Platform for 3D (three dimensional) printer and 3D printer formed by platform

A 3D printer and platform technology, applied in the field of 3D printing, can solve problems such as large drive load, occurrence of problems, and multiple drive energies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described below in conjunction with the accompanying drawings. Apparently, the accompanying drawings describe only a part of the present invention rather than all embodiments.

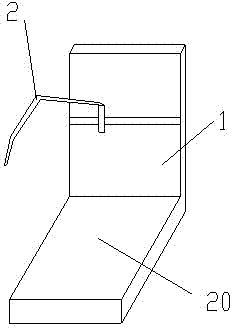

[0026] Such as figure 1 As shown, a 3D printer platform provided by the present invention includes a support 1 and a workbench 20 fixed on the support 1 , and a nozzle grabbing device 2 is connected to the support 1 . The grasping device 2 is used to grasp a plurality of printheads 4 fixed on the bracket 1 in the printhead magazine 3 , or the printheads 4 placed in the printhead magazine 3 on one side of the printer platform. For the latter, a movable print head library 3 can serve multiple printer platforms.

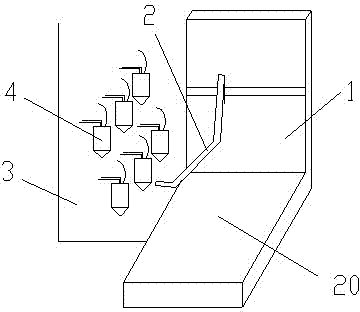

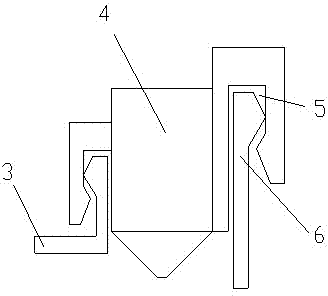

[0027] Such as figure 2 As shown, a 3D printer provided by the present invention includes a bracket 1, a nozzle 4 grasping device 2 fixed on the bracket 1, and a nozzle library 3, and a plurality of independent nozzles 4 are fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap