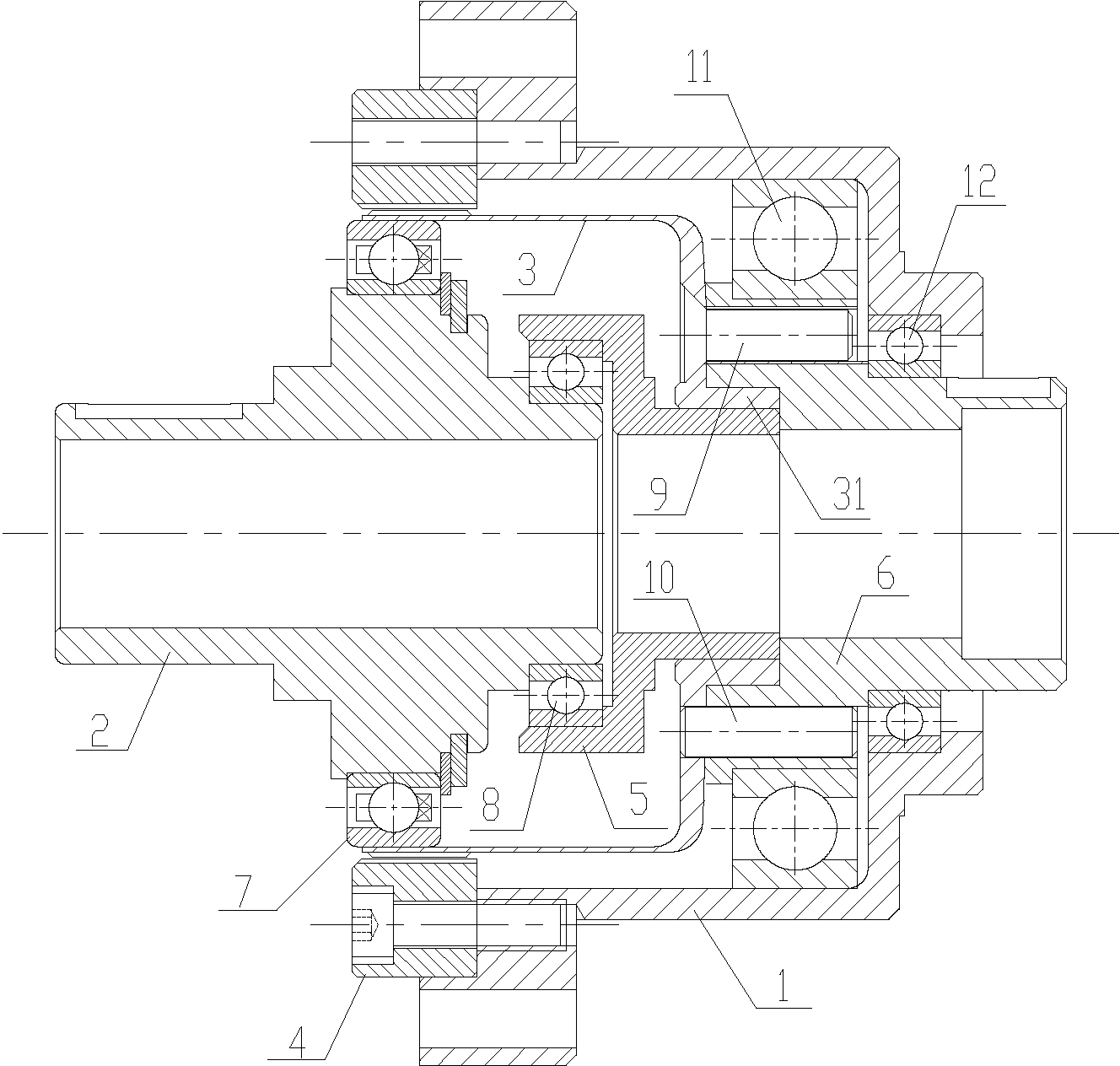

[0011] Such as figure 1 As shown, the harmonic speed reducer of the electric bicycle driver of the present invention includes a housing 1, a harmonic generator 2, a flexible spline sleeve 5, a harmonic flexible spline 3 and a harmonic rigid spline 4, the harmonic generator 2, the flexible spline The axle sleeve 5 and the harmonic flexible spline 3 are sequentially socketed and located in the housing 1, one end of the harmonic flexible spline 3 is arranged on the outer ring of the harmonic generator 2 through a bearing 7, and the harmonic rigid spline 4 is fixed on the inner ring of the housing 1 and is located on the outer ring at one end of the harmonic flexspline 3, and the inner ring at one end of the flexspline shaft sleeve 5 is arranged on the outer ring at one end of the harmonic generator 2 through a bearing 8, so The other end of the flexspline bushing 5 is set on the inner ring of the 3-axis diameter section 31 of the harmonic flexspline. This harmonic reducer also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com