Reflective membrane with anti-counterfeiting mark, manufacture method of reflective membrane and anti-counterfeiting license plate

A technology of anti-counterfeiting marks and manufacturing methods, which is applied in the field of anti-counterfeiting marks and can solve problems such as cumbersome operations and restrictions on popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

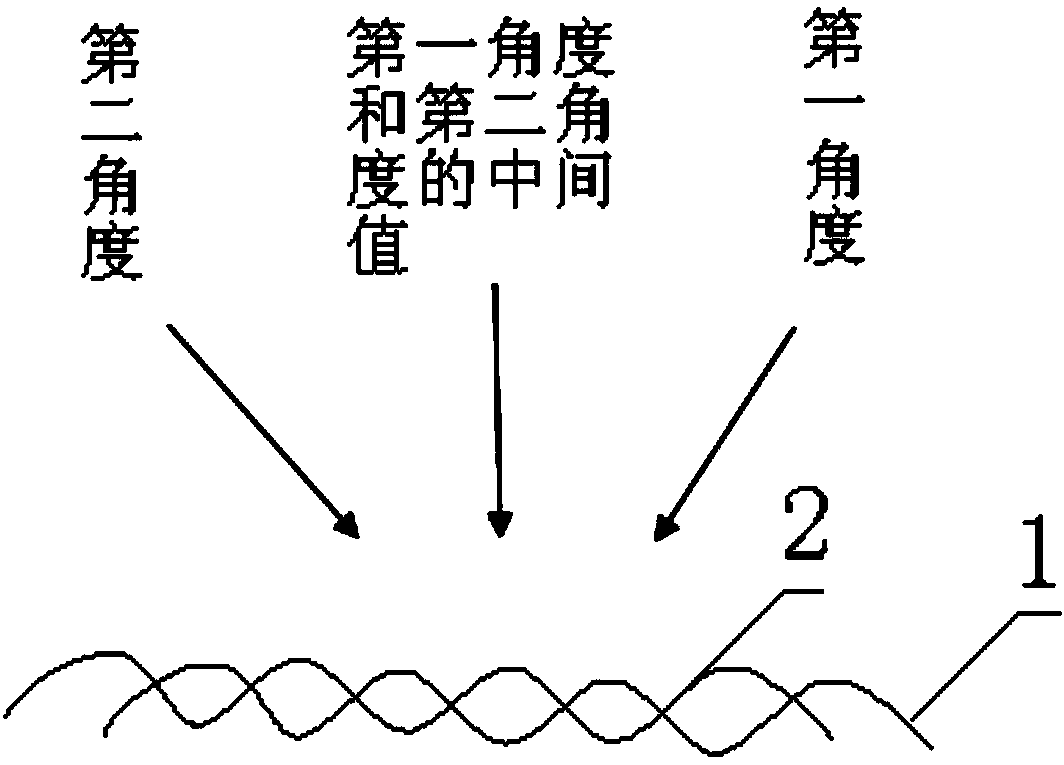

[0041] Fix the reflective film on the fixed platform, and lift the fixed platform to an appropriate position; design the anti-counterfeiting logo artwork in the laser marking system; adjust the position of the laser beam so that the laser beam and the reflective surface of the reflective film The included angle is 1°, the power of the laser beam is set to 2.8w, and the laser beam is used to print the first anti-counterfeiting mark on the reflective surface of the reflective film; the position of the laser beam is adjusted so that the laser beam and the reflective surface of the reflective film The included angle is negative 1°, the power of the laser beam is set to 2.8w, and the laser beam is used to print the second anti-counterfeiting mark on the reflective surface of the reflective film.

[0042] The obtained reflective film is between the first angle (the angle between the laser beam and the reflective surface of the reflective film is 1°) and the second angle (the angle be...

Embodiment 2

[0044] Fix the reflective film on the fixed platform, and lift the fixed platform to an appropriate position; design the anti-counterfeiting logo artwork in the laser marking system; adjust the position of the laser beam so that the laser beam and the reflective surface of the reflective film The included angle is 60°, the power of the laser beam is set to be 0.2w, and the laser beam is used to print the first anti-counterfeiting mark on the reflective surface of the reflective film; the position of the laser beam is adjusted so that the laser beam and the reflective surface of the reflective film The included angle is negative 60°, the power of the laser beam is set to 0.2w, and the laser beam is used to print the second anti-counterfeiting mark on the reflective surface of the reflective film.

[0045] The obtained reflective film is between the first angle (the angle between the laser beam and the reflective surface of the reflective film is 1°) and the second angle (the ang...

Embodiment 3

[0047] Fix the reflective film on the fixed platform, and lift the fixed platform to an appropriate position; design the anti-counterfeiting logo artwork in the laser marking system; adjust the position of the laser beam so that the laser beam and the reflective surface of the reflective film The included angle is 30 °, the power of the laser beam is set to be 2w, and the laser beam is used to print the first anti-counterfeiting mark on the reflective surface of the reflective film; the position of the laser beam is adjusted so that the laser beam is in contact with the reflective surface of the reflective film. The included angle is negative 30°, the power of the laser beam is set to 2w, and the laser beam is used to print the second anti-counterfeiting mark on the reflective surface of the reflective film. The obtained reflective film is covered on the base plate of the license plate to manufacture the anti-counterfeit license plate. As can be imagined by those skilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com