Natural rubber sponge with high compression load retention rate and preparation method thereof

A natural rubber, high-compression technology, applied in the field of natural rubber sponge and its preparation, can solve the problems of difficult to meet the use requirements of precision instruments, large compression set, low load retention rate, etc., and achieves good appearance, high compression recovery rate, Uniform and consistent effect of internal cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of high load retention rate natural rubber sponge of the present invention is characterized in that comprising the following steps:

[0044] a. Mastication of natural rubber

[0045] The natural rubber with a molecular weight distribution between 30,000 and 30 million is mechanically masticated by equipment such as an open mixer, internal mixer or screw plastic mixer to break the main chain, thereby reducing the viscosity of the natural rubber and increasing its Good dispersion of fillers and compounding agents increases plasticity and improves processing performance. There are no specific restrictions on the equipment and time of mastication. For example, the number of mastication times on the open mill is generally 50-65 times, and the plasticity is preferably 70-80.

[0046] b. Mixing of natural rubber with silica powder, petrolatum, anti-aging agent and other additives

[0047] The natural rubber masticated rubber obtained after mastication,...

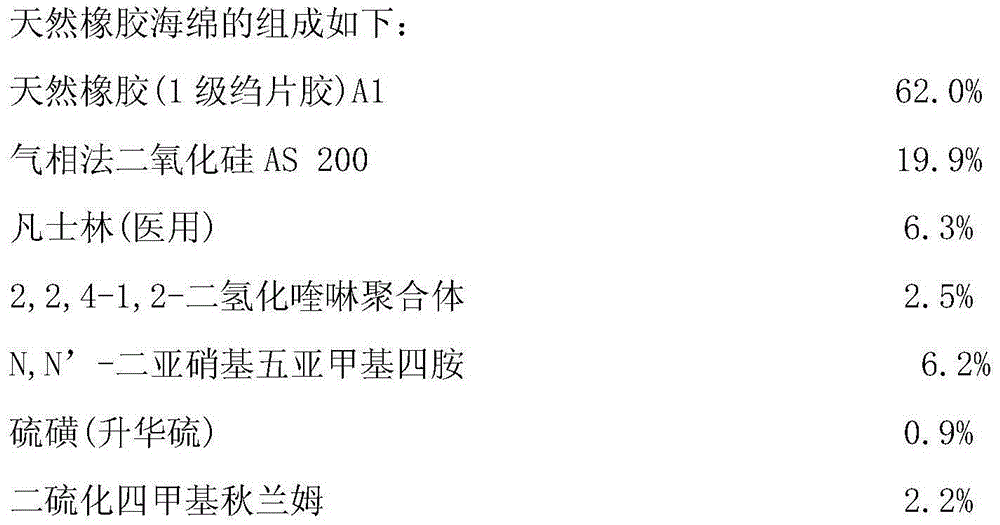

Embodiment 1

[0057]

[0058] At room temperature, add the grade 1 crepe rubber into the rubber refining type double-roller open mill, and carry out mastication under the condition of passing cooling water. The mastication is carried out in 4 times, and the number of times for each time is about 16 times. Thereby obtaining the natural rubber mastication rubber with a plasticity of 70-80.

[0059] In the rubber refining type double-roller open mill, add fumed silicon dioxide AS200 (trade name, manufactured by Shenyang Chemical Plant) with a BET specific surface area of 200m2 / g and medical vaseline to the natural rubber plastic compound, and disperse evenly , then add 2,5-dimethyl-2,5-di-tert-butylperoxyhexane to disperse evenly, then add 2,2,4-1,2-dihydroquinoline polymer (abbreviated as antioxidant RD) , and the natural rubber sponge masterbatch is obtained after uniform dispersion. After the rubber material is cooled to room temperature, add N,N'-dinitrosopentamethylenetetramine (foa...

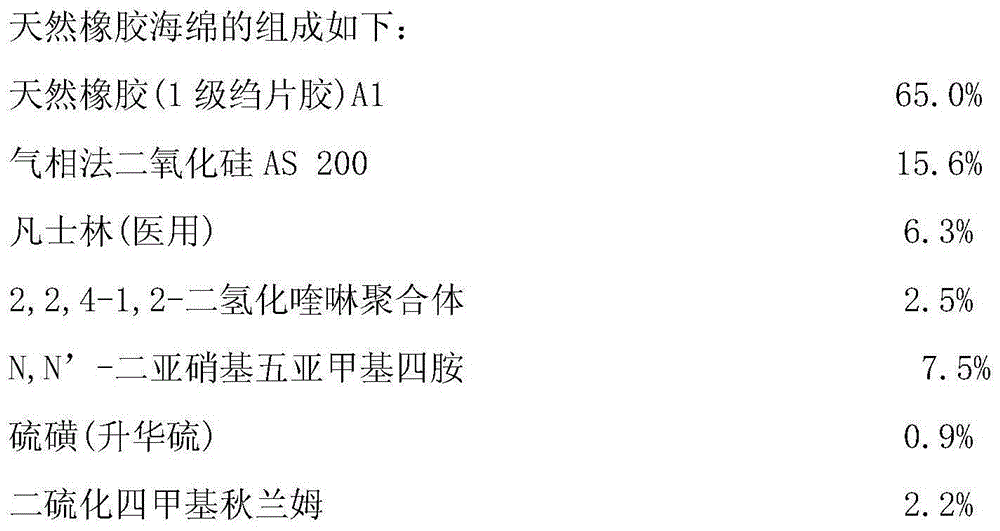

Embodiment 2

[0063]

[0064] According to the given content of each component, the method of Example 1 was repeated, but the vulcanization and foaming temperature was 143° C., and the molding time was 8 minutes.

[0065] The natural rubber sponge was made into various samples after precision slicing, and its composition and physical and mechanical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com