Height control method, device and system for hoisting hook of tower crane and tower crane

A hook and height technology, applied in the height control of the hoisting hook of a tower crane, in the field of tower cranes, can solve the problems of property loss, detection error of the height of the hoisting hook, casualties, etc., to achieve accurate determination results and improve accuracy effect of enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

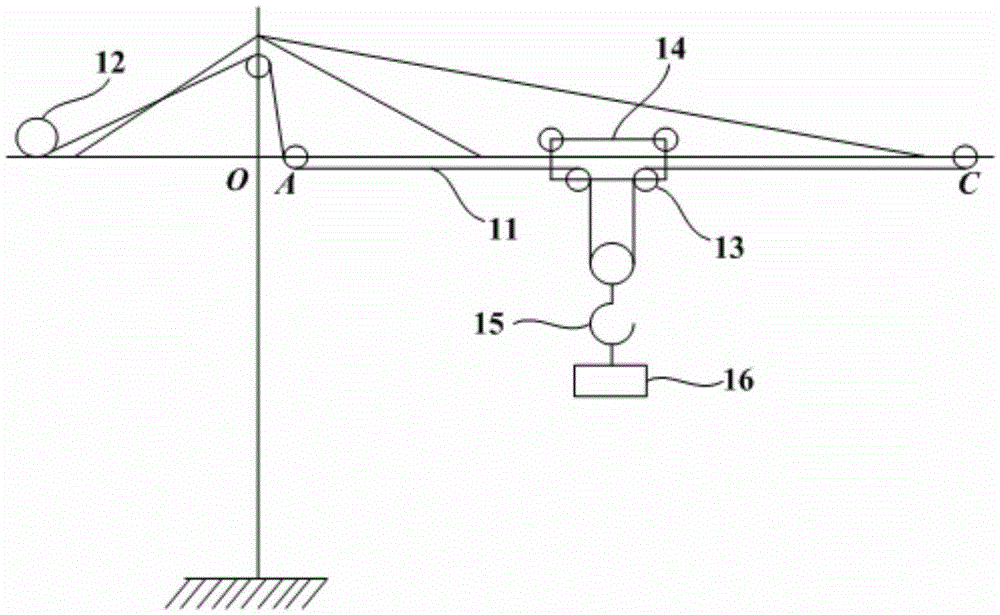

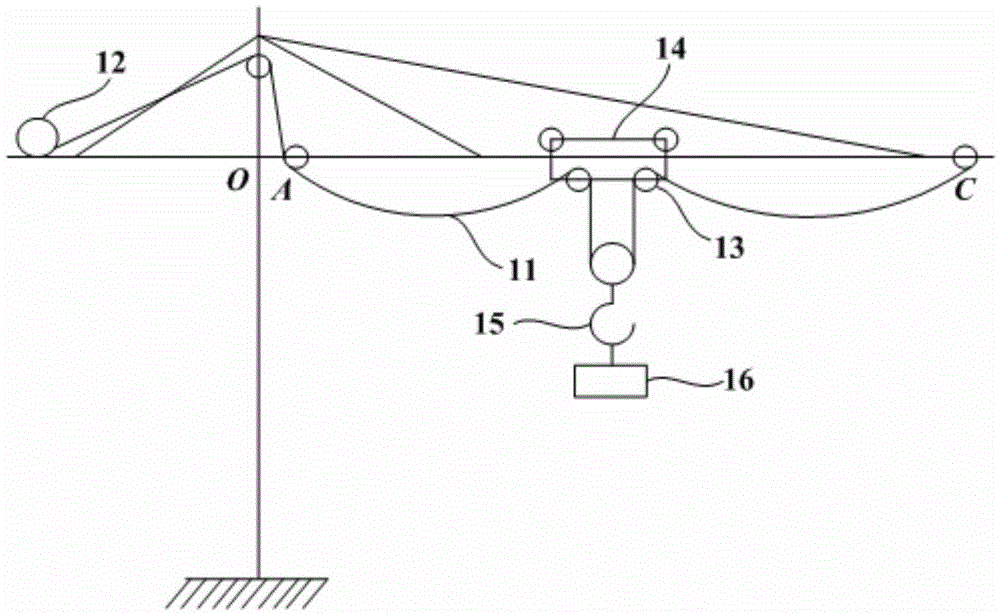

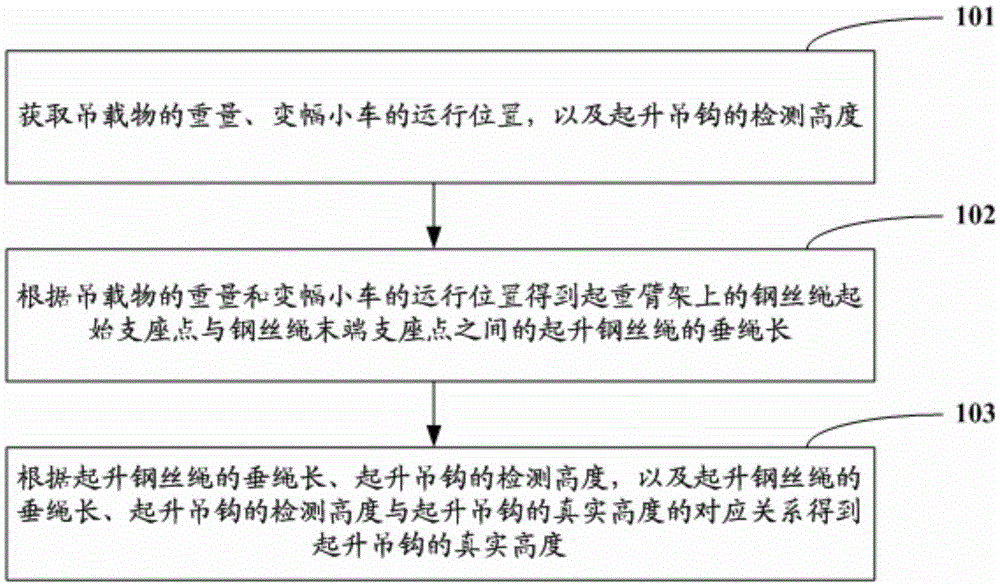

[0052] In order to improve the accuracy of determining the height of the hoisting hook, further improve the accuracy of the height limit of the hoisting hook, and improve the safety of the tower crane hoisting operation, the embodiment of the present invention provides a hoisting hook of the tower crane A height control method, device, system and a tower crane. In this technical solution, when the weight of the hoisted object and / or the operating position of the luffing trolley are different, the length of the vertical rope of the hoisting wire rope is also different. The detection height, and the length of the vertical rope of the lifting wire rope, the detection height of the lifting hook and the corresponding relationship between the real height of the lifting hook can be used to obtain the real height of the lifting hook. The determination result of the real height of the lifting hook is relatively Accurate, can greatly improve the accuracy of the height limit of the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com