Seedling cultivation plate

A technology for planting boards and seedlings, applied in the field of agricultural facilities, can solve the problems of reducing the work efficiency of garden workers, increasing the workload and complexity of garden workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

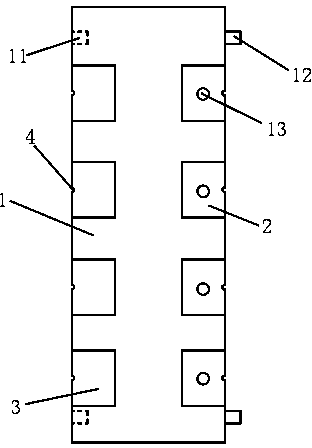

[0023] As shown in the attached picture,

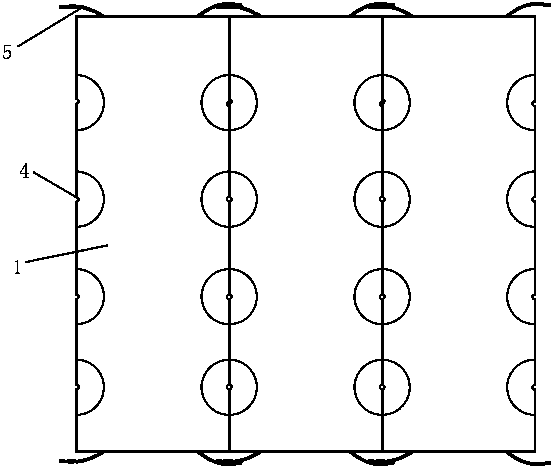

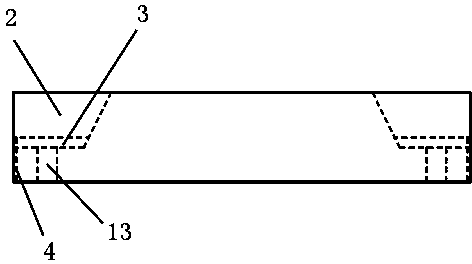

[0024] As shown in the accompanying drawings, a kind of seed cultivation board includes several veneers 1 spliced in sequence, and the two sides of the board body are symmetrically provided with several planting grooves 2 formed by depressions, and the bottom of the planting grooves 2 is provided with a removable Bottom plate 3, one side of the veneer 1 is provided with a slot 11, and the other side is provided with an insert 12, the insert 12 is inserted into the slot 11 on the adjacent veneer 1, the bottom of the planting groove 2 A push-up hole 13 is provided. The bottom plate 3 has the same shape and size as the planting groove 2 . The planting groove 2 and the bottom plate 3 are provided with through holes 4 communicating with each other. The slots 11 and the insertion strips 12 are respectively arranged at the upper and lower ends of the two sides of the single board 1 .

[0025] The groove wall of the planting groove 2 is ...

Embodiment 2

[0028] The difference from the above embodiment is that the planting groove 2 is a semicircular groove. The distance between the symmetrical planting grooves 2 on both sides of the veneer 1 is 30 cm. The aperture of push-up hole 13 is 4cm.

Embodiment 3

[0030] The difference from the above embodiment is that the distance between the symmetrical planting grooves 2 on both sides of the veneer 1 is 15 cm. The aperture of push-up hole 13 is 3cm.

[0031] When using, put the bottom plate in the planting tank, and then cover it with soil for seed cultivation. When you need to take out the seedlings, you can take it directly from the veneer or take out the bottom plate directly from the bottom plate. Due to long-term use, the bottom plate may not be easy to remove. The bottom plate can be pushed up from the bottom of the bottom plate through the push-up hole, and the through hole is used for drainage. The locking structure can reinforce the veneers to prevent the veneers from collapsing due to external forces during cultivation and transportation. When the veneer is used, multiple pieces are spliced, which is convenient for batch seedling cultivation. The board body can be disassembled when taking seedlings, which is convenient to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com